TPU (thermoplastic polyurethane) film with high hydrolytic stability and preparation method of TPU film

A technology of hydrolytic stability and film, which is applied in the field of TPU film with high hydrolytic stability and its preparation, can solve problems such as insufficient hydrolytic stability, and achieve the effects of improved mechanical property retention rate, improved hydrolytic stability, and high hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

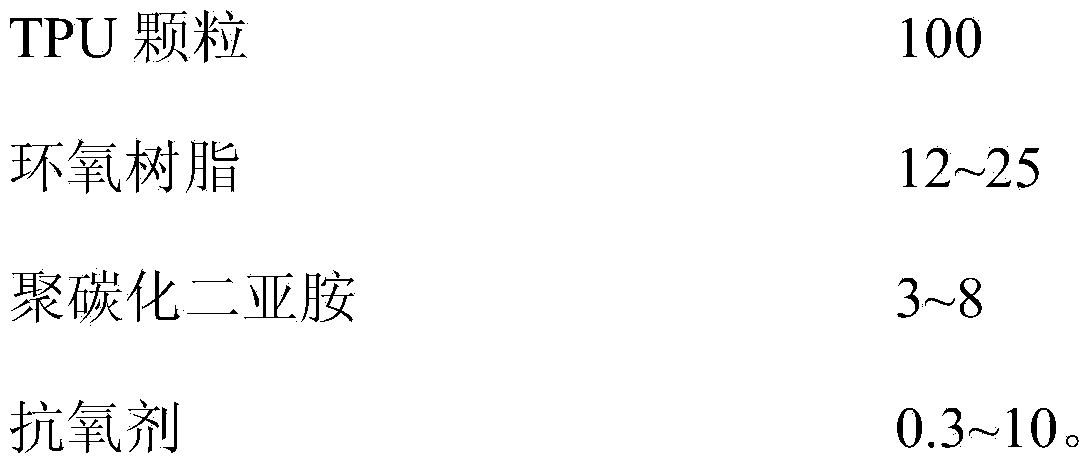

[0035] A kind of TPU film with high hydrolysis stability, described TPU film comprises following composition by weight part:

[0036]

[0037] 1) Pre-drying the ingredients; the drying temperature is 80°C, and the drying time is 3h;

[0038] 2) Mix the ingredients according to the formula amount, and extrude at 180° C. to obtain a TPU film with high hydrolysis stability.

Embodiment 2

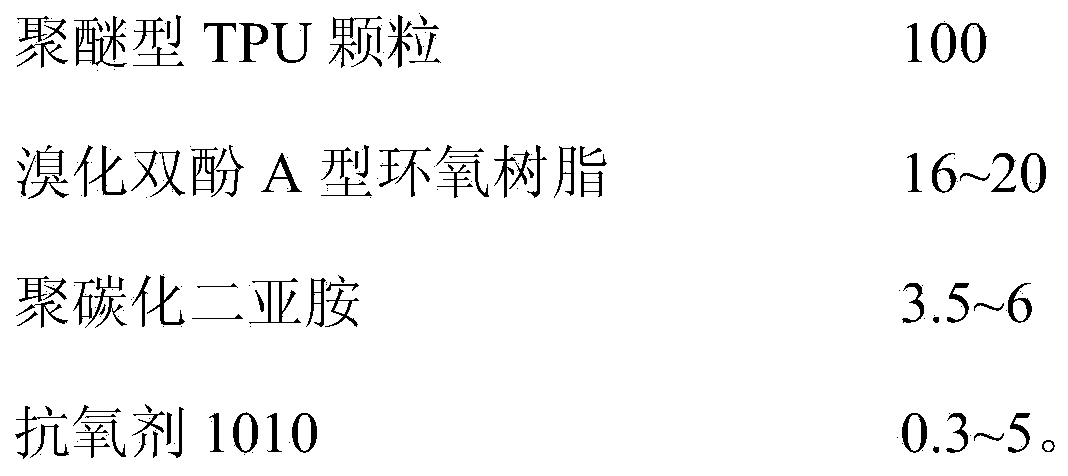

[0040] A kind of TPU film with high hydrolysis stability, described TPU film comprises following composition by weight part:

[0041]

[0042] 1) Pre-drying the ingredients; the drying temperature is 90° C., and the drying time is 2 hours;

[0043] 2) Mix the ingredients according to the formulation amount, and extrude at 200° C. to obtain a TPU film with high hydrolysis stability. Example 3

Embodiment 3

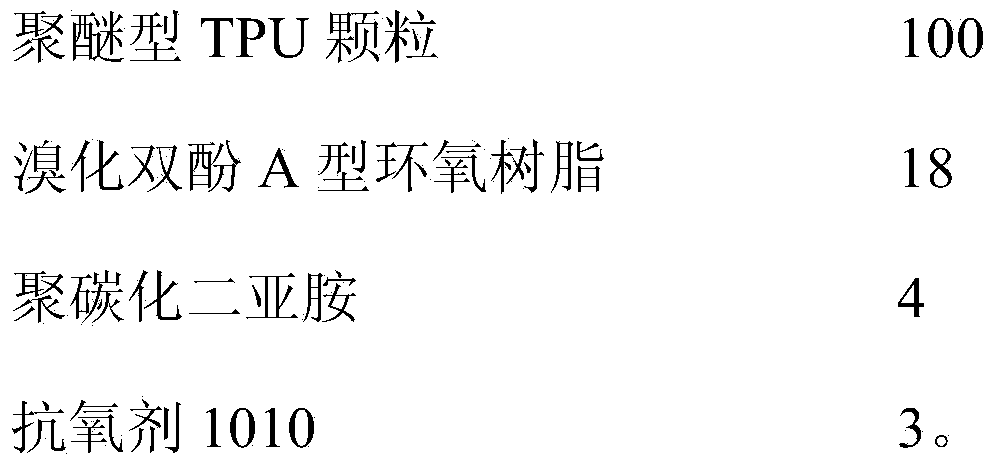

[0044] A kind of TPU film with high hydrolysis stability, described TPU film comprises following composition by weight part:

[0045]

[0046] 1) Pre-drying the ingredients; the drying temperature is 82°C, and the drying time is 2.8h;

[0047] 2) Mix the ingredients according to the formula amount, and extrude at 192° C. to obtain a TPU film with high hydrolysis stability. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com