Three-layer rotor crusher

A crusher and rotor technology, applied in grain processing, etc., can solve the problems of inconvenient installation and maintenance, large volume of counter-attack liner, uneven wear, etc., and achieve the effect of easy installation and maintenance, compact structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

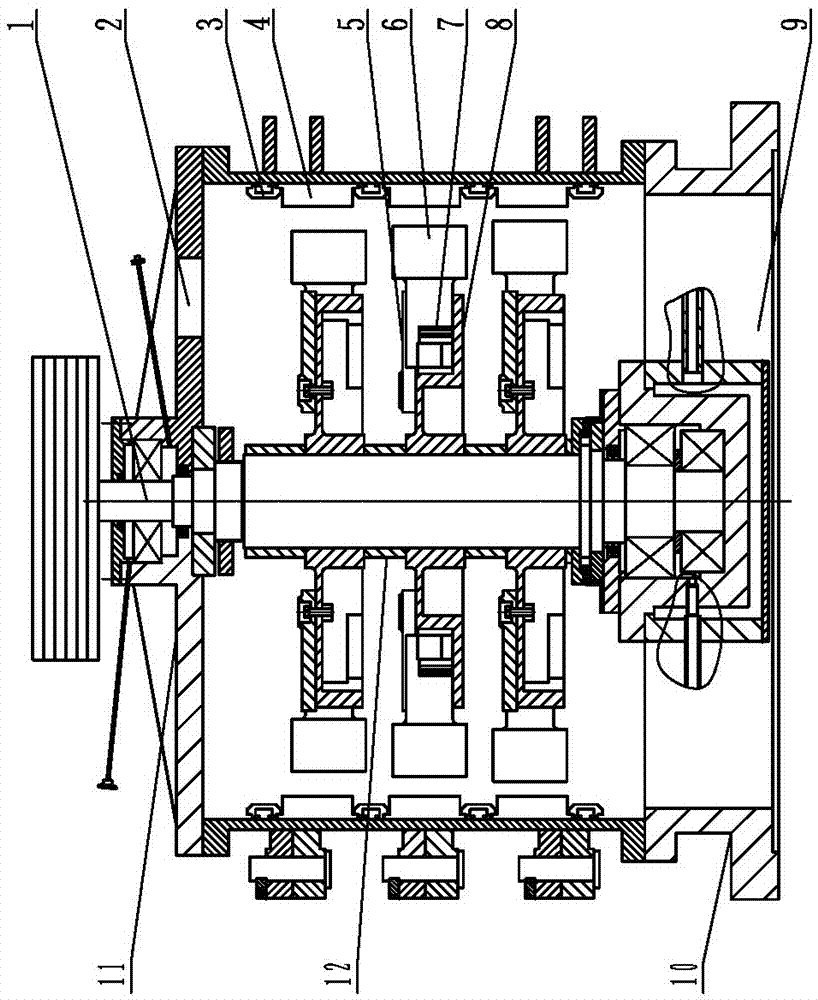

[0024] Such as figure 1 As shown, in the three-layer rotor crusher of the present invention, an upper cover 11 is installed on the upper part of the crusher cylinder, and the upper cover 11 is provided with a feed port 2 . A base 10 is installed on the lower part of the crusher barrel, and a discharge port 9 is opened on the base 10 .

[0025] The main shaft 1 is installed in the cylinder, and the three-layer rotor body 8 is installed on the main shaft 1. The shaft sleeve 12 is placed on the main shaft 1 between the rotor bodies 8. By changing the length of the shaft sleeve 12, the distance between the rotor bodies 8 is changed. The rotor body guard plate 5 is installed on the rotor body 8 . On the inner wall of the crusher cylinder, three layers of ring-shaped counter-attack linings are installed by using bolts, nuts and lining strips 3, and each counter-attack lining layer contains 12 wear-resistant counter-attack linings 4 to protect the cylinder. . The working surface o...

