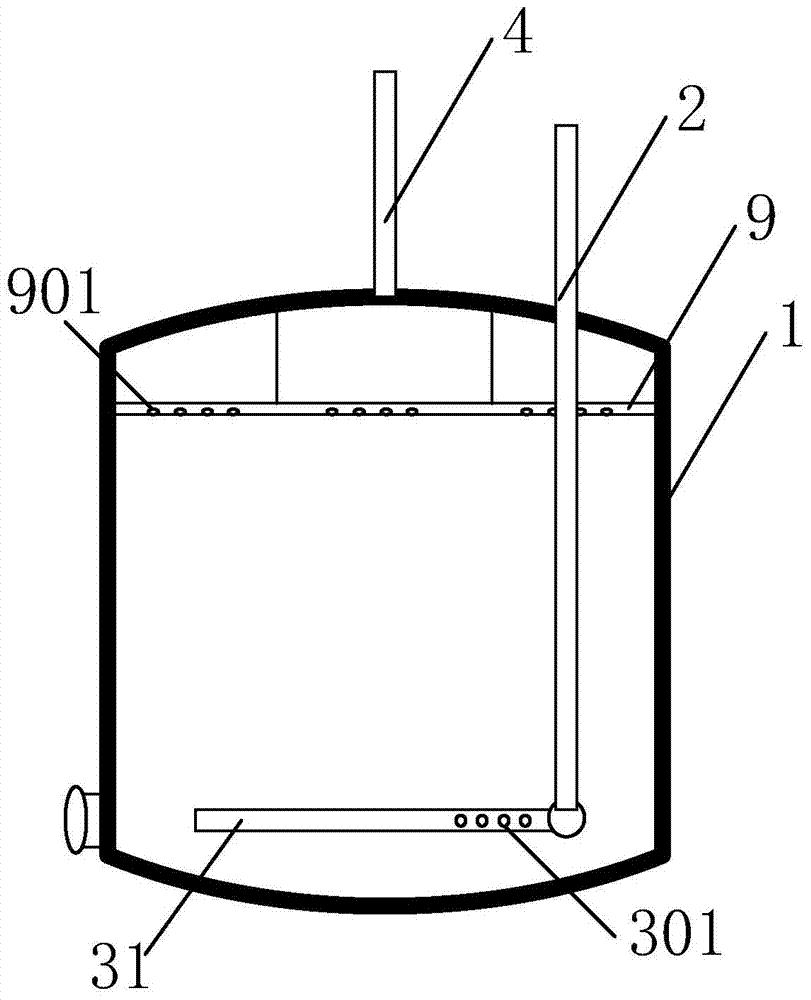

Environment-friendly steam energy hot water production system

A production system and environment-friendly technology, which is applied in the field of environment-friendly steam energy hot water production systems to maximize conversion efficiency, avoid air pollution, and reduce scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

