Laser vibration displacement sensor and measuring method thereof

A technology of displacement sensor and measurement method, which is applied in the field of precision measurement, and can solve the problems of reducing exposure time, low measurement accuracy, and low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

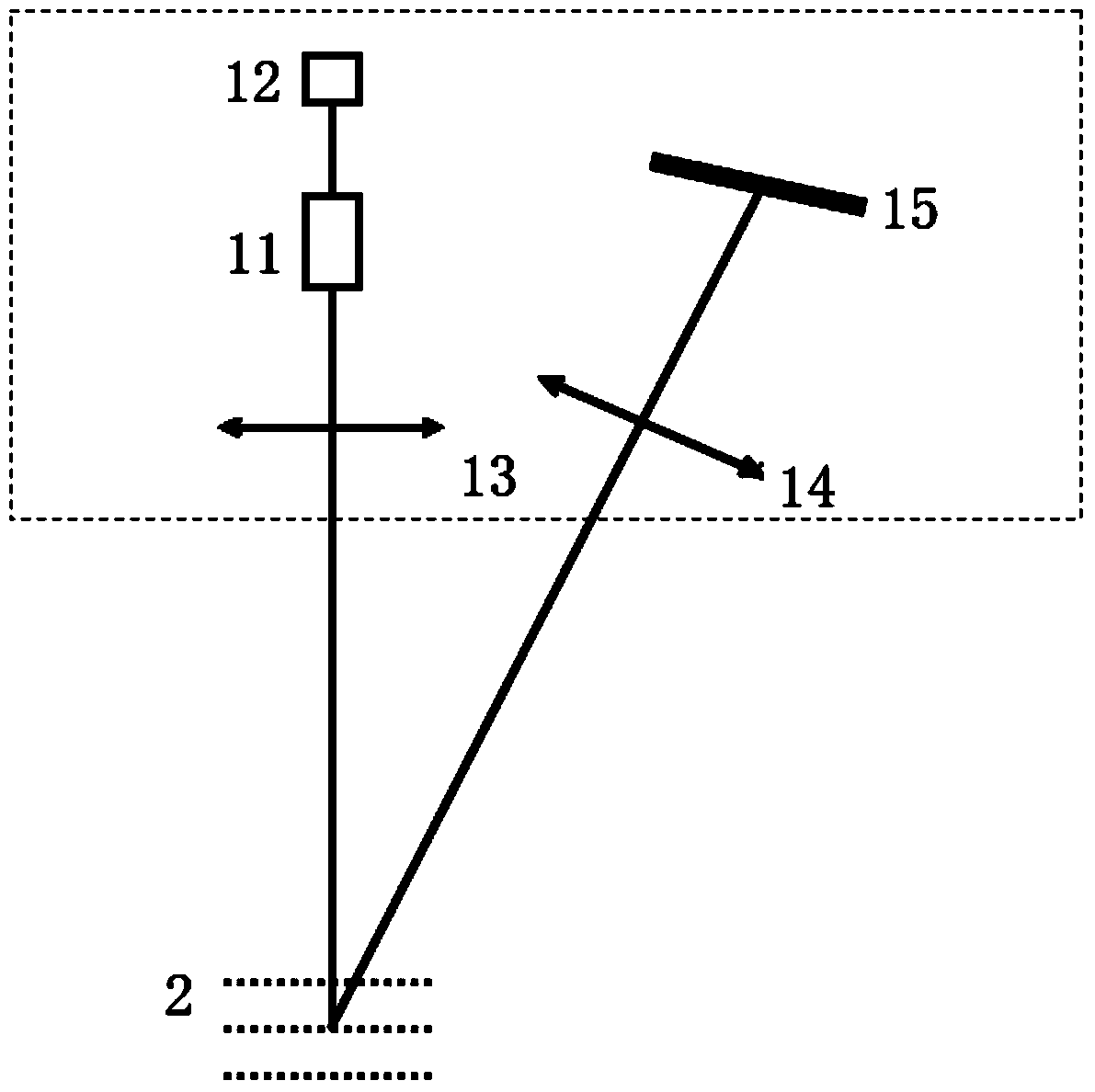

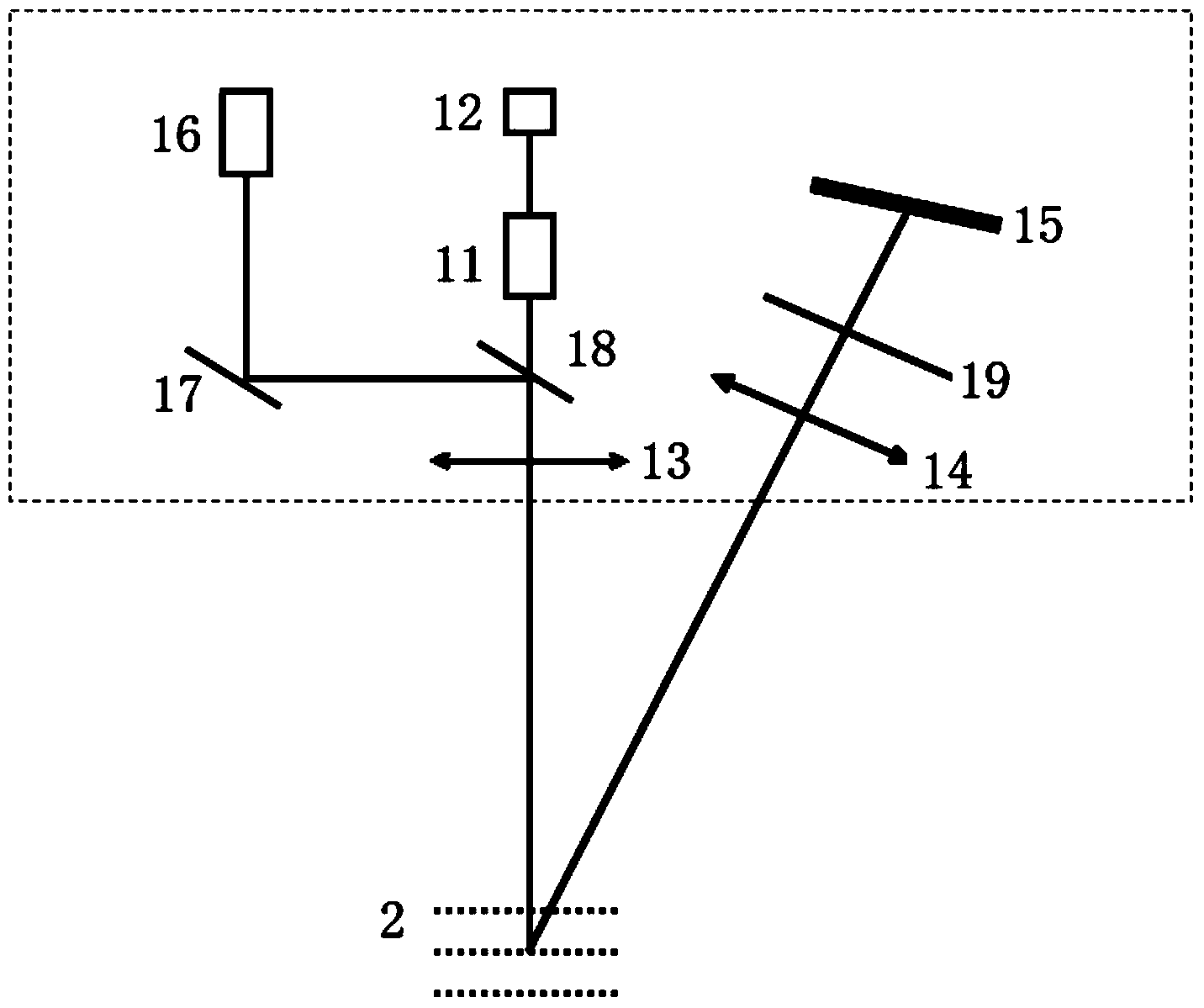

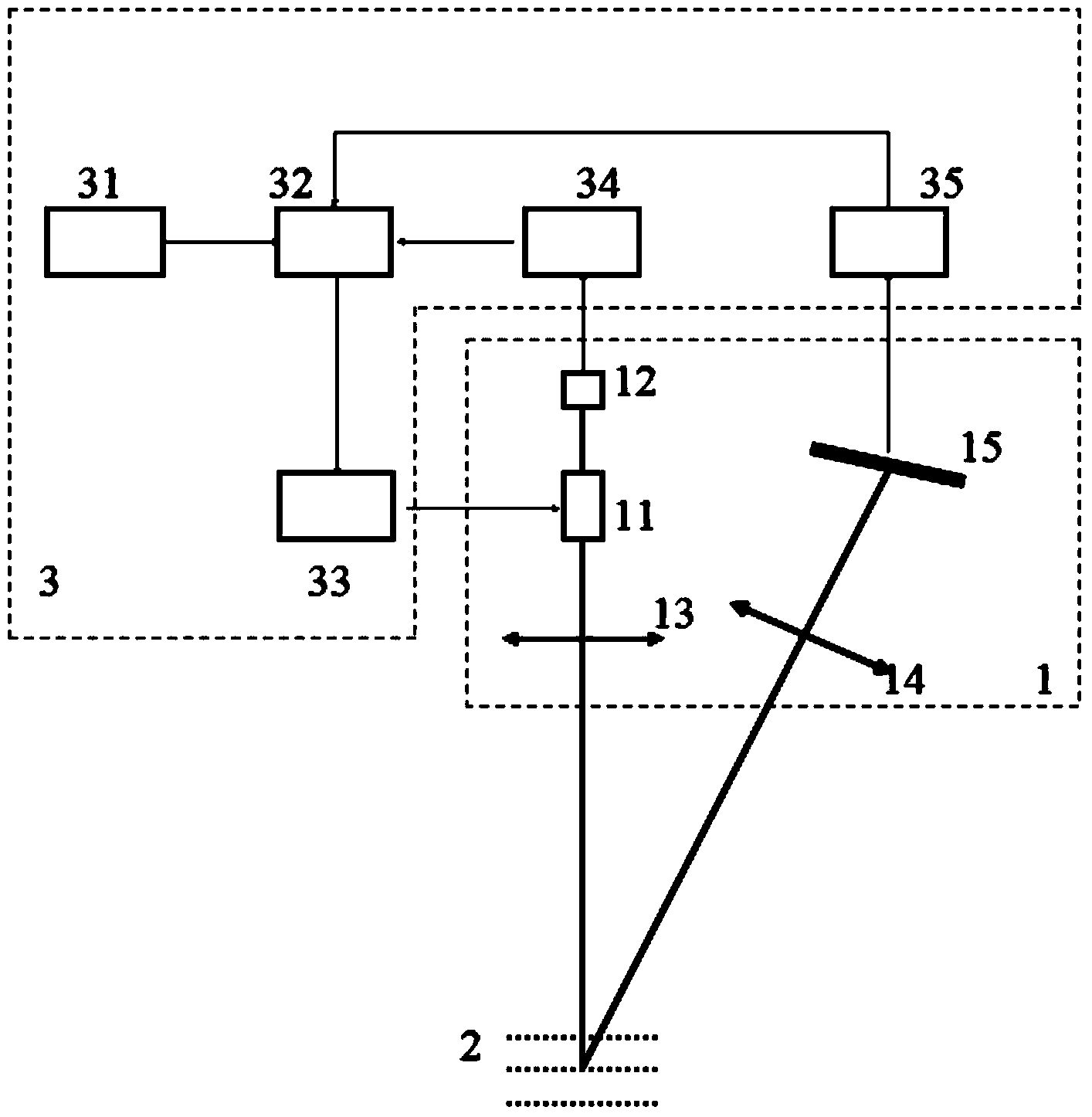

[0022] Such as figure 1 In the shown embodiment 1, the laser vibration and displacement sensor includes a laser 11 , a photodetector 12 , a collimation system 13 , a focusing system 14 and a line array detector 15 .

[0023] The laser 11 emits laser light, which is projected onto the vibrating object 2 through the collimation system 13, and the vertically scattered light returns to the laser 11 through the collimation system 13 to form a self-mixing interference system. The photodetector 12 measures the output power of the laser and demodulates the signal Can realize object 2 high-frequency vibration measurement. The oblique scattering of the object 2 enters the focusing system 14, and the position of the focused spot can be obtained on the line detector 15, forming a laser triangulation structure. The absolute distance of the object can be inverted through the position of the light spot on the detector, and the low-frequency displacement change of the object 2 can be realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com