Two-way strand twisting device and center steel wire pay-off method

A two-way, steel wire technology, applied in the field of stranding devices, can solve the problems of large equipment occupation area, low production efficiency, high working noise, etc., and achieve the effect of small occupation area, improved work efficiency and stable work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

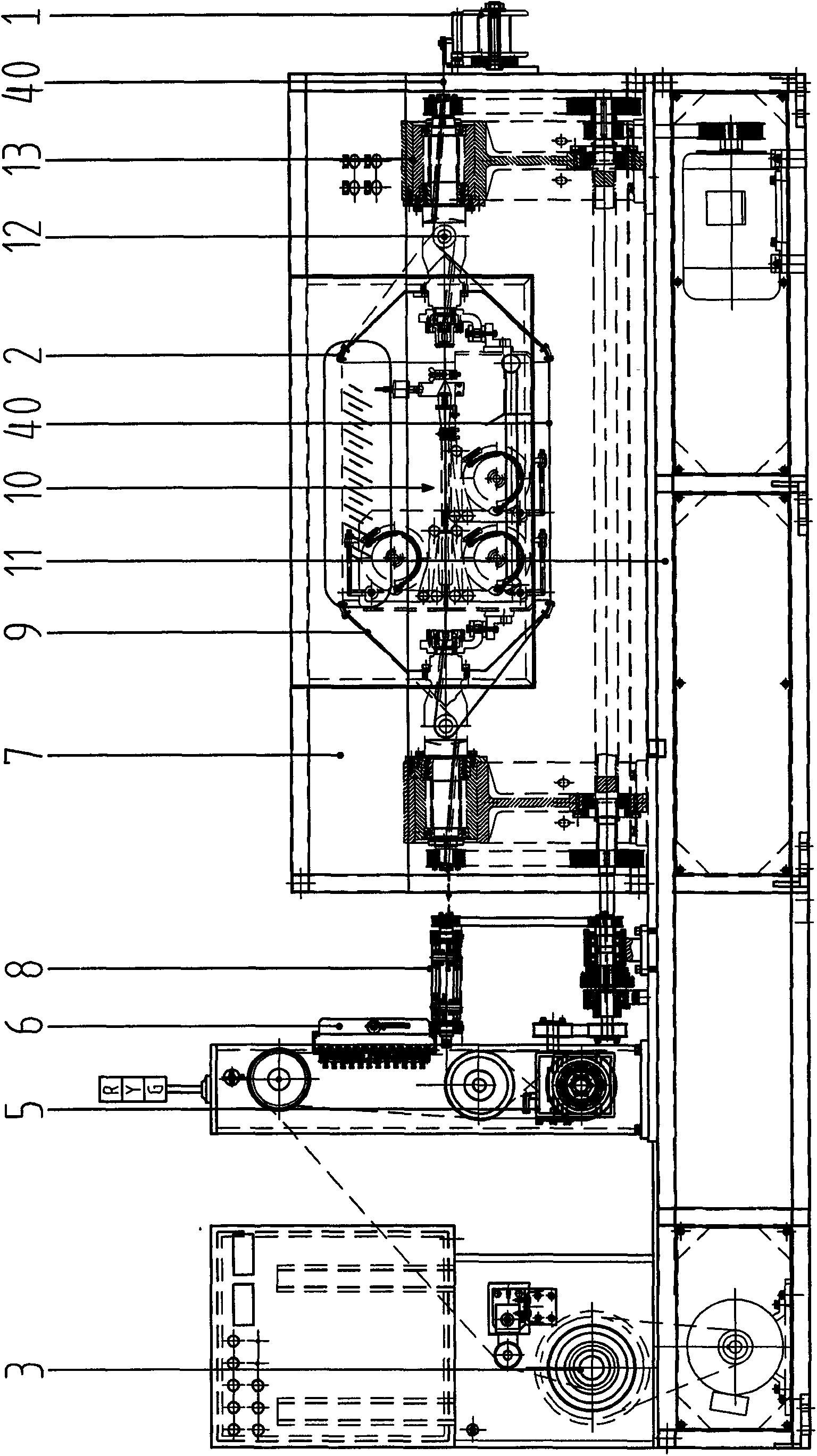

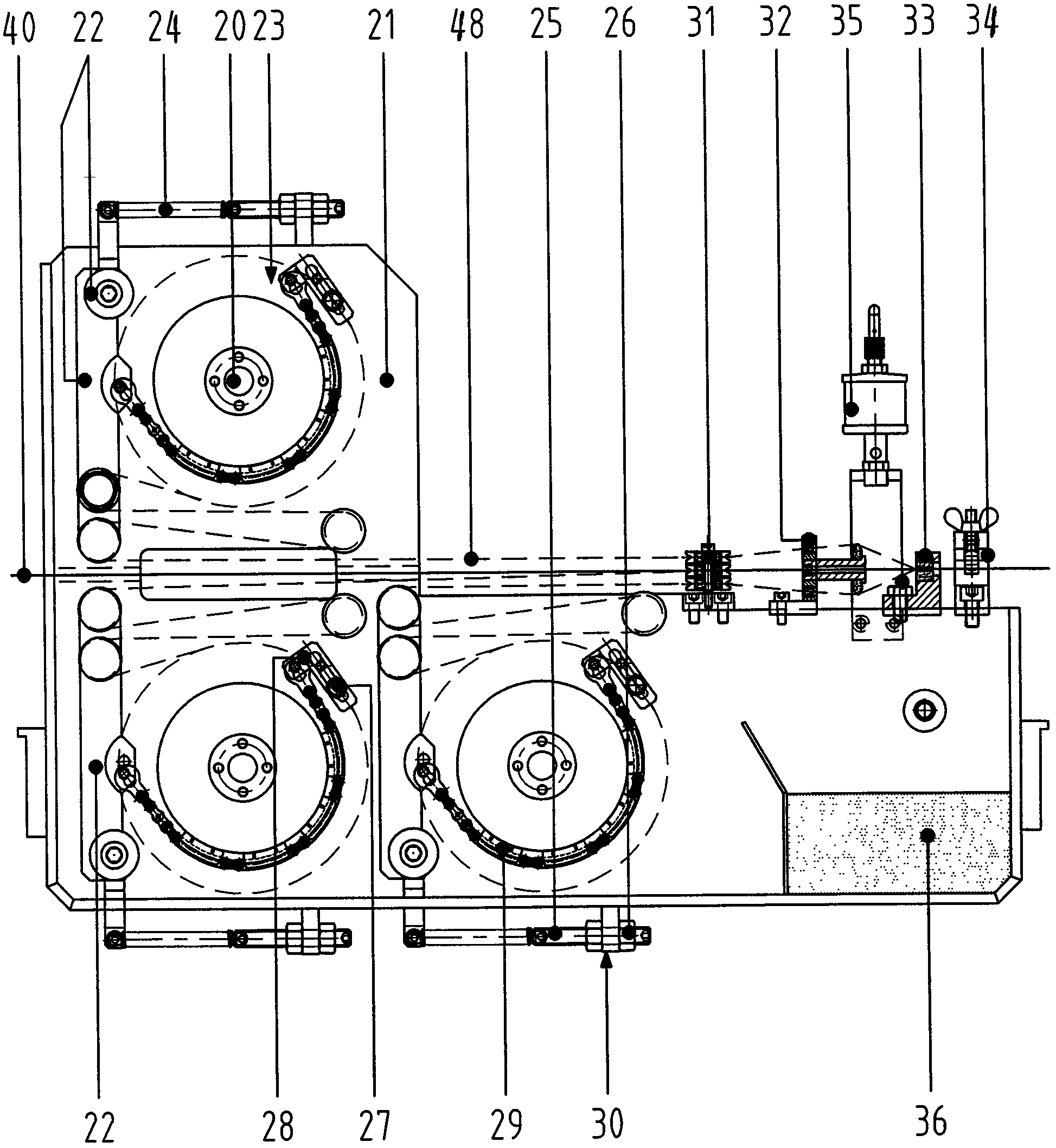

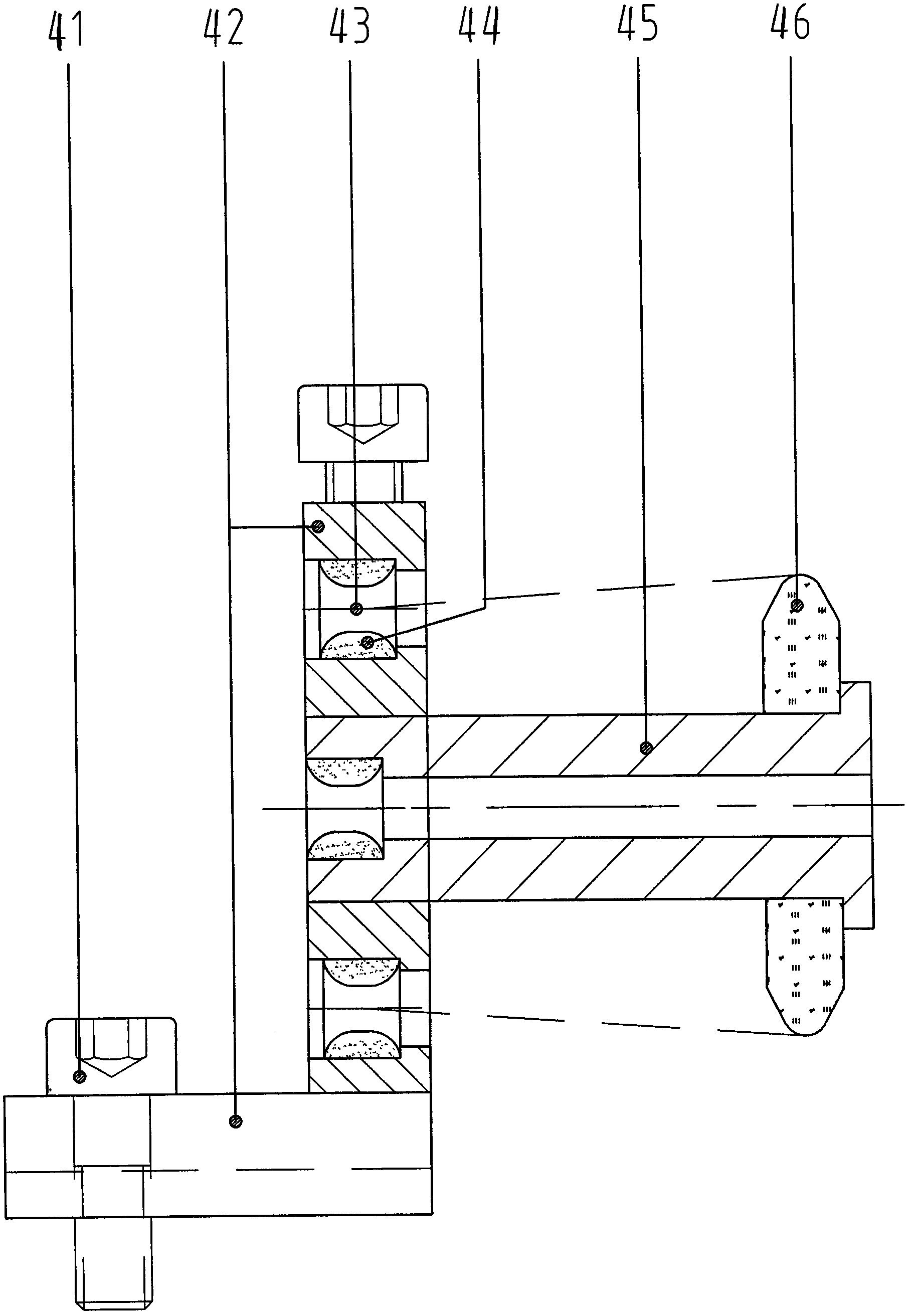

[0011] refer to figure 1 , figure 2 It can be seen that the two-way twisting device of the present invention comprises a main frame 11 and a rotating bearing mechanism 13 (being left and right, each containing a rotating motor, a synchronous transmission assembly, etc.), on the main frame 11, and on the rotating bearing Flywheels 9 are respectively installed between the mechanisms (for left and right, each containing a flywheel shaft), on the main frame 11, and between the flywheels and the flywheels, a cradle 21 is installed. Pay-off assemblies 23 (several pieces) are housed on the blue frame 21, and on the described cradle 21, and at the side of the pay-off assembly 23 (for the outermost), the wire-distributing guide wheels 31, wire-distributing wheels, Pre-deformation assembly 32, wire collecting die 33 (and wire pressing shoe assembly 34). Line passing slide block 2 (hard wear-resistant type) is all housed on (up and down) both side edges of described flywheel 9.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com