A Design Method of Reinforced Floor Chords for Pipe Truss Structures

A design method and technology of pipe truss, applied in the direction of building structure, construction, etc., can solve the problems of difficult to meet the architectural shape, the reinforcement effect is not obvious, and the bending rigidity is large, so as to improve the distribution and avoid the sharp increase of the bending rigidity of the section. The effect of large and reasonable structural force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

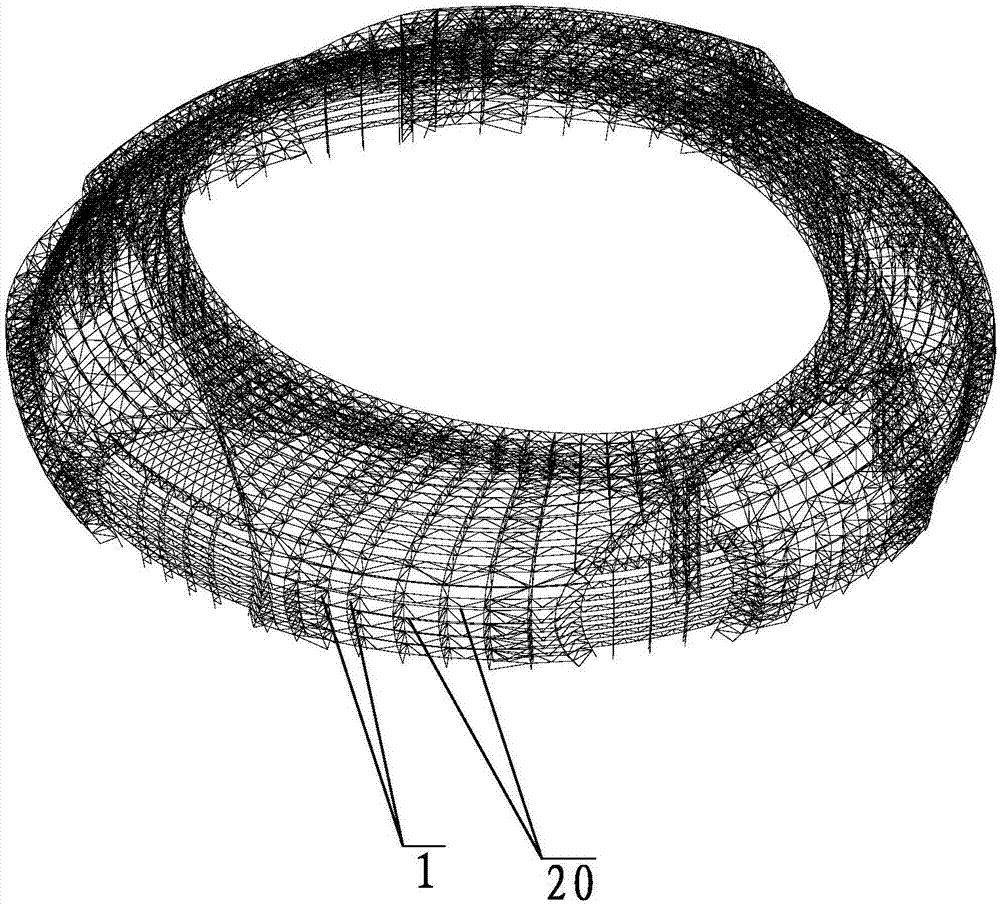

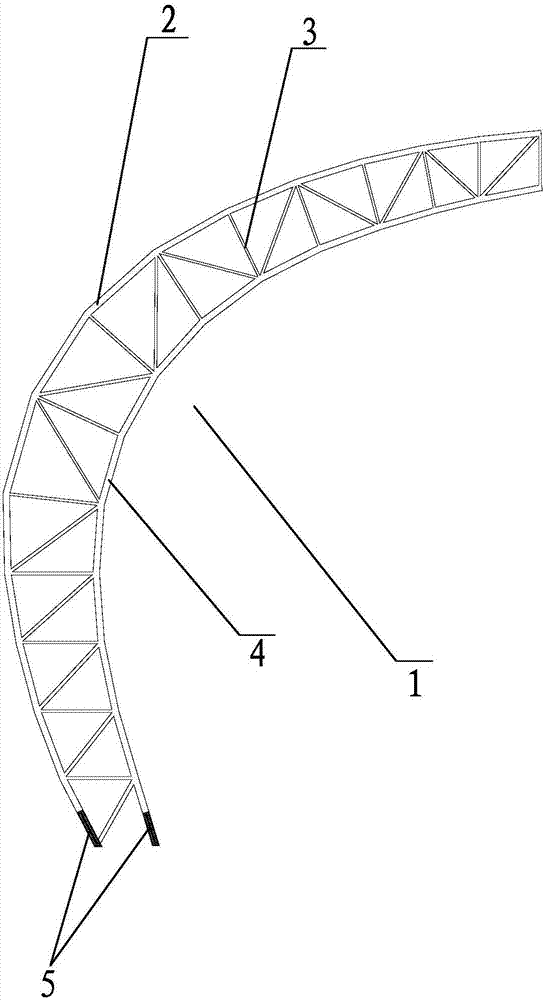

[0020] combine figure 1 As shown, the typical space tube truss structure applicable to the present invention is composed of a plurality of single tube trusses 1, ring trusses 20 and attached rods. combine figure 2 As shown, the single-tube truss 1 is composed of an upper chord 2, a web 3, and a lower chord 4, and the reinforced ground chord 5 of the present invention is installed at the contact between the single-tube truss 1 and the ground.

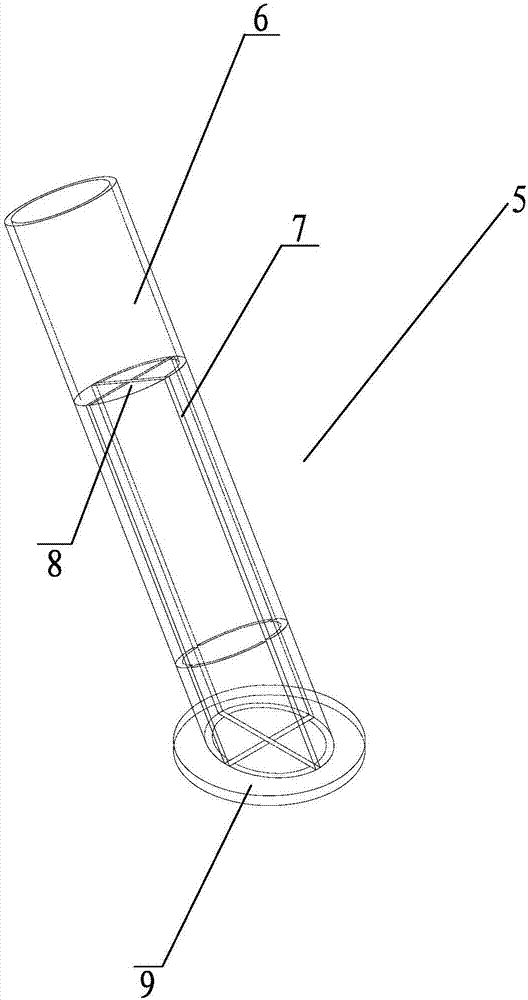

[0021] combine image 3 As shown, a reinforced floor chord 5 of a pipe truss 1 structure, which includes a reinforcement section 6, four slots 7 are opened on the reinforcement section 6, and a cross stiffener 8 is welded in the notch of the floor chord reinforcement section 6; The welding method of the reinforced landing chord is penetration welding, and the reinforced landing chord 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com