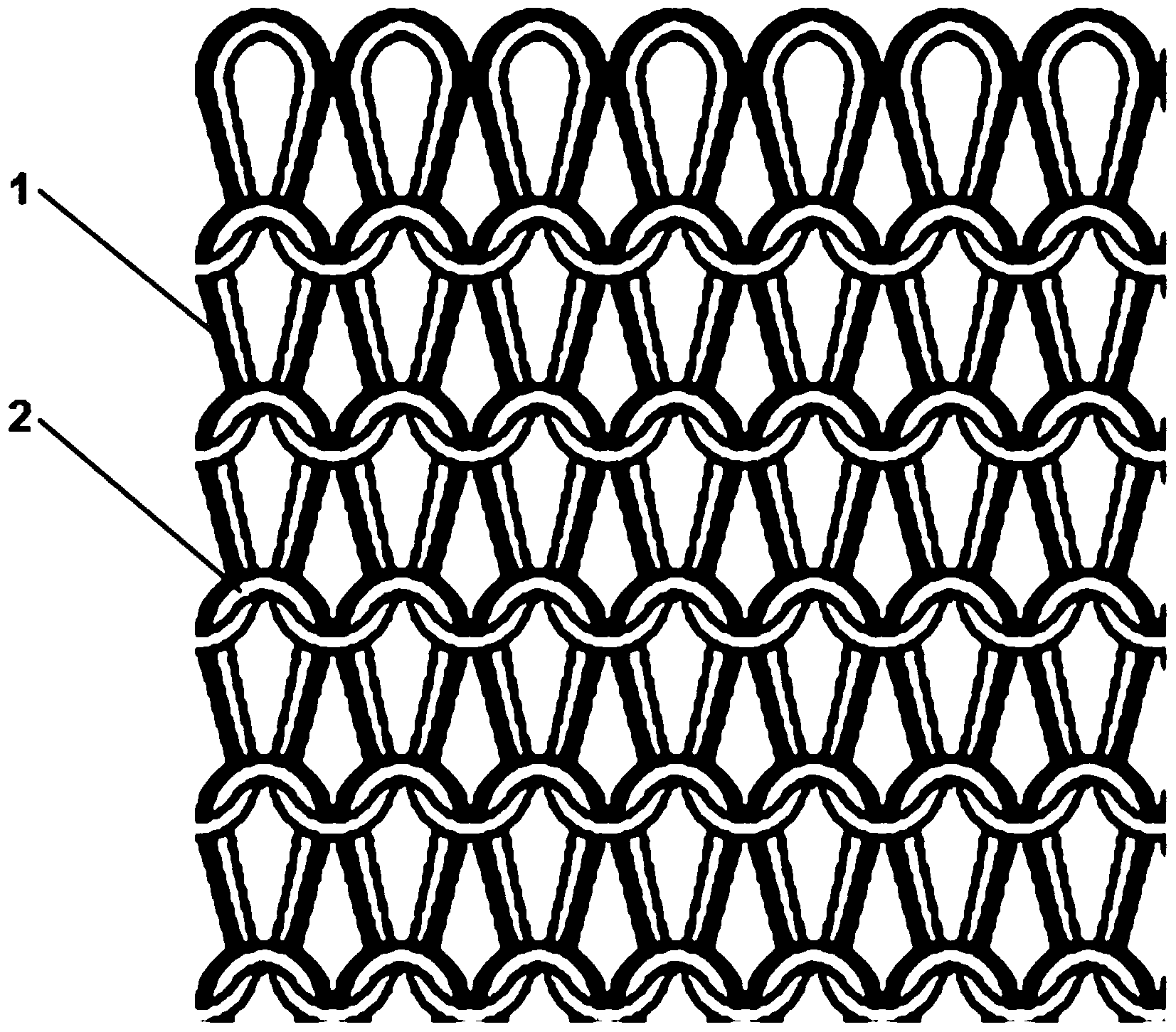

Purl high-density functional knitted fabric and manufacturing method thereof

A technology for knitted fabrics and manufacturing methods, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of poor hand feeling, easy to generate static electricity, and insolation resistance of all polyester underwear fabrics, and achieve good moisture absorption and moisture dissipation. , Solve the effect of poor strength and full appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The high-needle and high-density functional knitted underwear fabric of the present invention is obtained through the following steps:

[0032] Step 1. Preparation of raw materials: 80S superfine regenerated cellulose fiber, 40D superfine polyester filament, and 15D superfine spandex filament.

[0033] Step 2. Weaving on the machine: choose a machine number of 36G large circular machine to weave, arrange the superfine regenerated cellulose fiber and superfine polyester filament one by one, and weave with superfine spandex filament by plating process; superfine regenerated cellulose The tension on the fiber and superfine polyester filament machine is 5 grams, and ensure that the vertical angle of the superfine regenerated cellulose fiber and superfine polyester filament feeding needle hook is larger than the longitudinal angle of the spandex yarn feeding yarn, so as to ensure the superfine regenerated fiber Vegan and microfiber polyester filaments are on the front of the...

Embodiment 2

[0042] The high-needle and high-density functional knitted underwear fabric of the present invention is obtained through the following steps:

[0043] Step 1. Raw material preparation: 100S superfine regenerated cellulose fiber, 30D superfine polyester filament, 20D superfine spandex filament.

[0044] Step 2. Weaving on the machine: choose a machine number of 36G large circular machine to weave, arrange the superfine regenerated cellulose fiber and superfine polyester filament one by one, and weave with superfine spandex filament by plating process; superfine regenerated cellulose The tension on the fiber and superfine polyester filament machine is 5 grams, and ensure that the vertical angle of the superfine regenerated cellulose fiber and superfine polyester filament feeding needle hook is larger than the longitudinal angle of the spandex yarn feeding yarn, so as to ensure the superfine regenerated fiber Vegan and microfiber polyester filaments are on the front of the fabric...

Embodiment 3

[0053] The high-needle and high-density functional knitted underwear fabric of the present invention is obtained through the following steps:

[0054] Step 1. Raw material preparation: 120S superfine regenerated cellulose fiber, 20D superfine polyester filament, 25D superfine spandex filament.

[0055] Step 2. Weaving on the machine: choose a machine number of 36G large circular machine to weave, arrange the superfine regenerated cellulose fiber and superfine polyester filament one by one, and weave with superfine spandex filament by plating process; superfine regenerated cellulose The tension on the fiber and superfine polyester filament machine is 5 grams, and ensure that the vertical angle of the superfine regenerated cellulose fiber and superfine polyester filament feeding needle hook is larger than the longitudinal angle of the spandex yarn feeding yarn, so as to ensure the superfine regenerated fiber Vegan and microfiber polyester filaments are on the front of the fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com