Production method of fiber sheet material and fiber sheet material produced by adopting method

A production method and fiber technology, applied in the field of fiber board, can solve the problems of long time consumption and low yield, and achieve the effects of short time consumption, smooth surface and strong scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

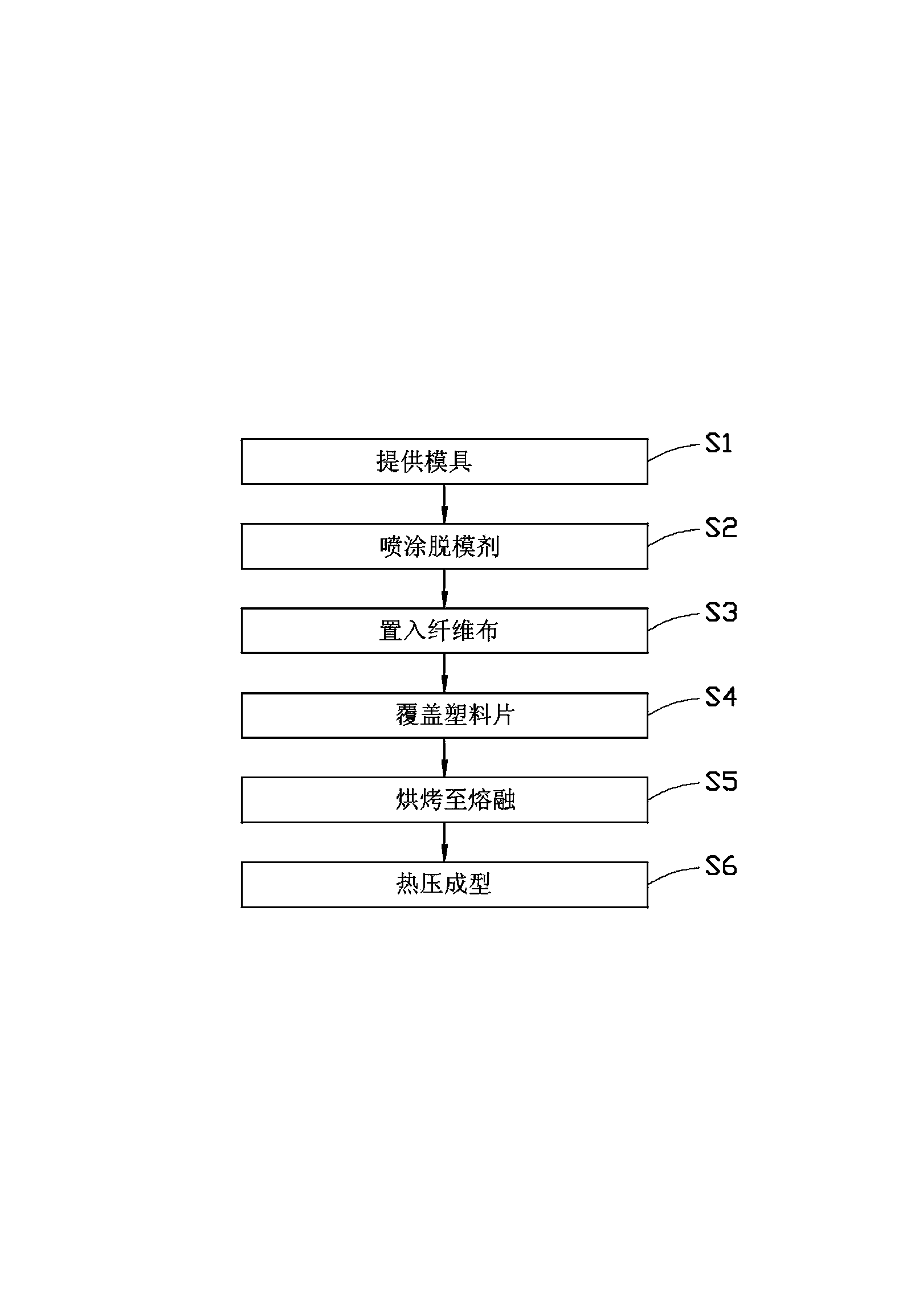

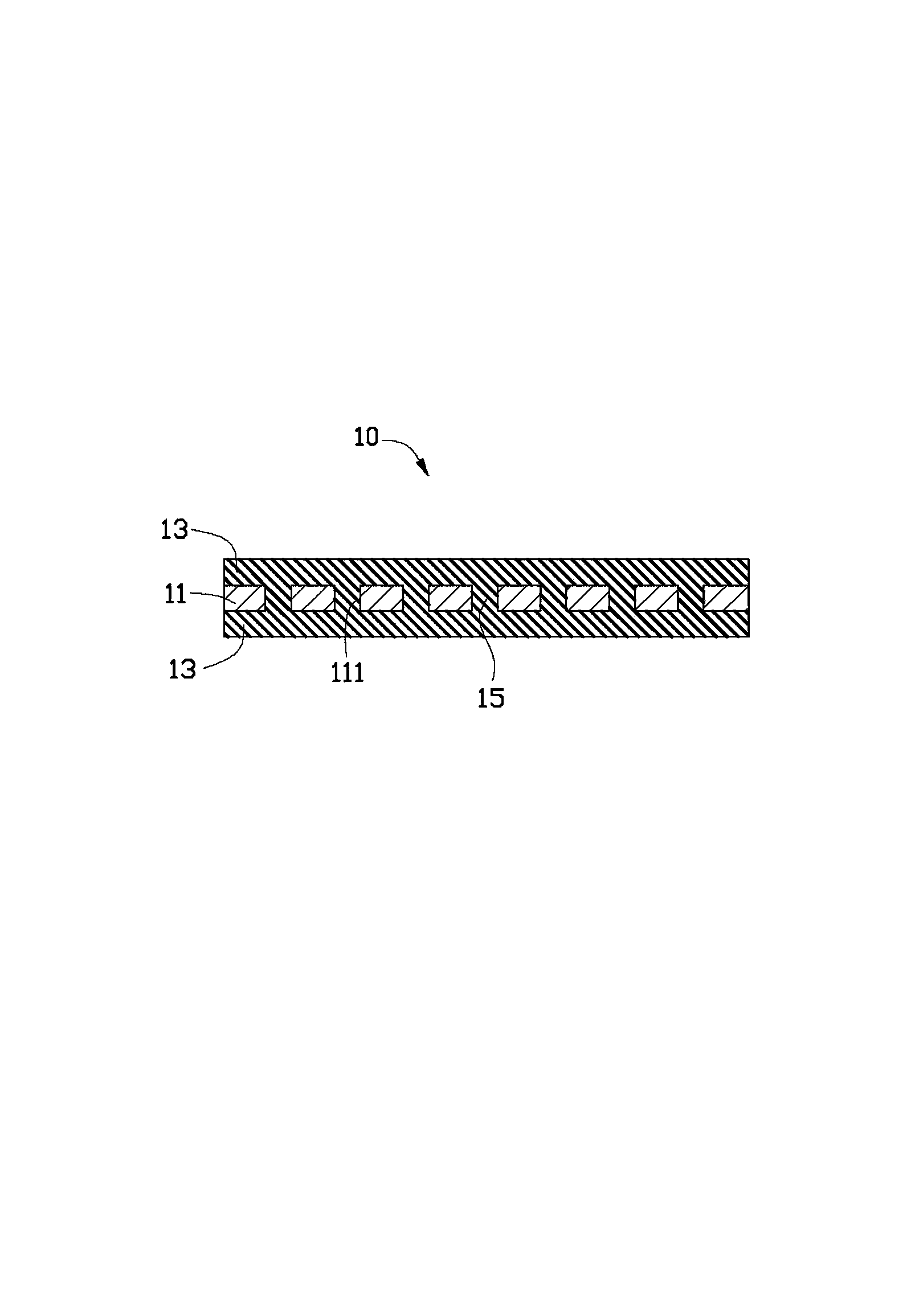

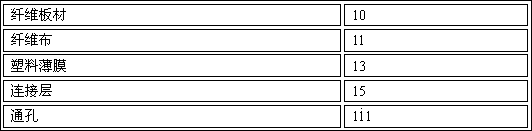

[0017] Please refer to figure 1 and figure 2 , a method for manufacturing a fiberboard according to a preferred embodiment of the present invention, which includes the following steps.

[0018] Step S1: Provide a mold (not shown). The mold cavity (not shown) of the mold has a shape and size matched with a fiber cloth 11 . The fiber cloth 11 has several through holes 111 . The fiber cloth 11 can be made of thermoplastic fibers, such as carbon fibers, glass fibers, or aramid fibers. The fiber cloth 11 has a thickness of 0.1-0.3 mm.

[0019] Step S2: providing a release agent. The release agent is sprayed in the mold cavity of the mold to facilitate demoulding.

[0020] Step S3: After heating the mold until the mold cavity temperature is 200-250° C., insert the fiber cloth 11 into the mold cavity.

[0021] Step S4: Provide a plastic sheet (not shown), the plastic sheet has a shape that matches the fiber cloth 11 . The plastic sheet can be made of thermoplastic polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com