Embodiment 2

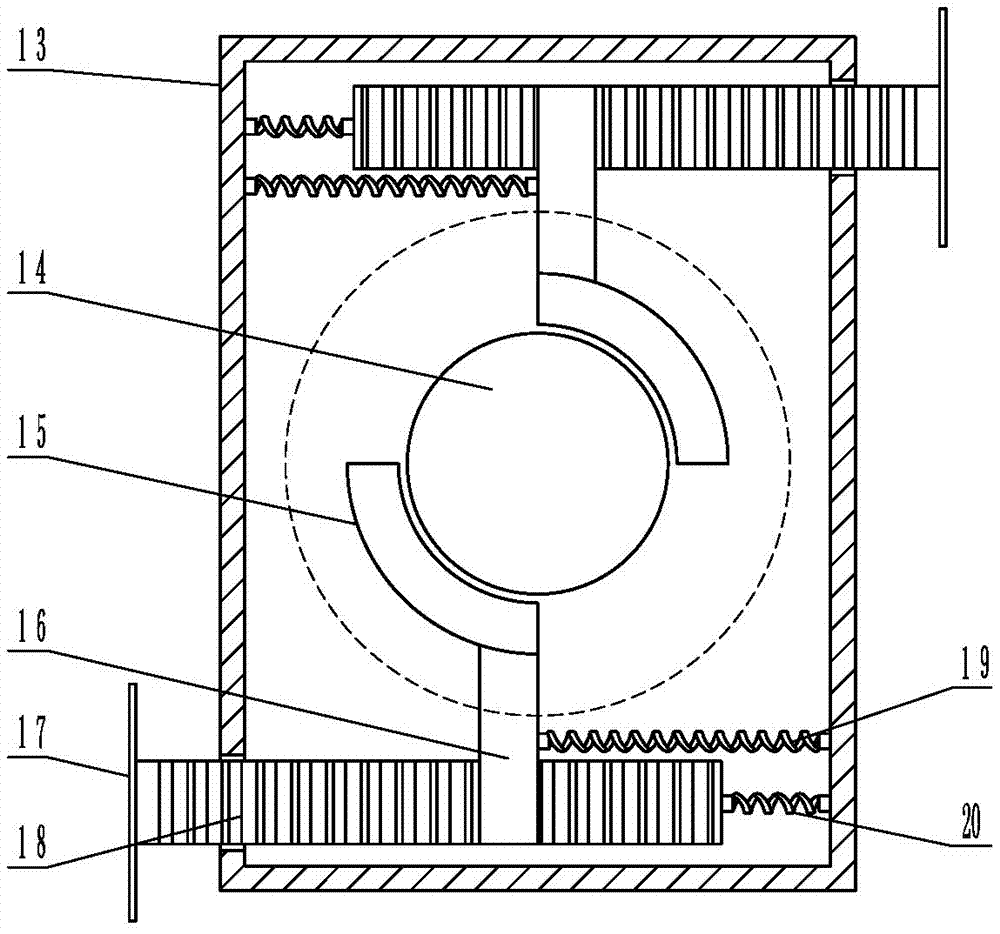

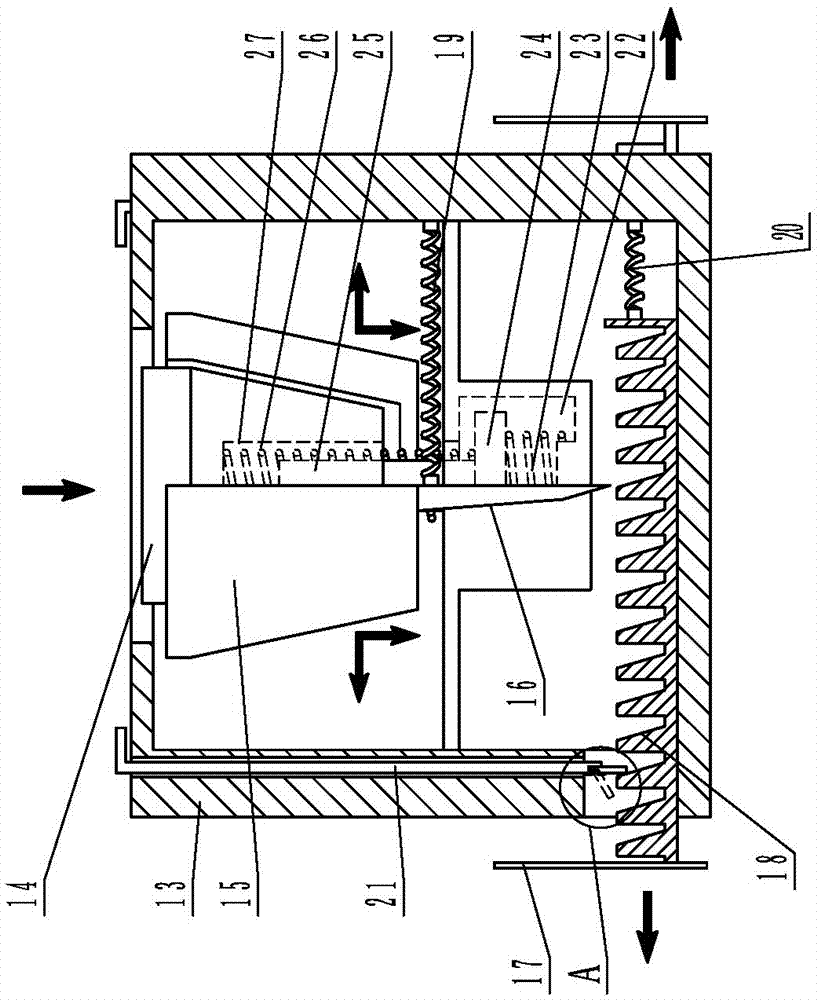

[0030] Such as Figure 2-4As shown, in this embodiment, the adjustment device is a push-type gap adjuster. The push-type gap adjuster includes a housing 13, and a frustum-shaped adjustment block 14 with a large top and a small bottom is arranged in the casing 13. The bottom surface of the adjustment block 14 is provided with a level The spring groove 27 is provided with a primary spring 26 in the spring groove, and the primary spring 26 is sleeved on the spring column 25, and the lower end of the spring column 25 is installed on the column platform 24; the secondary spring groove 22 is set below the adjustment block 14, A secondary spring 23 is arranged in the secondary spring groove 22, and the upper end of the secondary spring 23 bears against the lower surface of the column base 24; it also includes two movable blocks 15 with an "L" shape in cross section, and the movable block 15 is arranged on the adjustment block 14 The two sides of the movable block 15 and the adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com