Loading and temporary storage device for new fuel of pebble-bed high-temperature reactor

A technology for high-temperature reactors and fuels, which is applied in the direction of reactor fuel elements, reactors, and reduction of greenhouse gases. It can solve the difficulties of assembly, welding, and weld inspection, unrealistic maintenance and repair work, and the frequency of pipeline valve movements. Advanced problems, to achieve the effect of simplifying the overall layout and the support of various components and pipelines, shortening the installation work time and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

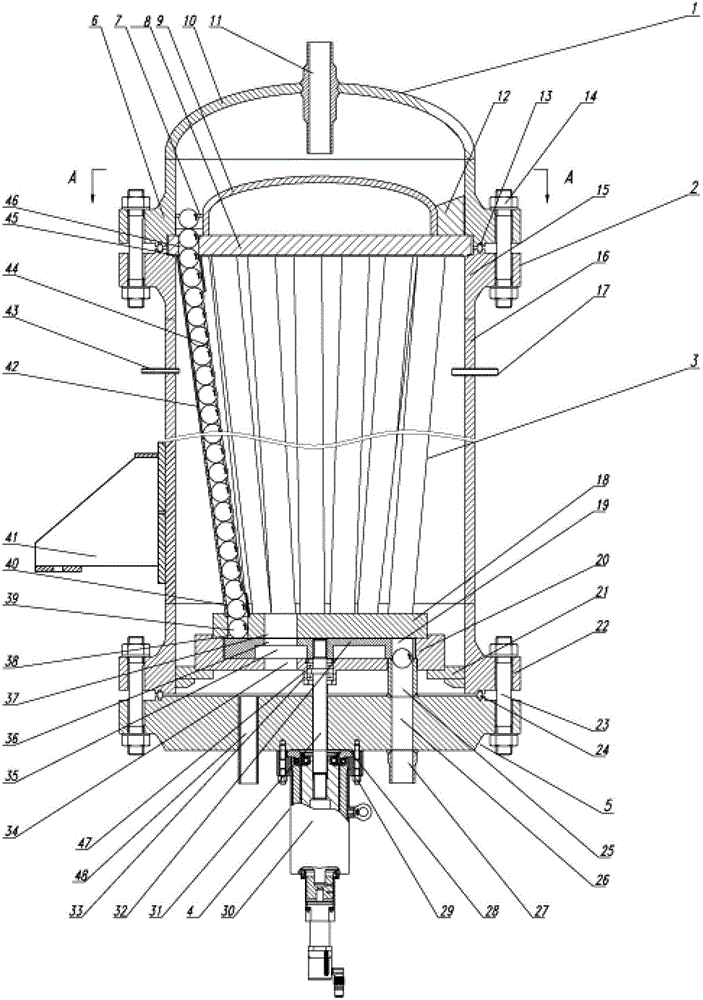

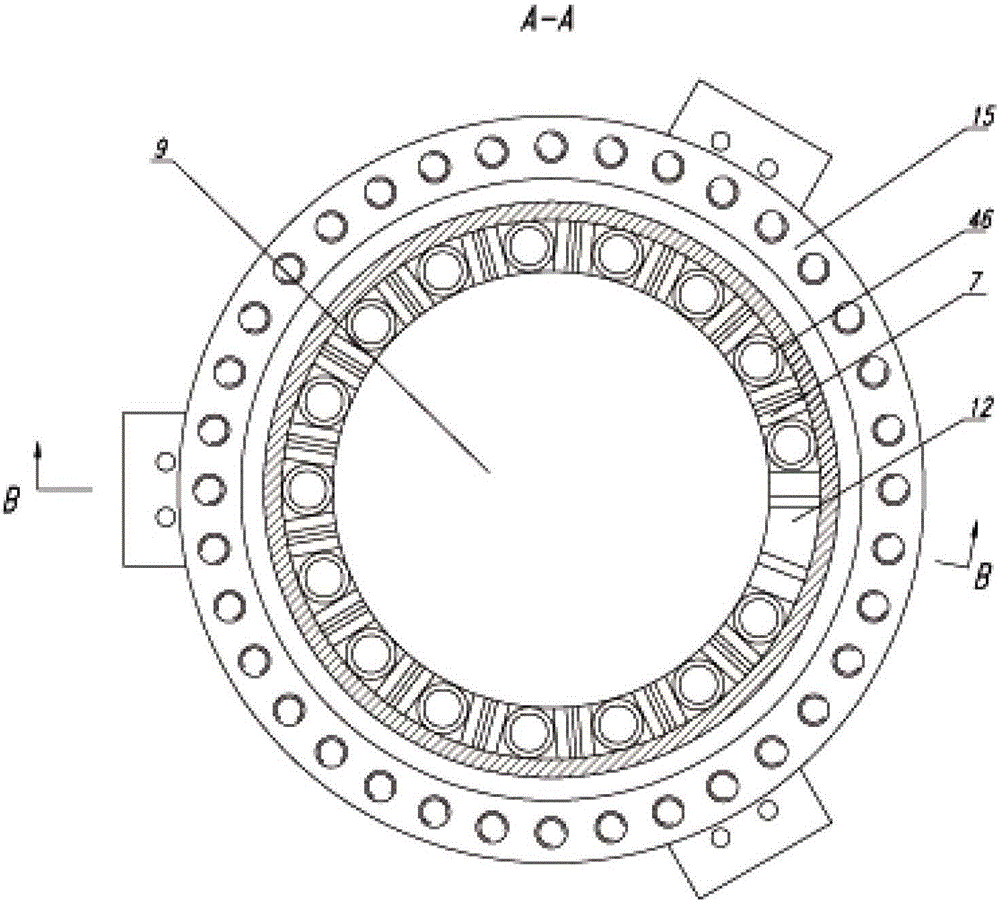

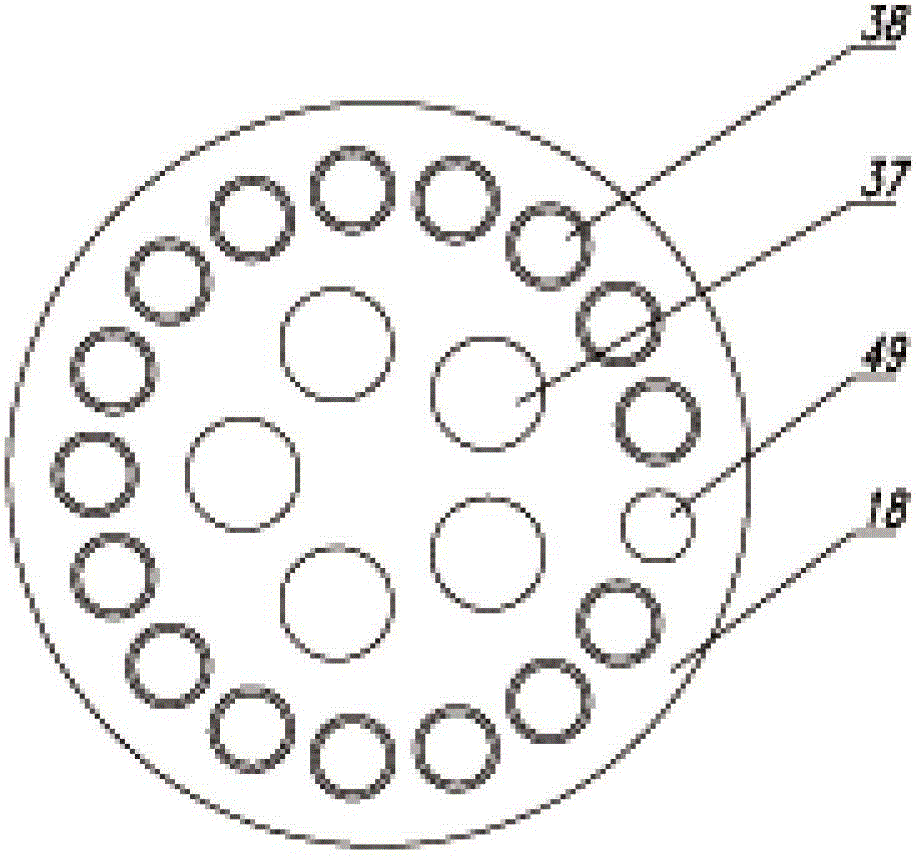

[0018] Such as figure 1 As shown, a new fuel charging temporary storage device for a pebble bed high temperature reactor in this embodiment, the new fuel charging temporary storage device is provided with an upper head assembly 1, a cylinder assembly 2 and a bottom surface in sequence from top to bottom Flange assembly 5, an inner support 21 is provided at the bottom of the cylinder assembly, a silo assembly 3 is provided inside the cylinder assembly, and a top partition 8 and a bottom are respectively provided at the upper and lower ends of the silo assembly. Partition 18, the upper end of the silo assembly is installed with the cylinder assembly through the top partition, the lower end is installed with the inner sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com