Bottle arranging machine

A technology of a bottle unscrambler and a fan, applied in the field of bottle unscramblers, can solve the problems of reducing production efficiency, affecting the probability of plastic bottles entering the working position, and poor connection between bottles and filling lines, and achieving the effect of improving bottle unscrambling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

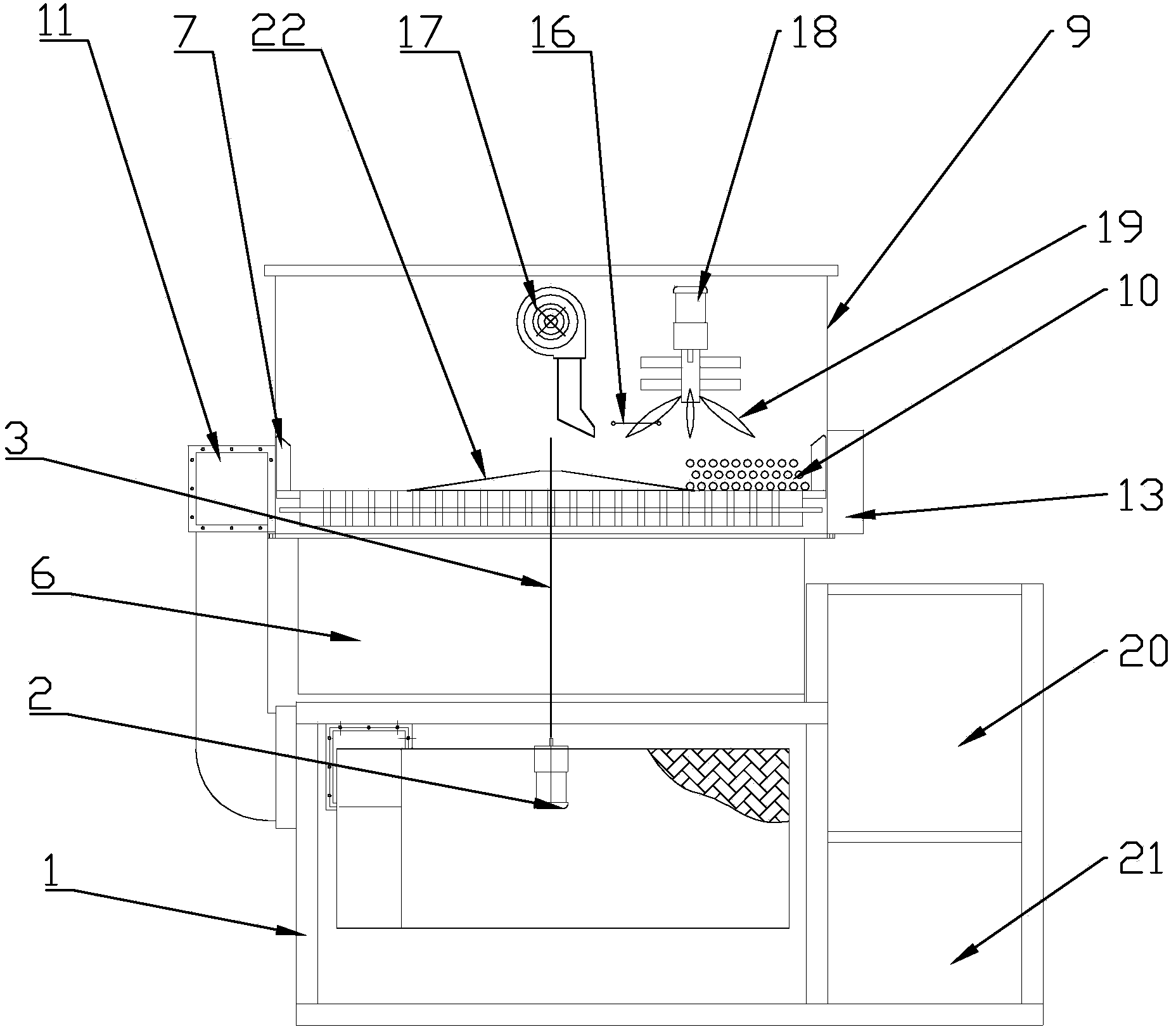

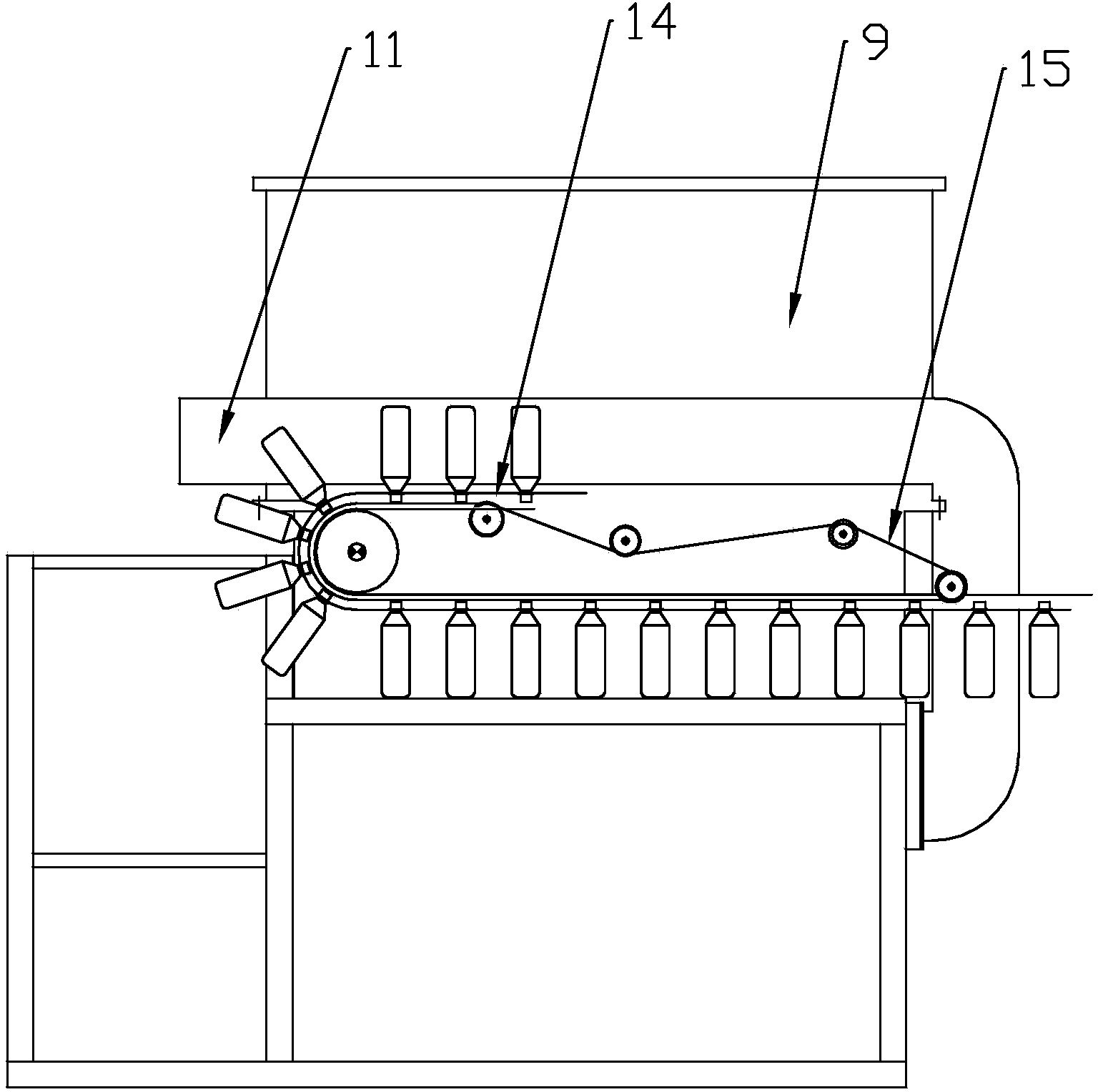

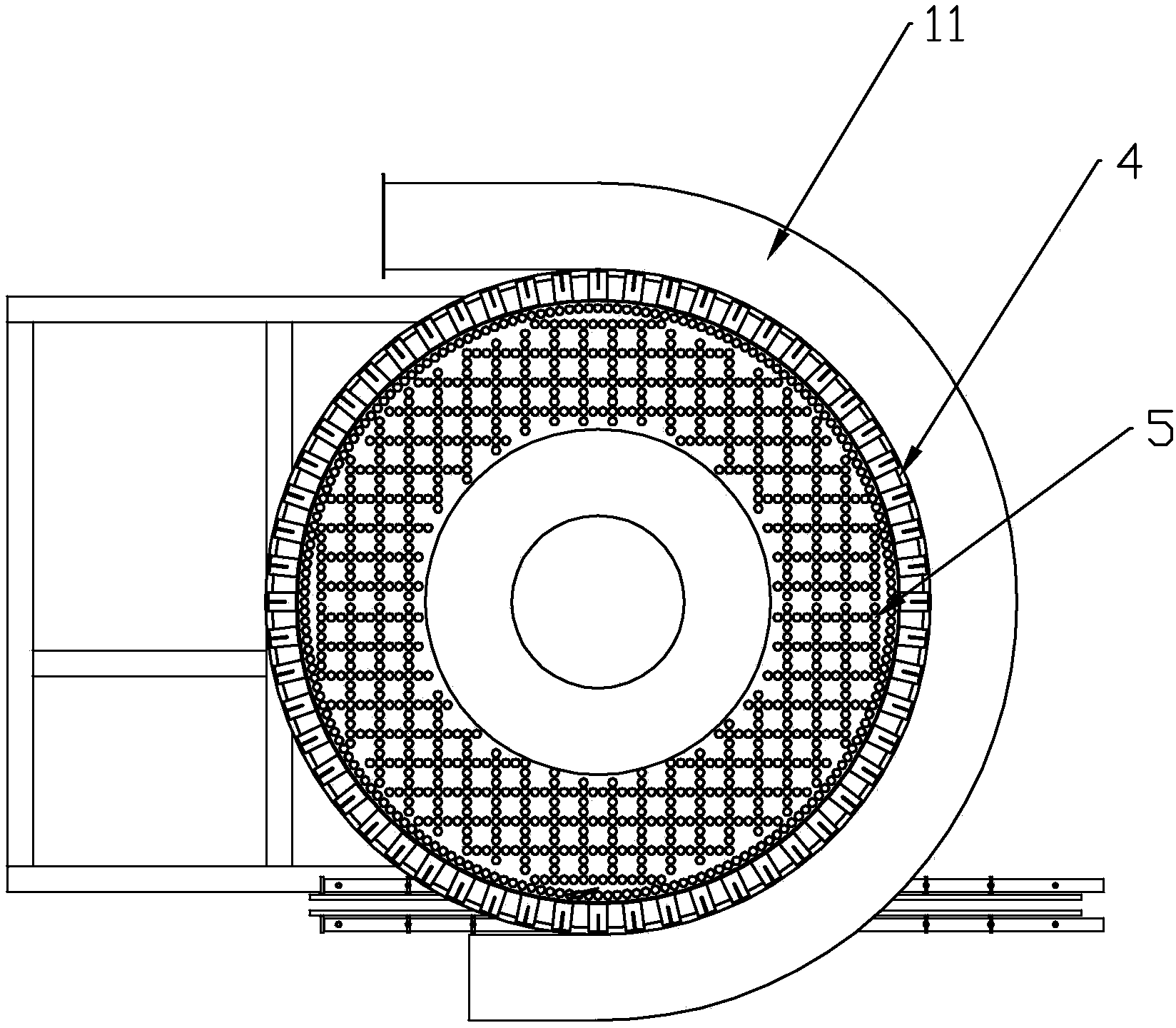

[0032] As shown in 1-3, a bottle unscrambler includes a frame 1, a fan on the frame 1, a motor 2, and the fan communicates with the upper air chamber 6 through the pipeline I, and the upper part of the air chamber 6 is provided with a The motor 2 is connected to the turntable 4 through the main shaft 3. The middle part of the turntable 4 is provided with a conical protrusion 22 coaxial with the turntable 4. The turntable 4 is provided with several vertically upward guiding air ducts 5, and several guiding air ducts 5 are arranged alternately. composed as image 3 The several frame shapes shown can also form several circles, triangles, rhombuses, polygons or irregular figures depending on the type of bottle 50 as the case may be. The blower fan communicates with the guide air duct 5 through the air chamber 6, and the edge of the turntable 4 is provided with several such as Figure 6 The limiting mechanism shown, the limiting mechanism includes a bottle body baffle 7, a bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com