A fixed structure of heat absorber tube panel

A technology of heat absorber tube panel and fixed structure is applied in the field of heat absorber tube panel structure and fixed structure. Avoid the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

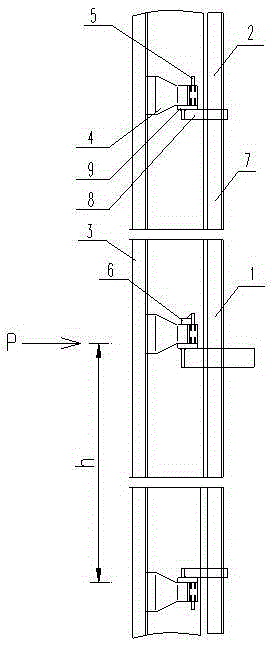

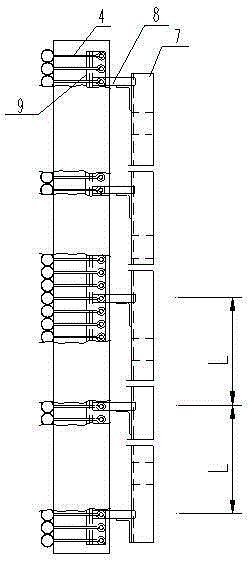

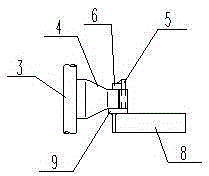

[0023] Such as figure 1 , 2 As shown, a tube panel fixing structure of a heat absorber includes a heated tube 3 forming the tube panel body, a rigid frame 7 supporting the tube panel, a fixed tube clamp set 1 and a sliding tube clamp set 2 . In the specific implementation process, the tube panel is composed of a plurality of light tube heating tubes closely arranged, and tube clamps are set on each heating tube, and the tube clamps at the same horizontal position form a tube clamp group. The fixed tube clamp group is set in the middle of the vertical direction of the tube panel, and the tube panel is fixed by setting blocks; the sliding tube clamp group is not provided with blocks to realize the free expansion of the tube, and the sliding tube clamp group is used to fix the tube panel. The location of the clip group is the zero point of expansion. A row is set up and down along the tube panel at intervals of h according to the height of the tube panel. group) are welded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com