Wire splitting pre-deformation assembly of strand twisting device

A pre-deformation and wire-dividing technology, which is applied in auxiliary devices for rope making, textiles and papermaking, textile cables, etc., can solve the problems of large equipment occupation area, low production efficiency, poor safety performance, etc., and achieve small footprint, The effect of high work efficiency and stable work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

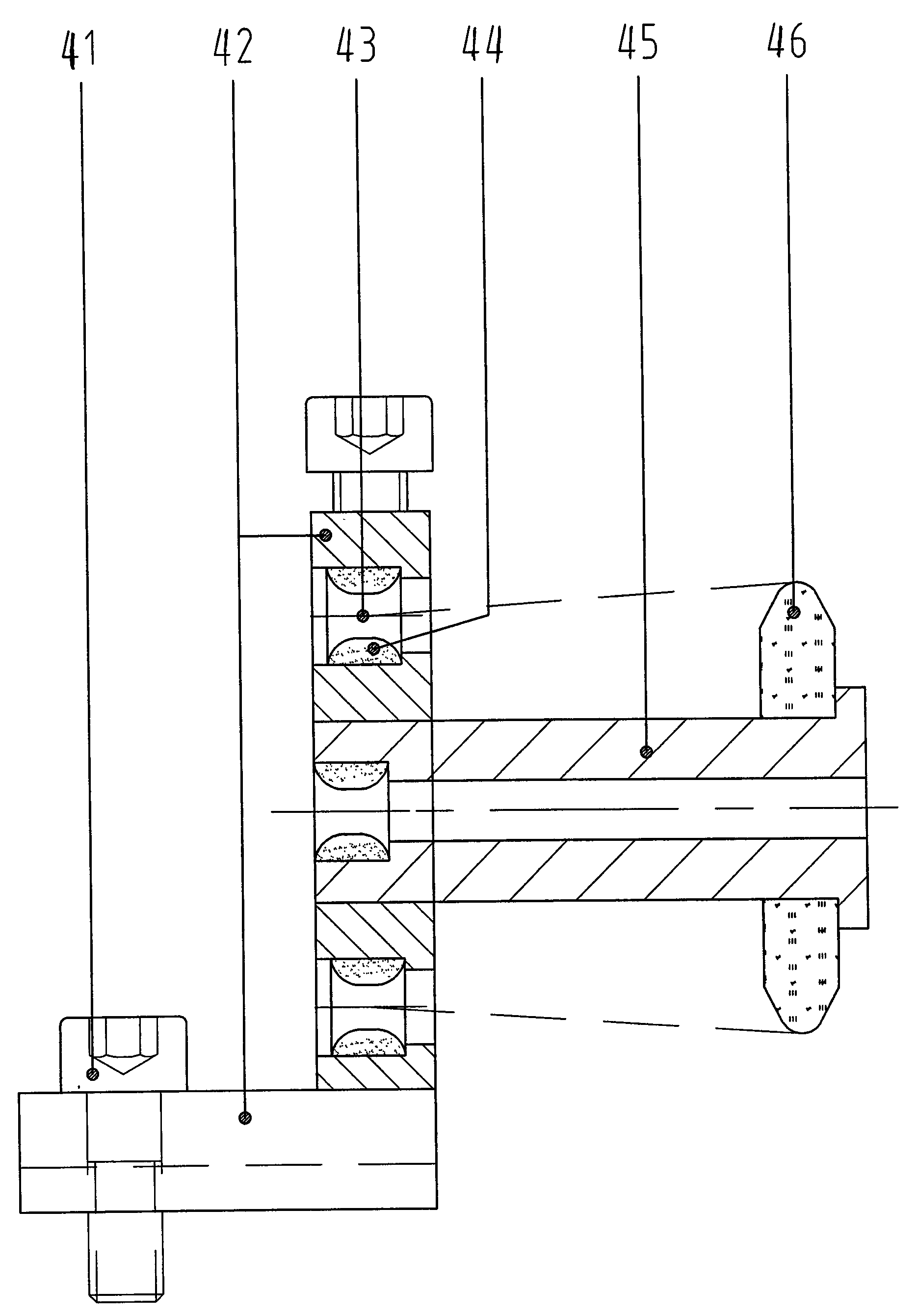

[0010] refer to image 3 As can be seen, the branching pre-deformation assembly 32 of the (two-way) twisting device of the present invention comprises a branching support 42, on which a line entry mold 44 is housed, and in the line entry mold 44 (and the line branching support) Adjusting rod 45 is housed on the middle part of 42), and deformation ring 46 is housed on the outer end of this adjusting rod 45. Wherein, there are several die holes 43 (corresponding to the number of the wire-releasing assemblies 23) on the described line-entry mold 44, and the described wire-dividing support 42 (by screw 41) is contained on the cradle 21 (such as figure 2 shown).

