Sinker electric discharge machining apparatus

一种成型加工、电火花的技术,应用在电动加工设备、附属装置、金属加工设备等方向,能够解决主轴重量增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

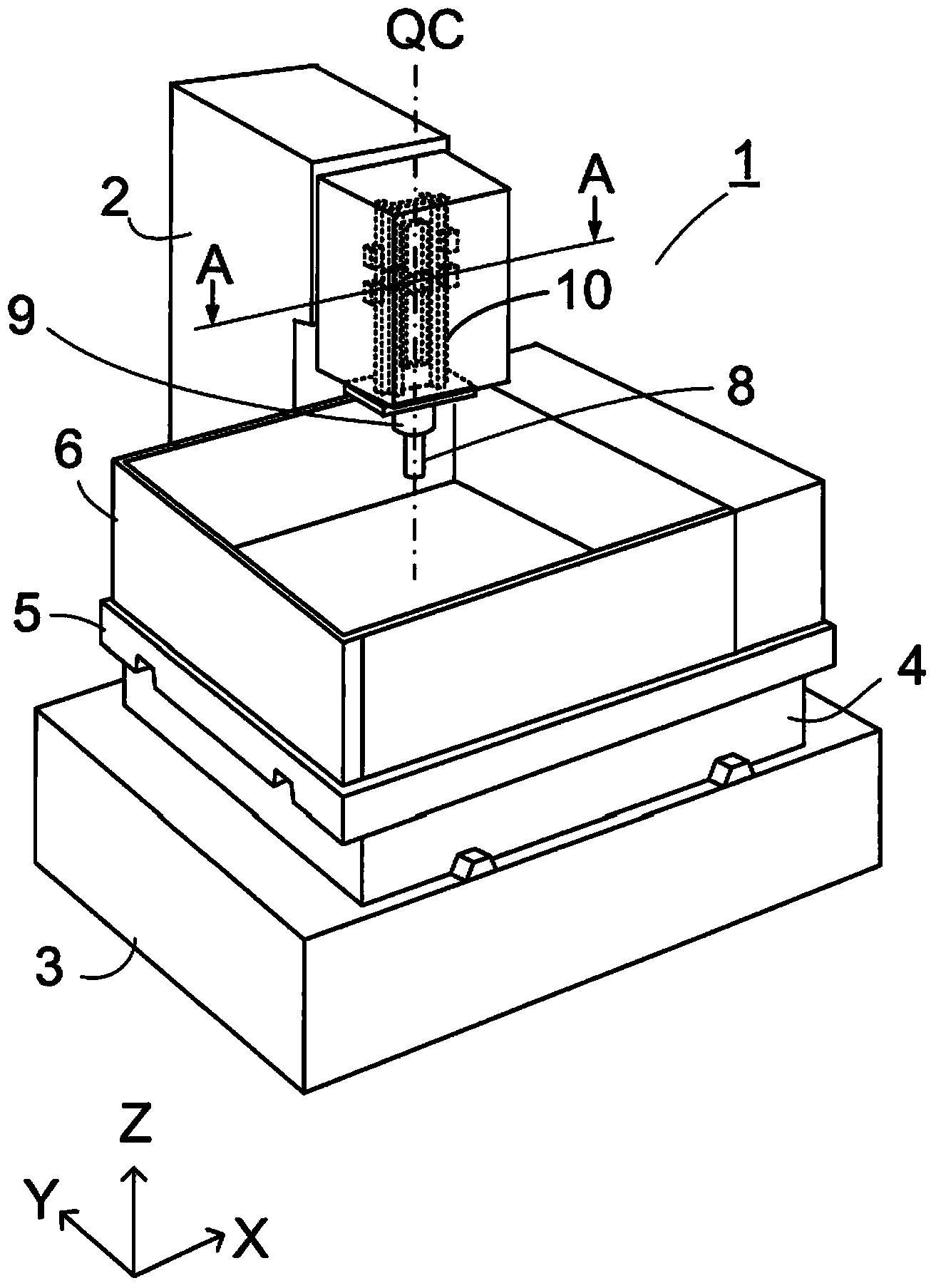

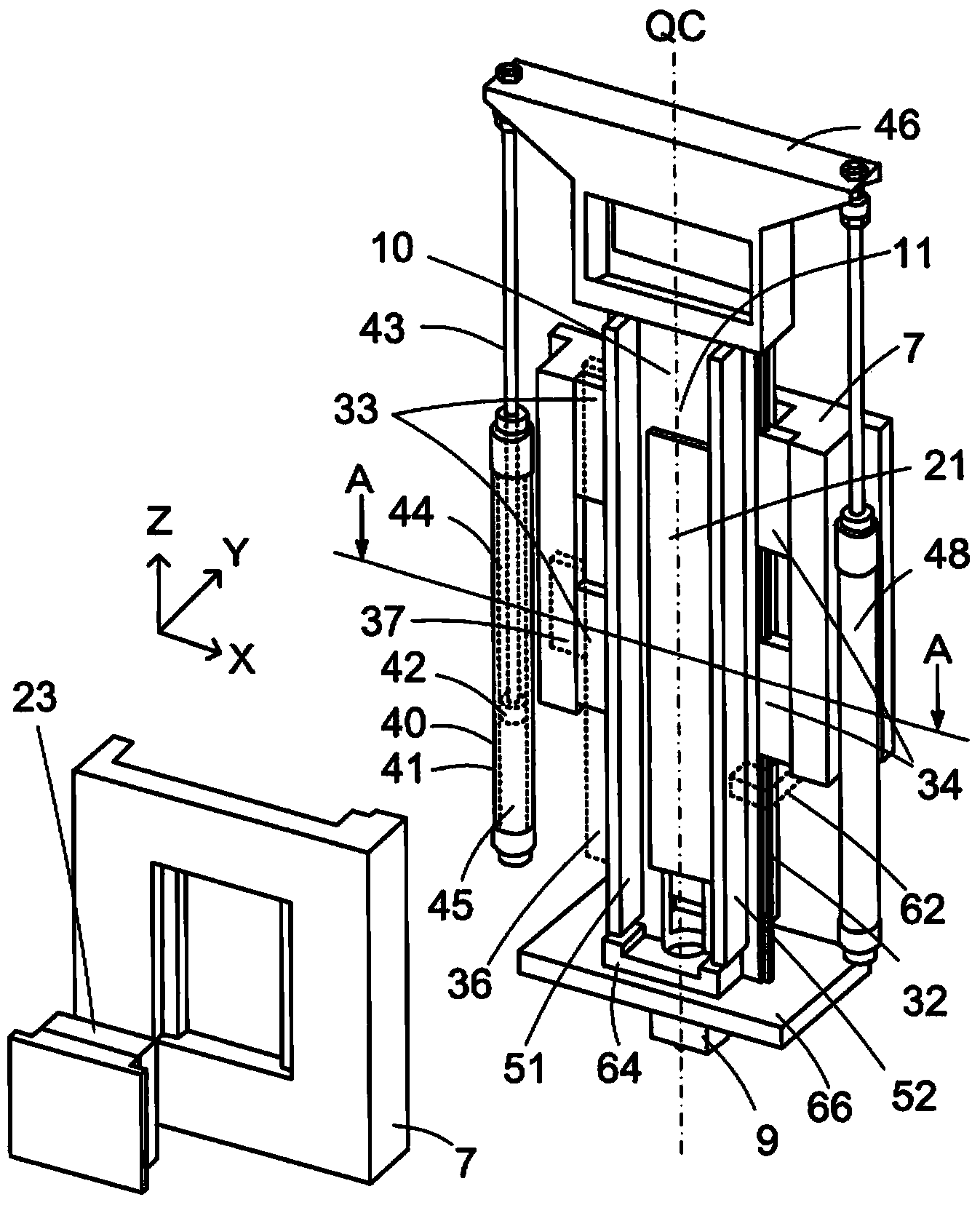

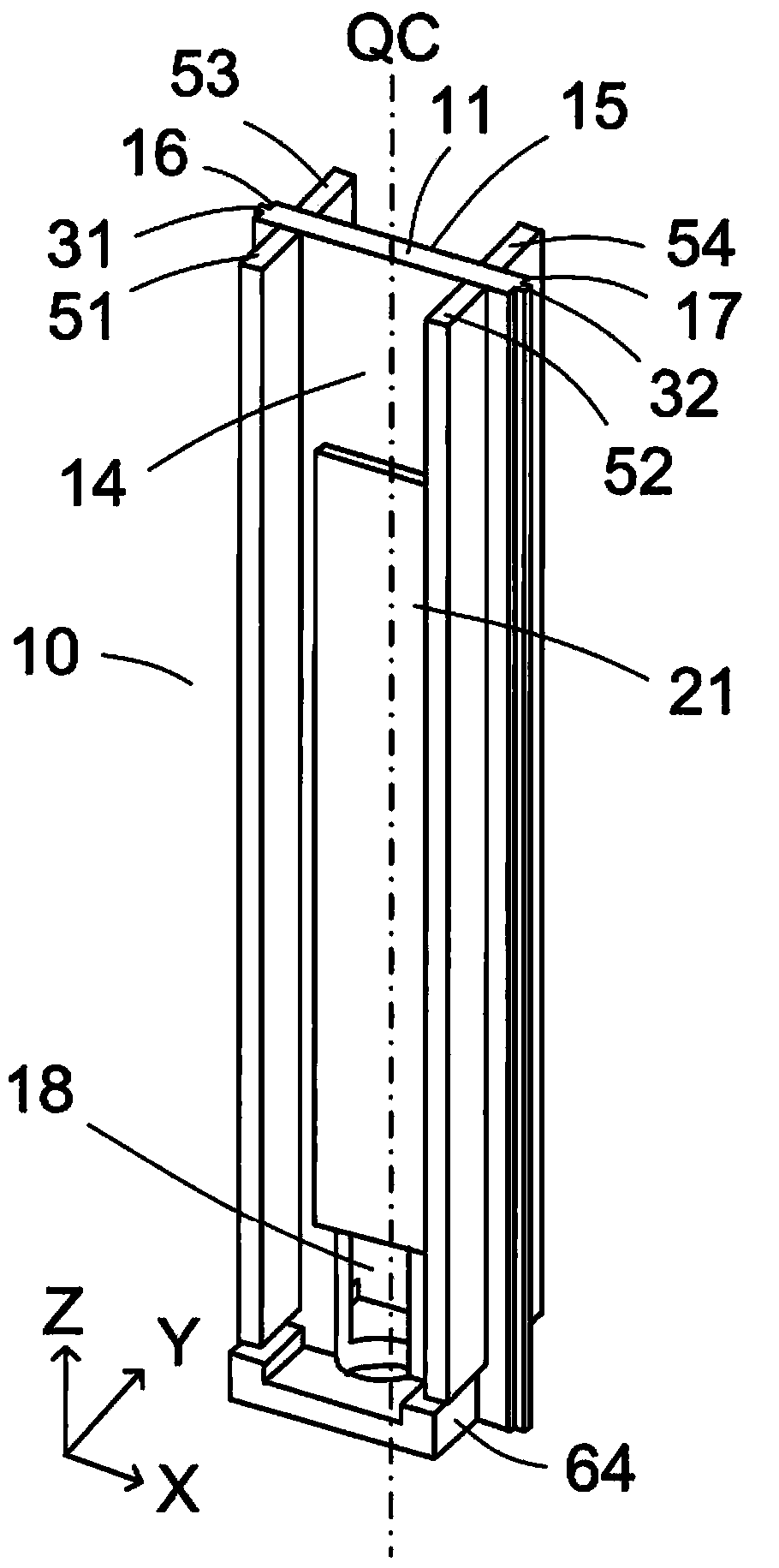

[0056] Below, refer to Figure 1 to Figure 4 The electrical discharge machining device of the present invention will be described. Such as figure 1 As shown, a column (column) 2 is disposed behind a machine bed 3 , and a seat plate (saddle) 4 is provided on the machine bed 3 so as to be slidable along the Y-axis direction. A platform (table) 5 is slidably disposed on the seat plate 4 along the X-axis direction. A processing tank 6 is provided on the platform 5 , and a workpiece (not shown) is fixed in the processing tank 6 . Machining tank 6 is filled with EDM fluid during machining.

[0057] The holding member 7 is fixed to the front of the column 2 . The holding member 7 has a hole through which the main shaft 10 passes vertically. The spindle 10 is held by the holding member 7 so as to be movable in the Z-axis direction. The tool electrode 8 may be directly or indirectly attached to the lower end of the main shaft 10 . In the embodiment, the tool electrode 8 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com