Forging machine axle seat

A forging press and shaft seat technology, applied in the field of forging press accessories, can solve the problems of difficult processing, inconvenient installation and maintenance, etc., and achieve the effect of low difficulty, convenient processing and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

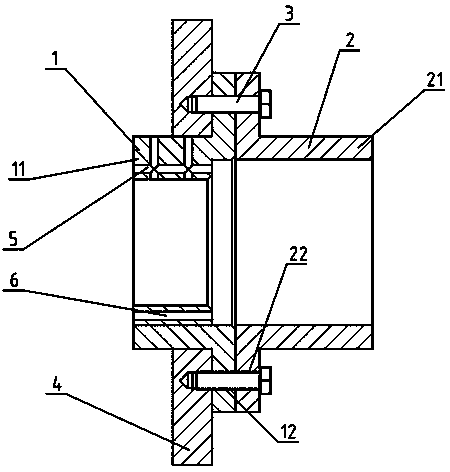

[0013] As shown in the figure, a shaft seat of a forging press includes a first seat body 1, the first seat body 1 is an annular flange, and extends to one side to form a first boss 11, the first seat body 1 The flange on the outside of the boss 11 is uniformly provided with first holes 12, and also includes a second seat 2, which is also a ring-shaped flange, and extends to one side to form a second protrusion. A platform 21, a second hole 22 corresponding to the first hole 12 is provided on the flange on the outer side of the second boss 21, and the fixing bolt 3 passes through the first hole 12 and the second hole 22 to fix the first seat body 1 and the second seat body 2 on the base 4 .

[0014] The first boss 11 is provided with an oil inlet hole 5 and an oil outlet hole 6 .

no. 2 example

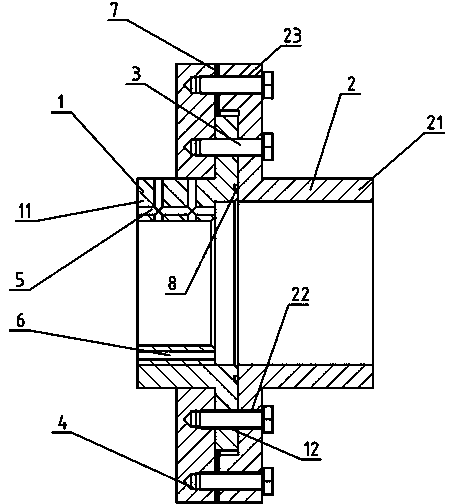

[0016] The second embodiment is based on the first embodiment, and the outside of the second hole 22 is evenly provided with a third hole 23, and the fixing bolt 3 passes through the third hole 23 to fix the second seat body 2 on base 4.

[0017] An adjustment pad 7 is provided at the joint between the second seat body 2 and the base 4 .

[0018] A sealing ring 8 is provided at the joint between the first base body 1 and the second base body 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com