Stretched membrane feeding tension control device

A tension control and stretch film technology, which can be used in transportation and packaging, strip winding, thin material handling, etc., and can solve problems such as troublesome adjustment and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

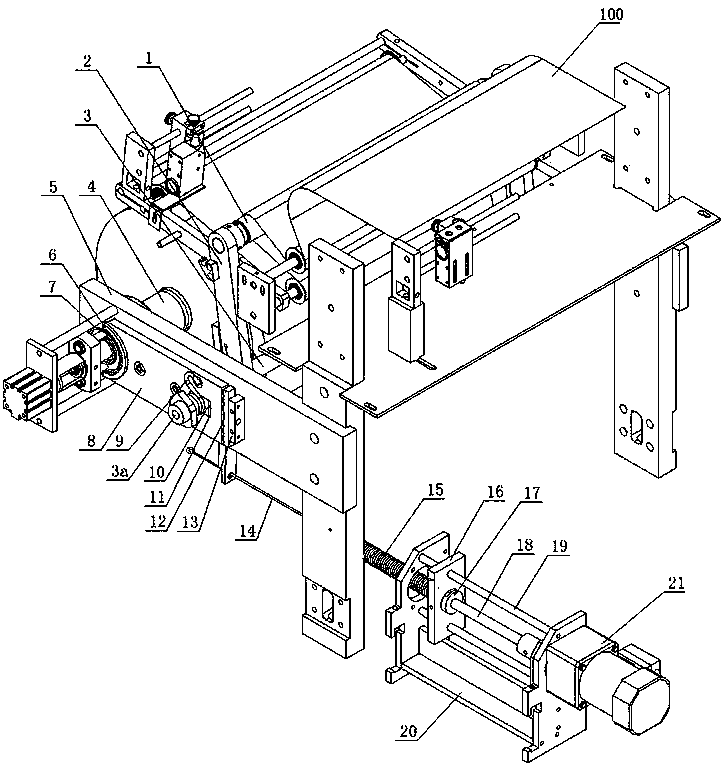

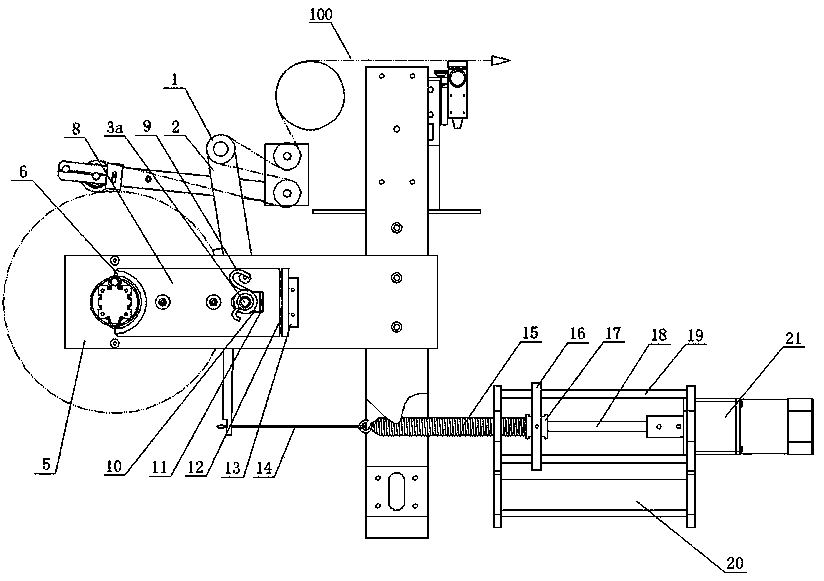

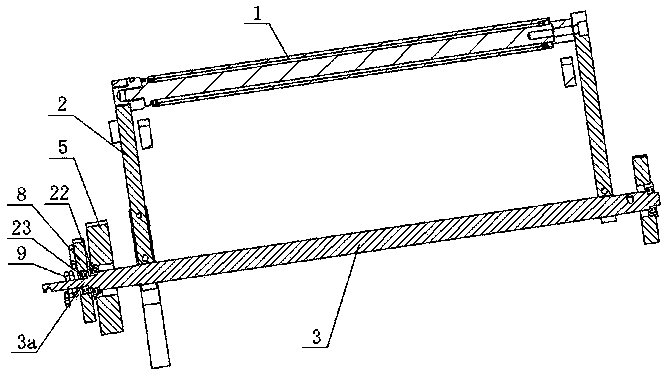

[0013] As shown in the figure, the stretched film feeding tension control device of the present invention includes a mounting frame 5 and a stretched film unwinding shaft 4 that is rotated on the mounting frame 5, and the film 100 on the stretching film unwinding shaft 4 is wound through several Send out after the guide roller, which includes a tension control roller 1, the tension control roller 1 is installed on the upper swing end of the pendulum rod 2, the pendulum rod 2 is fixed on the eccentric shaft 3, and the eccentric shaft 3 rotates through the bearing 22 Located on the mounting frame 5, after the eccentric shaft 3 rotates, it is reset by the torsion spring 9 located at its shaft end or the extension spring adjusting part located at the lower end of the swing rod 2 is reset. The outer side of the mounting frame 5 is provided with a The sliding seat 8 that slides left and right, one end of the sliding seat 8 is provided with a brake pad 6 and the brake wheel 7 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com