Optimized layout method for mirror field of linear Fresnel concentration system

A technology of linear Fresnel and concentrating system, which is applied in the field of optimal arrangement of shadowless mirror fields, and can solve the problems of shadow effect of linear Fresnel concentrating system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

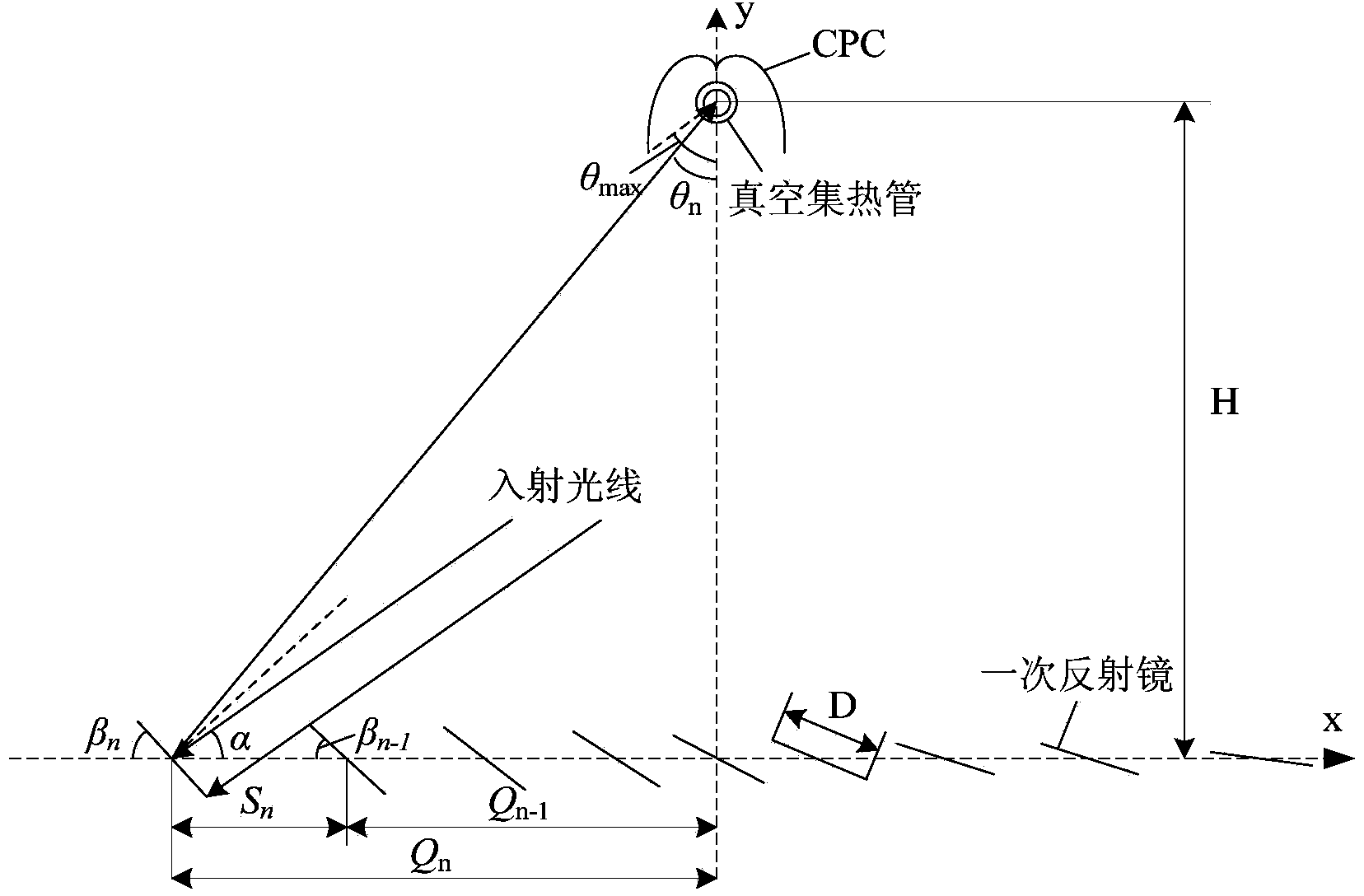

[0027] See figure 1 , The layout principle of the mirror field of the linear Fresnel concentrating system. The maximum accepted half angle of CPC is θ max ;The receiver is placed at the height H from the plane where the mirror is located; the width of the mirror is D; the distance between the center of the nth mirror and the center of the mirror field is Q n , the angle between it and the horizontal plane is β n (tilt angle); the distance between adjacent mirrors is S n ; The incident angle of sunlight is α(α ); the incident angle of reflected light is θ n .

[0028] A method for optimizing the arrangement of the mirror field of a linear Fresnel type concentrating system, the main feature of which is to include the following steps:

[0029] (1) Select the CPC and determine the maximum acceptance half-angle θ of the CPC max and the width D of the mirror;

[0030] (2) Set the sunlight incident angle α( ) and mirror row number N;

[0031] (3) given CPC height H;

[0...