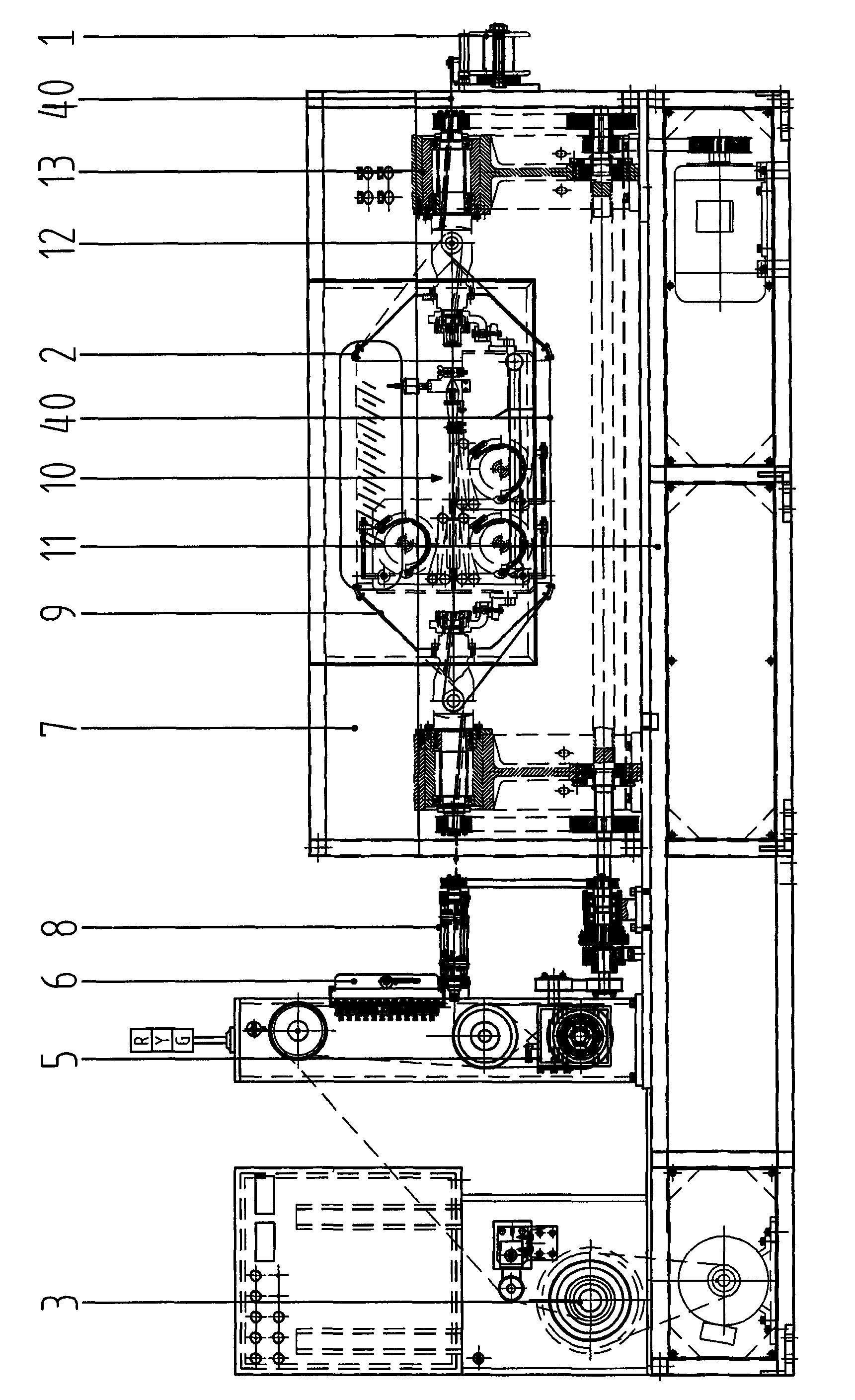

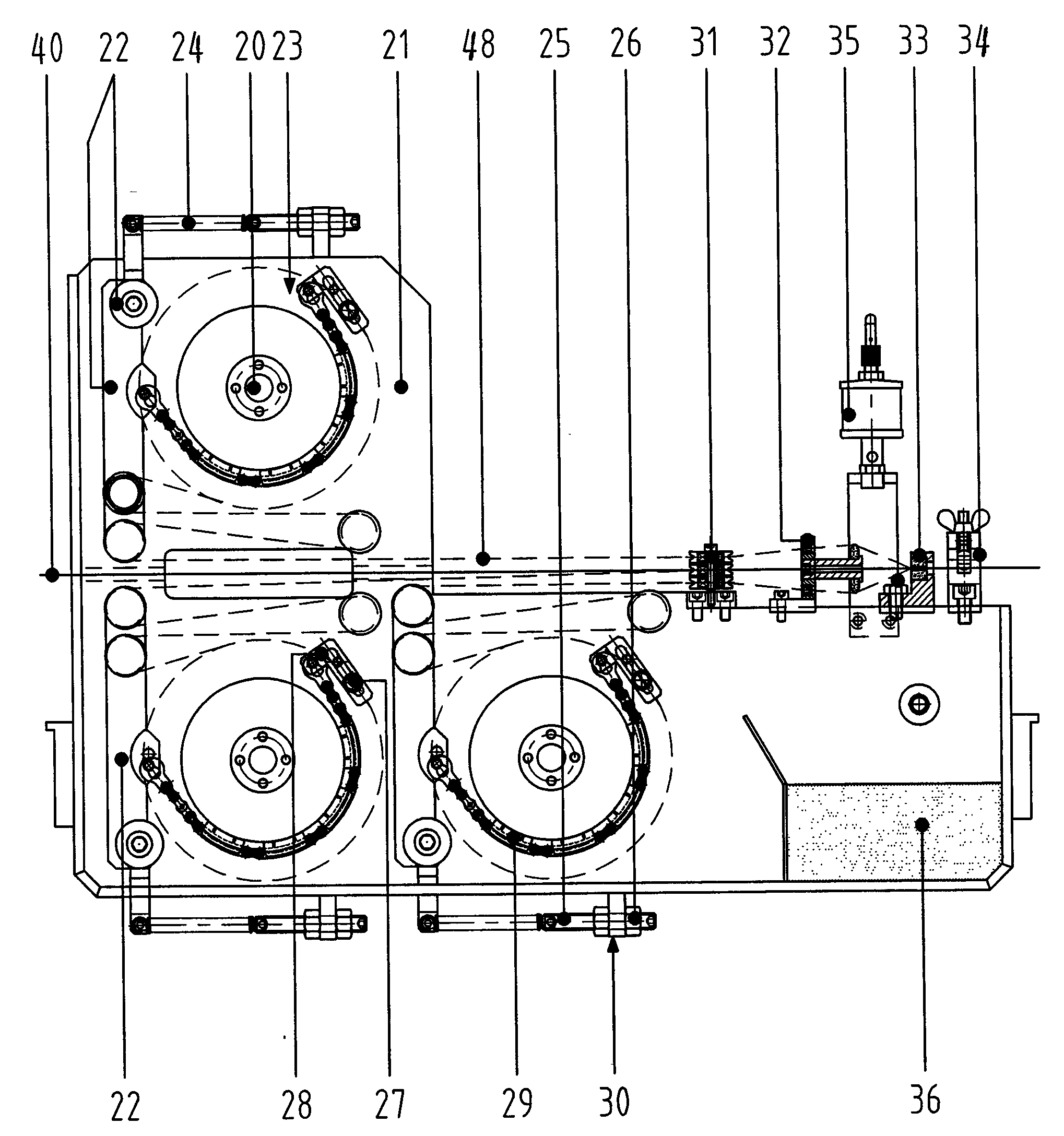

[0011] refer to figure 1 , figure 2 It can be seen that the (two-way type) twisting device used in the present invention also includes a main frame 11 and a rotary bearing mechanism 13 (two pieces of left and right, each containing a rotating motor, a synchronous transmission assembly, etc.), on the main frame 11 Fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com