Ship mooring and positioning method

A mooring positioning and anchoring positioning technology, applied in the direction of ships, etc., can solve the problems of the impact of water structures and the impact of ships, and achieve the effect of ensuring safety and preventing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

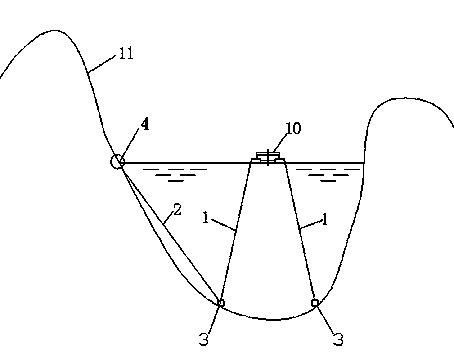

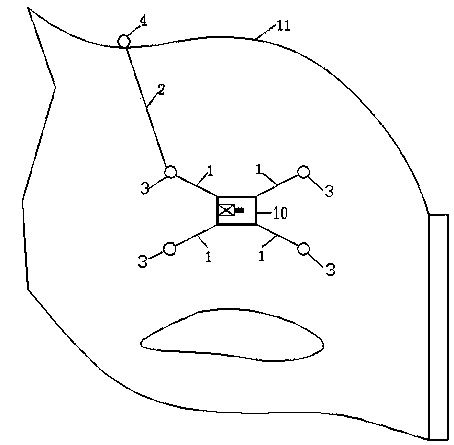

[0018] The method steps of the present invention are illustrated by the following figures.

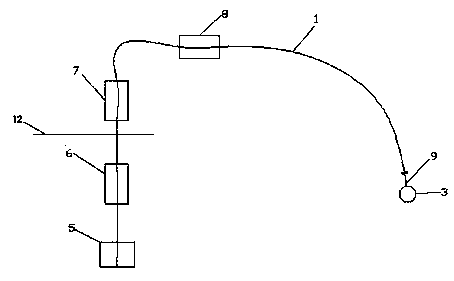

[0019] Such as figure 1 , figure 2 Shown is a schematic diagram of the layout of the ship mooring positioning structure of the present invention. Wire rope 1, 2, anchor 3, shore fixing device 4, winch 5, vertical shaft fairlead 6, vertical fairlead pulley 7, six-roller fairlead 8, anchor chain 9.

[0020] The winch 5 and the vertical shaft fairlead 6 are placed below the hull deck 12 . The winch 5 is fixed in the fore and aft winch compartment of the ship through the base; the vertical shaft fairlead 6 is fixed in the bulkhead in the fore and aft winch compartment through the base; the vertical fairlead pulley 7 and the six-roller fairlead 8 are fixed in the ship through the base on deck 12.

[0021] The steel wire rope 1 passes through the winch 5's own cable arrangement, reaches the vertical shaft fairlead 6, goes vertically upward to the vertical fairlead pulley 7 of the main d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com