Y-type double-FBG (fiber Bragg grating) optical fiber vibration sensor for online monitoring hydraulic decoking of coking tower

A vibration sensor and hydraulic decoking technology, applied in the field of sensing, can solve the problem of difficulty in discriminating the thickness of the coke layer, and achieve the effects of convenient accurate propagation, large measurement range and high response frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

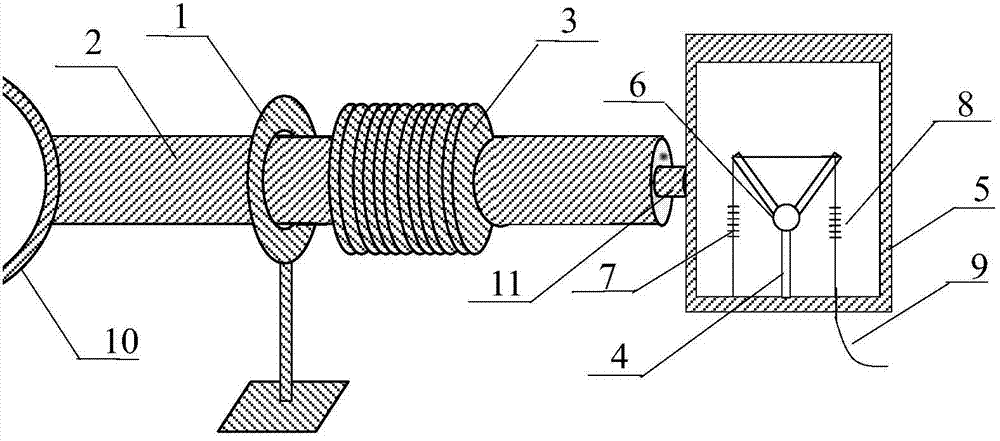

[0024] The structure and realization principle of the sensor of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The Y-type double FBG optical fiber vibration sensor (hereinafter referred to as the sensor) of the coking tower hydraulic decoking on-line monitoring provided by the present invention has a structure such as figure 1 As shown, it includes connection base 1, vibration guide rod 2, heat dissipation structure 3, Y-shaped vibration element 4, sealing shell 5, counterweight body 6, fiber grating 7, fiber grating 8, pigtail 9, contact probe 10, and fixing parts 11, wherein: the connecting base 1 is used for the installation and fixing of the whole sensor, and the connecting base 1 closely contacts the contact probe 10 at the left end of the vibrating guide rod 2 with the wall of the coke tower. The heat dissipation structure 3 is fixed on the vibrating guide rod 2 . The sealing shell 5 is assembled on the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com