Embodiment 2

[0048] Embodiment 2: a method for optimizing the layout of the mirror field of a linear Fresnel type concentrating system, setting the sunlight incident angle α to be 60° and 30° respectively, that is, the shadow-free working time t of the system is 4h and 8h respectively, the steps And other parameters are with embodiment 1. The arrangement spacing of the 21 columns of reflectors for the shadowless working time of the system for 4h and 8h are shown in Table 2 and Table 3 respectively:

[0049] Table 2 The mirror field layout of the system with shadowless working time of 4h

[0050]

[0051] Table 3 The mirror field layout of the system with a shadow-free working time of 8 hours

[0052]

Embodiment 3

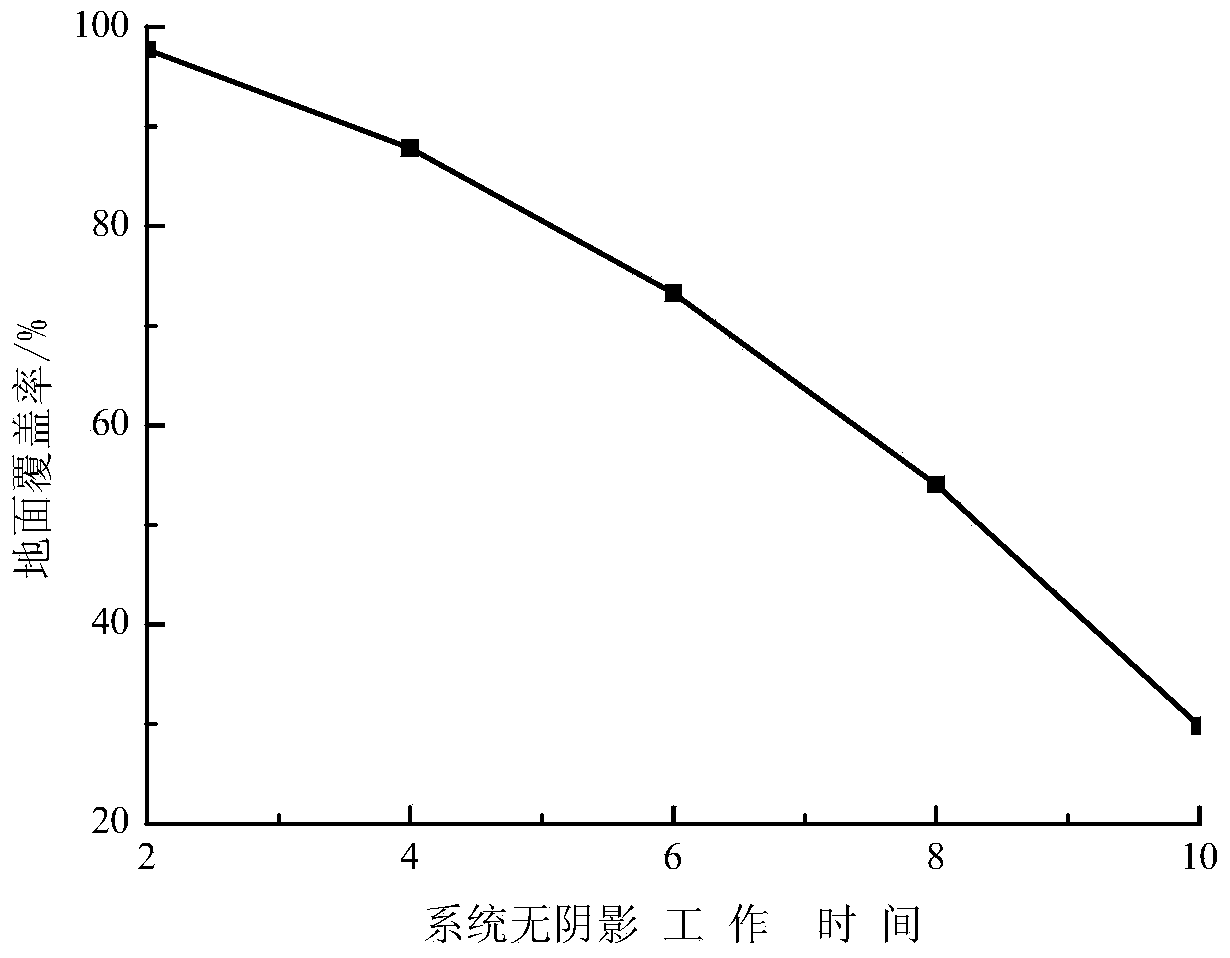

[0053] Embodiment 3: A method for optimizing the arrangement of the mirror field of a linear Fresnel type concentrator system. If the solar incident angle α is selected to have different values, it corresponds to different arrangement spacings, and different arrangement spacings correspond to different ground coverage. The relationship between the shadow-free working time of the system and the ground coverage is as follows: figure 2 shown.

[0054] The optimal layout method of the mirror field of the linear Fresnel type concentrating system, the shadowless working time t of the system is selected as 6h by optimizing the ground coverage (the system without shadows corresponding to the sunlight incident angle α=45° working hours), and the ground coverage rate is 73.28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com