Rapid wall base demounting and mounting component and method and lifting rod

A wall seat, fast technology, applied in the direction of spray device, water supply device, indoor sanitary pipe device, etc., can solve the problems of cumbersome and many installation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

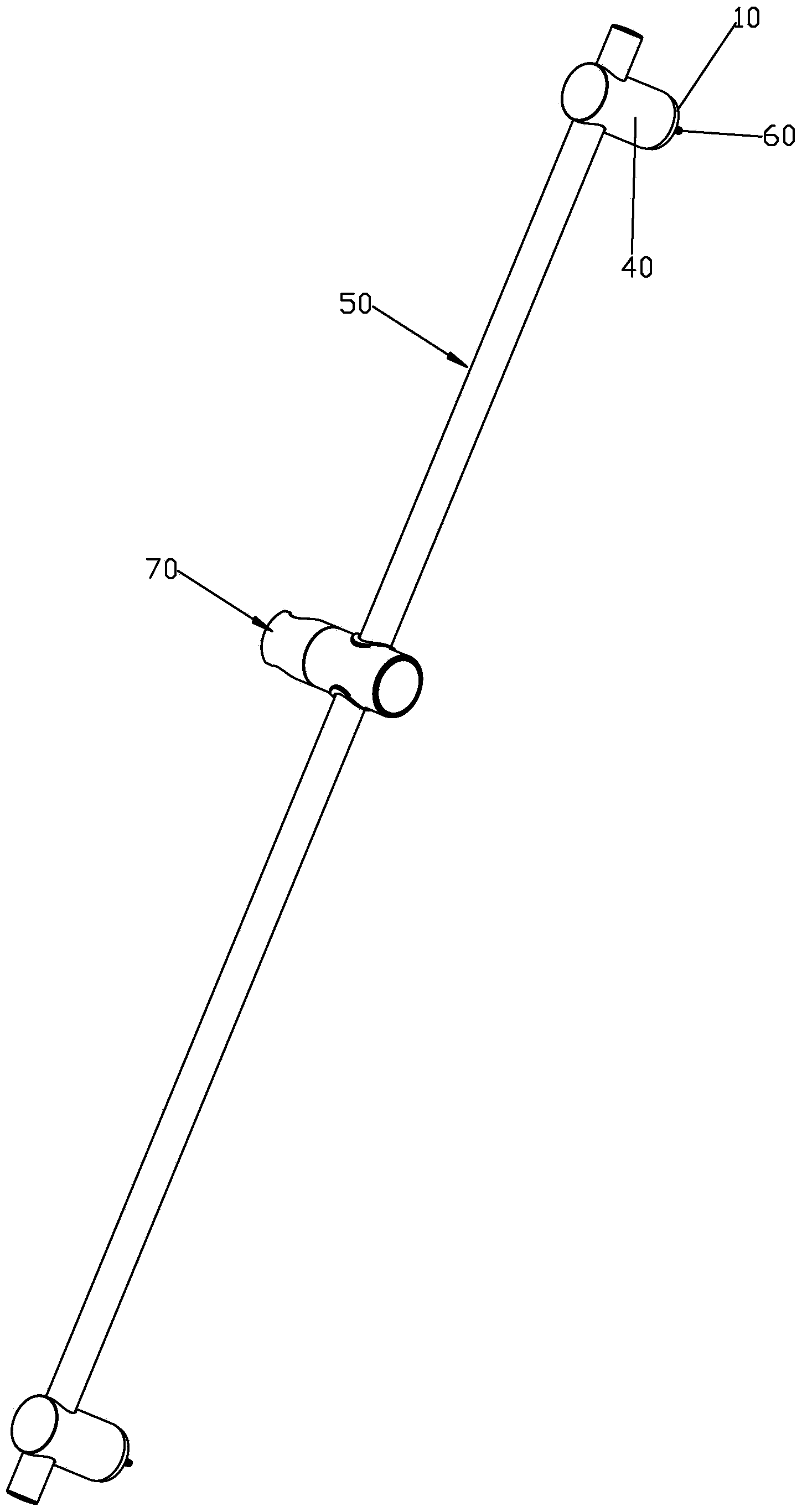

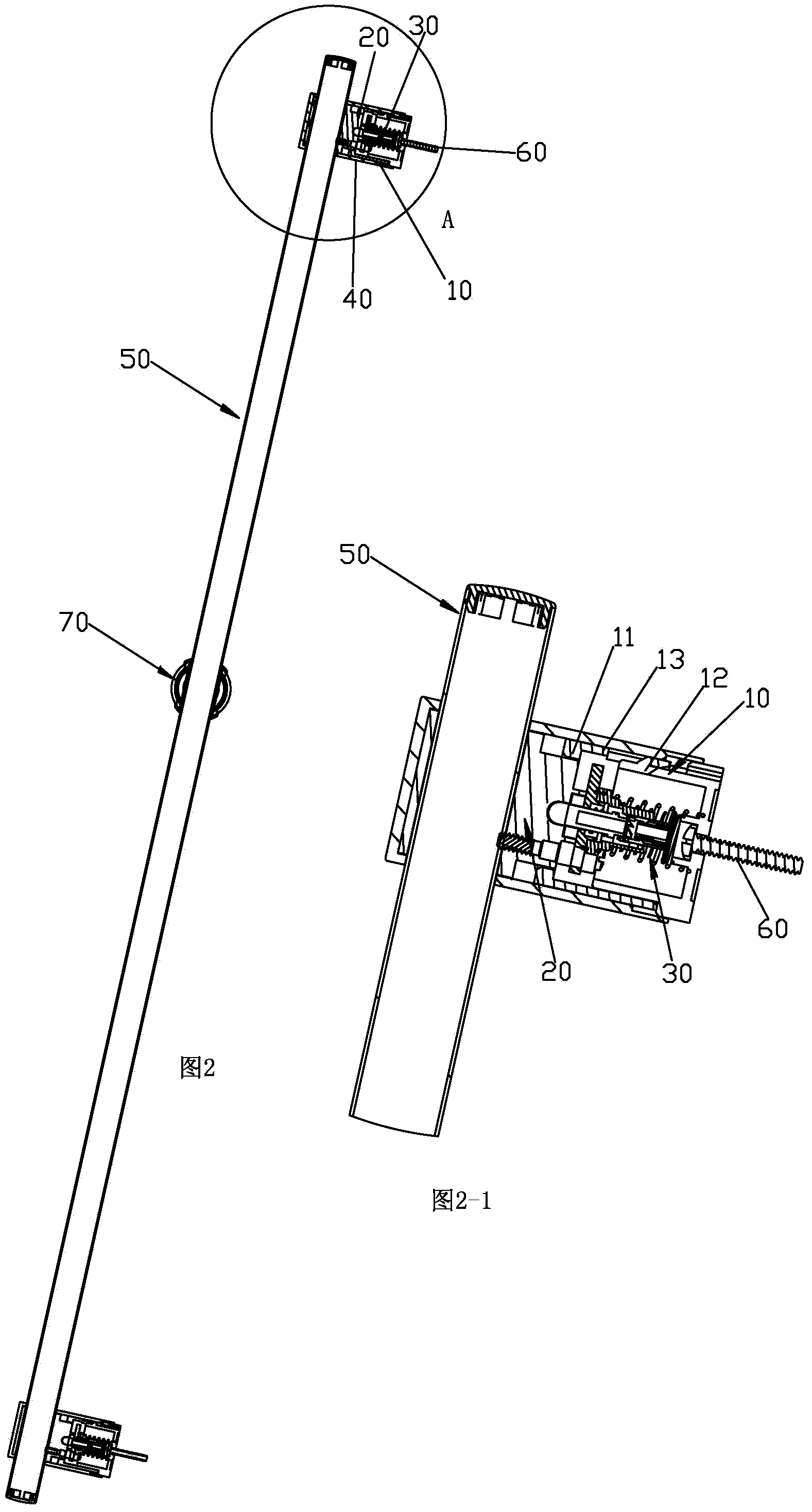

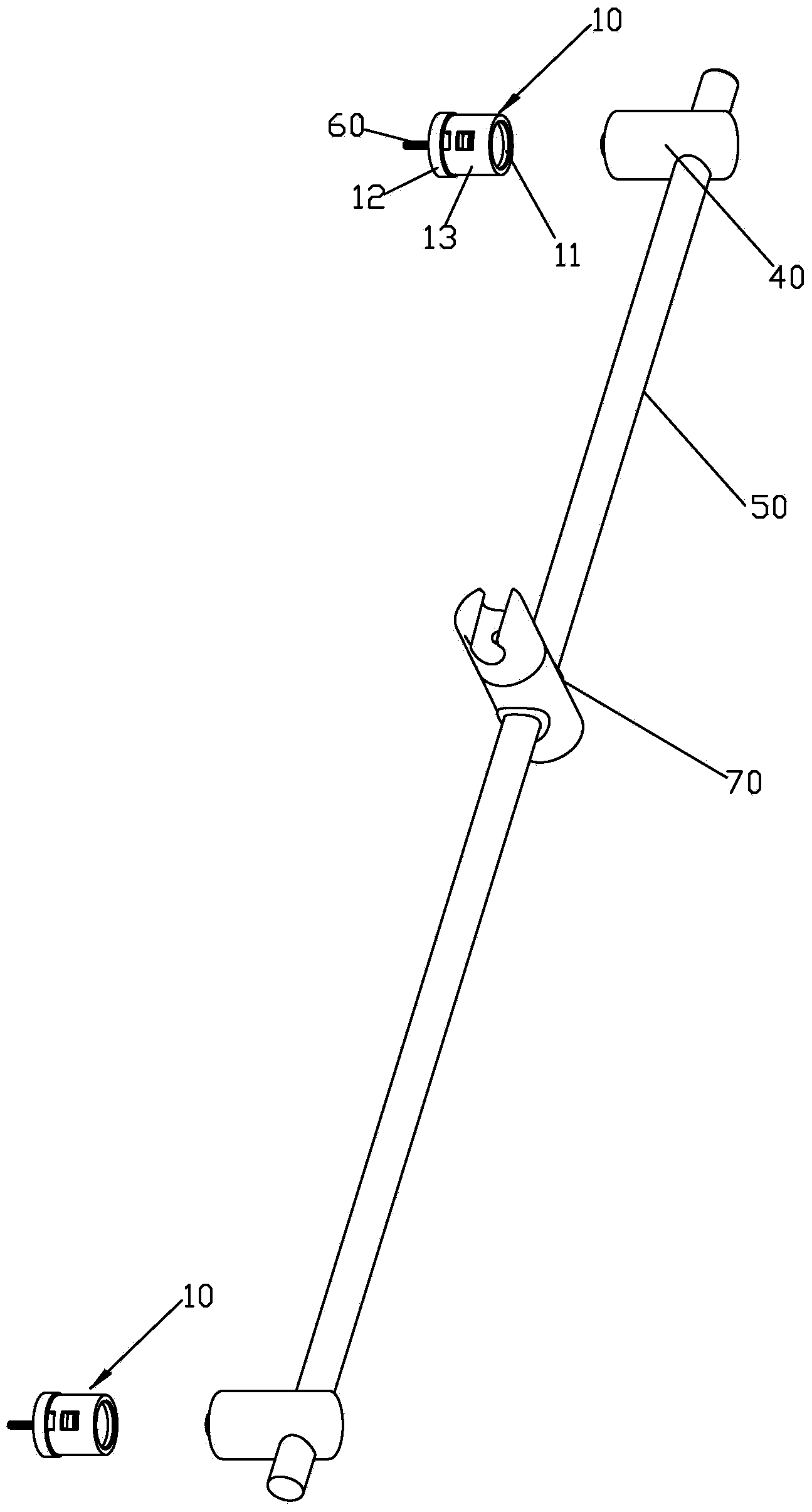

[0039] Please check Figure 1 to Figure 6 , a quick detachable wall seat assembly, including a solid seat 10 and an attachment seat 20.

[0040] The fixed seat 10 is concavely provided with an installation cavity, and the mouth of the installation cavity protrudes inwardly and is provided with a hanging platform 11 , and an opening is formed in the hanging platform 11 . In this embodiment, the fixed seat 10 includes a base 12 and a sleeve 13. The base 12 includes a bottom wall and a peripheral wall extending from the periphery of the bottom wall in a direction perpendicular to the bottom wall. The sleeve 13 is fixedly attached to the peripheral wall. In addition, the port of the sleeve 13 is the cavity, and the base 12 and the sleeve 13 form the installation cavity. According to requirements, the surrounding wall is provided with a stepped structure, and the sleeve is fixed to the outside of the small diameter of the surrounding wall and the end is located at the stepped surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com