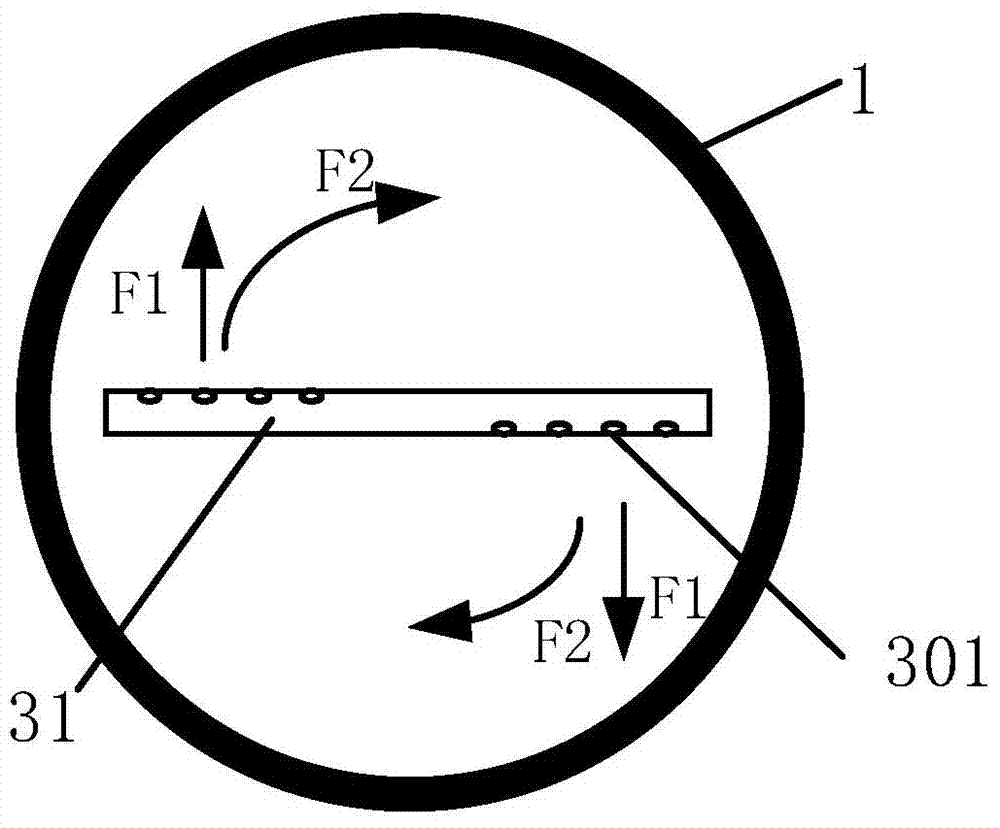

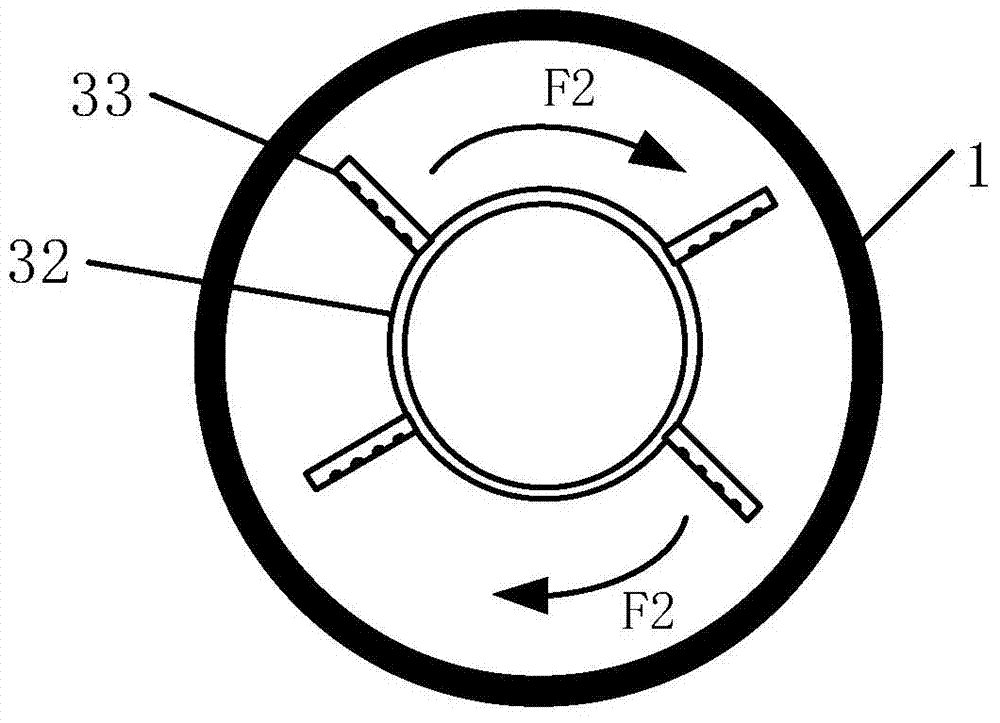

Method used

Image

Examples

Embodiment approach

[0071] As another preferred embodiment, the hot water conversion production process further includes: detecting and / or purifying the cold water input into the heating tank and the hot water output from the heating tank. Specifically, the water inlet pipe 4 and the water outlet pipe 5 of the heating tank 1 are respectively connected to the first and second water quality purification devices 602, and / or the water inlet pipe 4 and the water outlet pipe 5 of the heating tank 1 are also respectively connected to There are first and second water quality monitoring devices 702 .

[0072] As a second optional implementation, the water inlet pipe 4 and the water outlet pipe 5 of the heating tank 1 are respectively connected with a first water quality purification device 601 and a second water quality purification device 602, and the water inlet pipe of the heating tank 1 4 and the water outlet pipe 5 are respectively provided with a bypass water inlet pipe 401 and a bypass water outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com