A kind of aluminum alloy profile and preparation technology thereof

An aluminum alloy profile and aluminum alloy technology, which is applied in the field of aluminum alloy profiles, can solve the problems of high cost and heat treatment energy consumption, and achieve the effects of reducing production cost, beautifying appearance and good scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

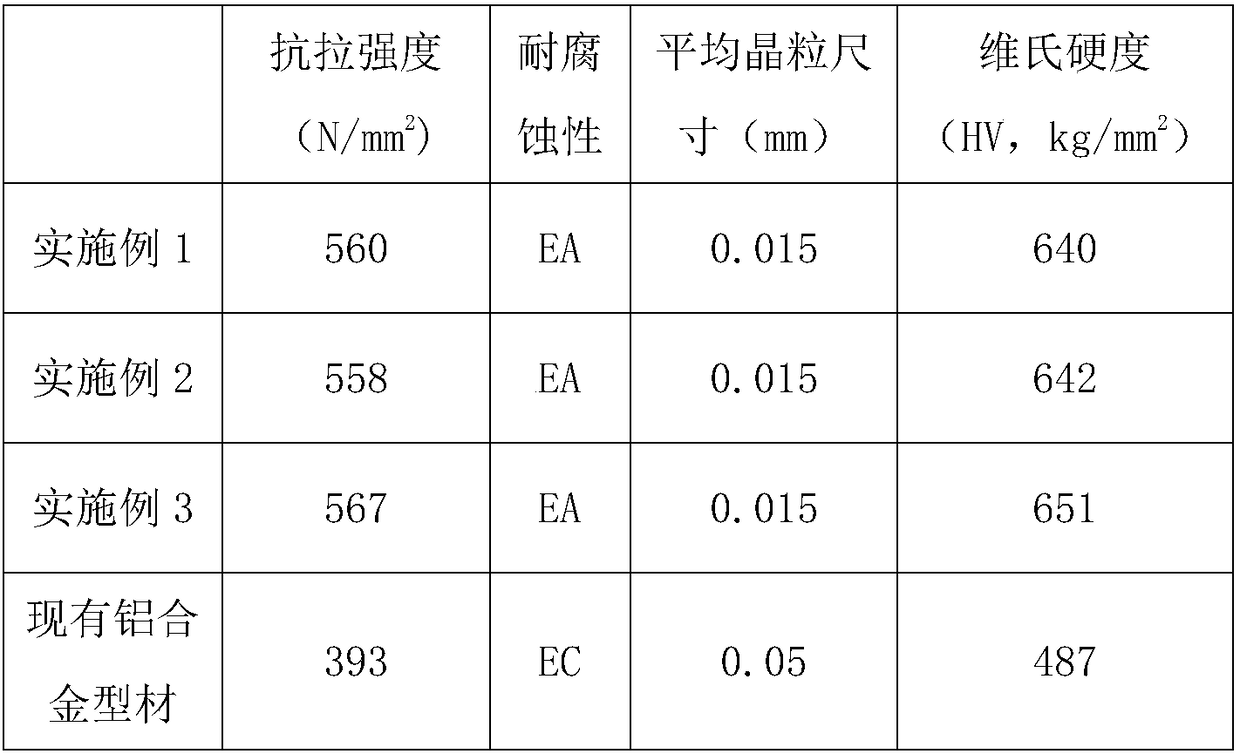

Examples

Embodiment 1

[0034] An aluminum alloy profile, comprising an aluminum alloy substrate, a protective layer, a paint coating and a varnish coating, the surface of the aluminum alloy substrate is coated with a protective layer, the surface of the protective layer is coated with a paint coating, the color The surface of the lacquer coating is coated with a varnish coating; it is characterized in that the aluminum alloy substrate is composed of the following raw materials in parts by weight:

[0035] 10 parts of chromium, 10 parts of nickel, 5 parts of silicon, 0.5 parts of iron, 1 part of manganese, 1 part of magnesium, 1 part of zinc, 0.5 parts of titanium, 0.1 part of lead, 0.01 part of cadmium, and the rest is aluminum.

[0036] The paint coating comprises the following raw materials:

[0037] 35 parts of resin, 20 parts of monomer, 4 parts of photoinitiator, 25 parts of diluent, 0.5 part of leveling agent and 2 parts of color essence.

[0038] The preparation method of described colored p...

Embodiment 2

[0058] An aluminum alloy profile, comprising an aluminum alloy substrate, a protective layer, a paint coating and a varnish coating, the surface of the aluminum alloy substrate is coated with a protective layer, the surface of the protective layer is coated with a paint coating, the color The surface of the lacquer coating is coated with a varnish coating; it is characterized in that the aluminum alloy substrate is composed of the following raw materials in parts by weight:

[0059] 15 parts of chromium, 15 parts of nickel, 10 parts of silicon, 1 part of iron, 2 parts of manganese, 2 parts of magnesium, 2 parts of zinc, 1 part of titanium, 0.3 parts of lead, 0.03 parts of cadmium, and the rest are aluminum.

[0060] The paint coating comprises the following raw materials:

[0061] 40 parts of resin, 25 parts of monomer, 6 parts of photoinitiator, 30 parts of diluent, 1 part of leveling agent and 3 parts of color essence.

[0062] The preparation method of described colored pa...

Embodiment 3

[0082] An aluminum alloy profile, comprising an aluminum alloy substrate, a protective layer, a paint coating and a varnish coating, the surface of the aluminum alloy substrate is coated with a protective layer, the surface of the protective layer is coated with a paint coating, the color The surface of the lacquer coating is coated with a varnish coating; it is characterized in that the aluminum alloy substrate is composed of the following raw materials in parts by weight:

[0083] 13 parts of chromium, 13 parts of nickel, 8 parts of silicon, 0.8 parts of iron, 1.5 parts of manganese, 1.5 parts of magnesium, 1.5 parts of zinc, 0.8 parts of titanium, 0.2 parts of lead, 0.02 parts of cadmium, and the rest are aluminum.

[0084] The paint coating comprises the following raw materials:

[0085] 38 parts of resin, 23 parts of monomer, 5 parts of photoinitiator, 28 parts of diluent, 0.8 part of leveling agent and 2.5 parts of color essence.

[0086] The preparation method of descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com