Roller-type leveler for metal plate

A leveling machine and metal plate technology, which is applied in the field of plate leveling machinery, can solve problems such as uneven workpieces, and achieve the effects of good environmental performance, low noise, and low power consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

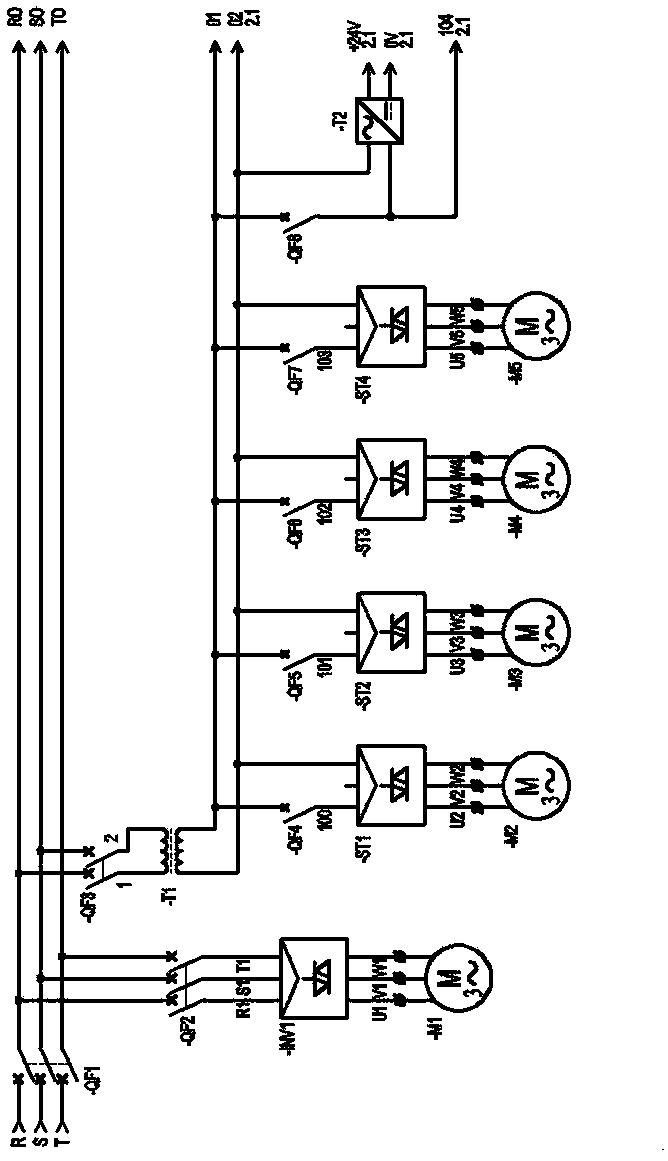

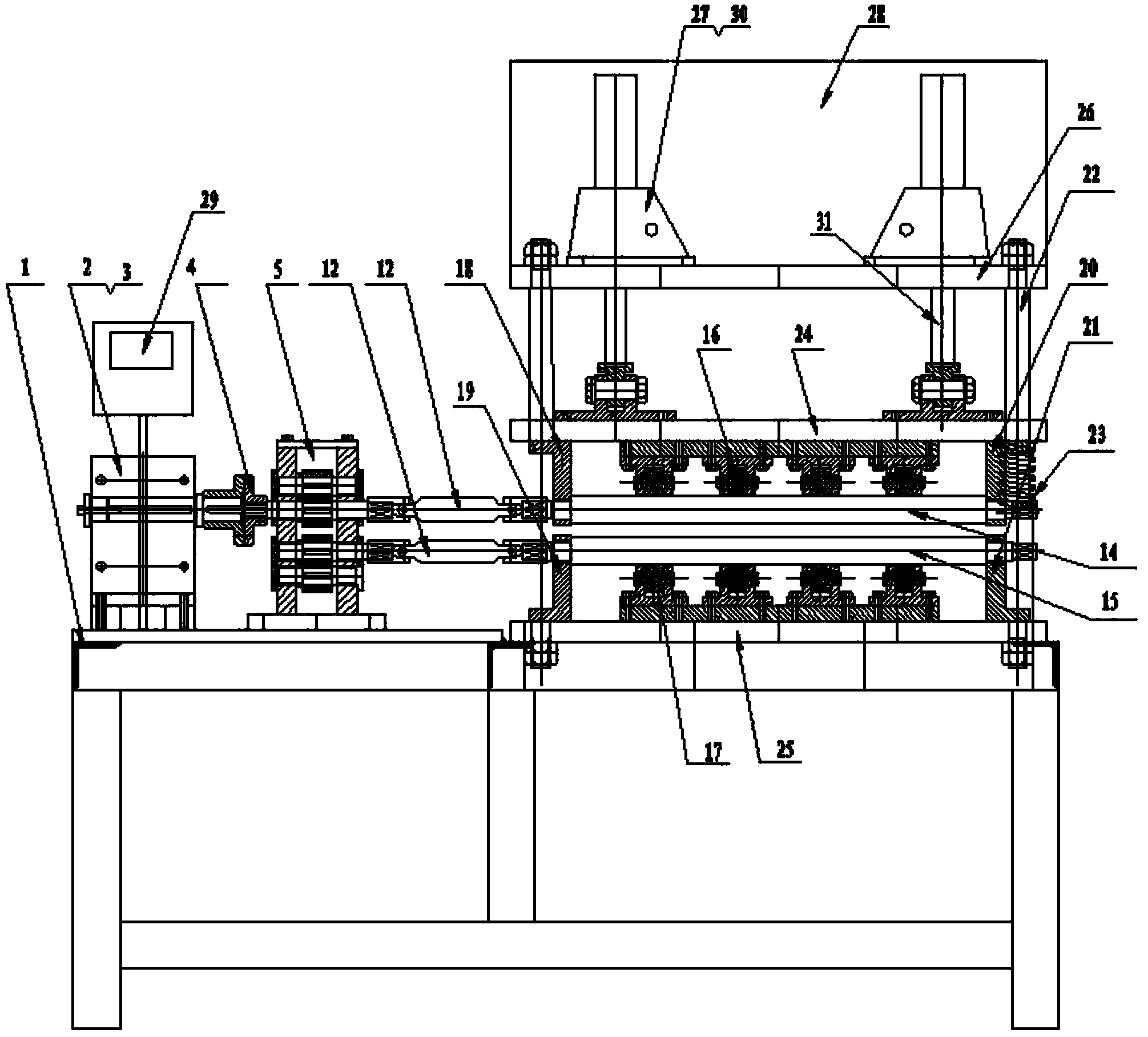

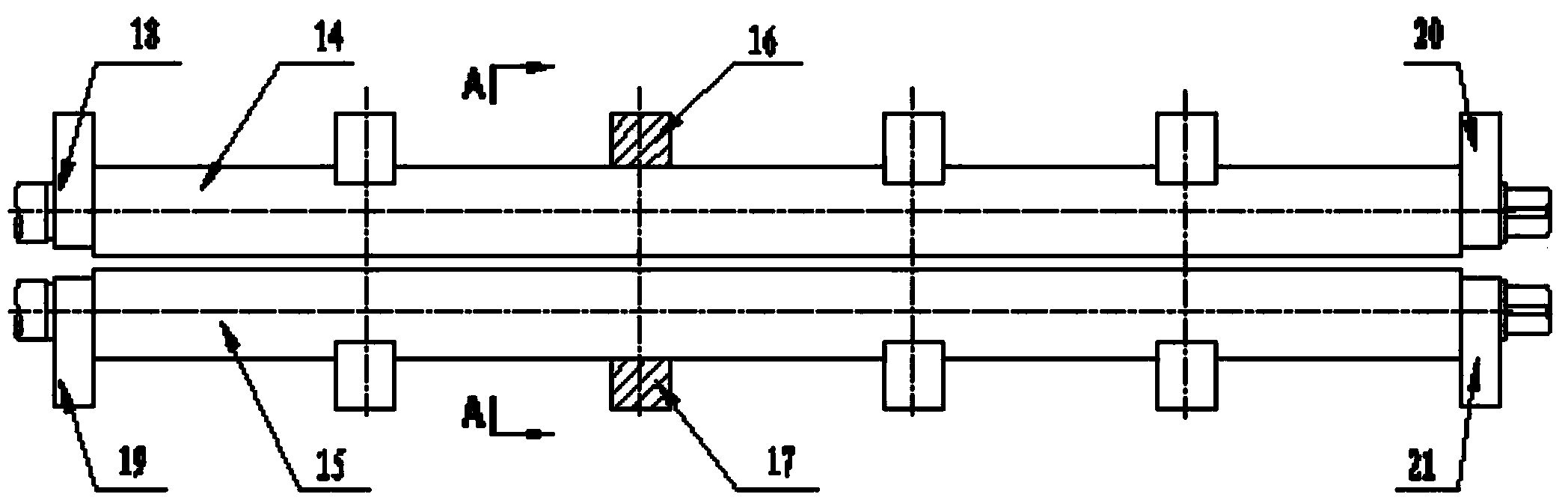

[0027] Such as figure 1 As shown, the metal plate roller leveler of the present invention includes a fuselage 1, a motor 2, a reduction box 3, a flange 4, a power gearbox 5, an upper leveling stick 14, a lower leveling stick 15, a movable beam 24, a lower leveling Fixed seat 25, upper fixed seat 26, protective cover 28, support and stepping motion mechanism. Reduction box 3, power gear box 5, lower fixing seat 25 are respectively fixed on the fuselage 1, and upper fixing seat 26 is connected on the top of lower fixing seat 25 by four guide posts 22. Every guide post 22 is sheathed with a spring 23 to ensure smooth operation when rolling the flattened plate, and can eliminate the gap of the stepping motor 27. Protective cover 28 is located at the upper end of stepping motion mechanism. The step motion mechanism comprises a step motor 27, a lift reducer 30 and a digital operation panel 29, the step motor 27 and the lift reducer 30 form a synchronous rotating assembly, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com