Two-stage drive complex high-frequency vibration sieve

A technology of compound vibration and high-frequency sieve, which is applied in the direction of mobile filter element filter, filter separation, separation method, etc., to achieve the effect of reducing the quality of vibration, convenient adjustment and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

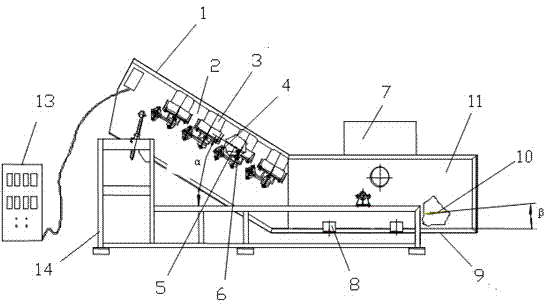

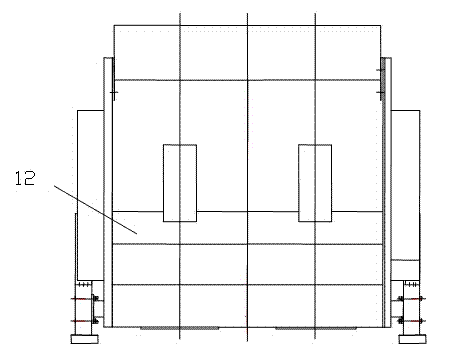

[0020] The high-frequency vibrating screen of the present invention is divided into two sections: the upper section of the high-frequency screen and the lower section 9 of the high-frequency screen. The vibrating devices installed in the upper section of the high-frequency screen 1 and the lower section 9 of the high-frequency screen are independently driven, and the two sections are independent units. They are connected together by the elastic device 8 to interact and influence each other to achieve a novel compound vibration effect.

[0021] The figure shows that the upper section 1 of the high-frequency screen is installed at a large positive angle with the feed end higher than the discharge end, and the lower section 9 of the high-frequency screen adopts a small positive angle or a small positive angle between the feed end and the discharge end or the feed end is lower than the discharge end. Negative angle installation. The installation angle α of the upper screen or sieve p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com