Quick Balance Oil Filled Compass

A compass and balance technology, applied in the directions of compass, instrument, surveying and navigation, etc., can solve the problems of low measurement efficiency, low measurement accuracy, and the disk surface cannot quickly restore the balance state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

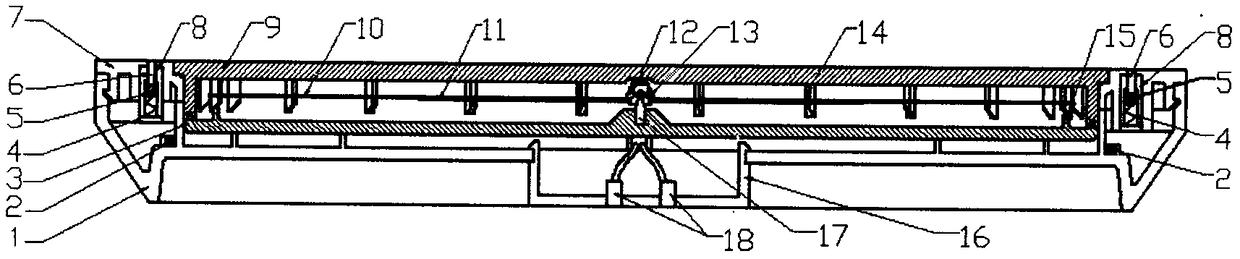

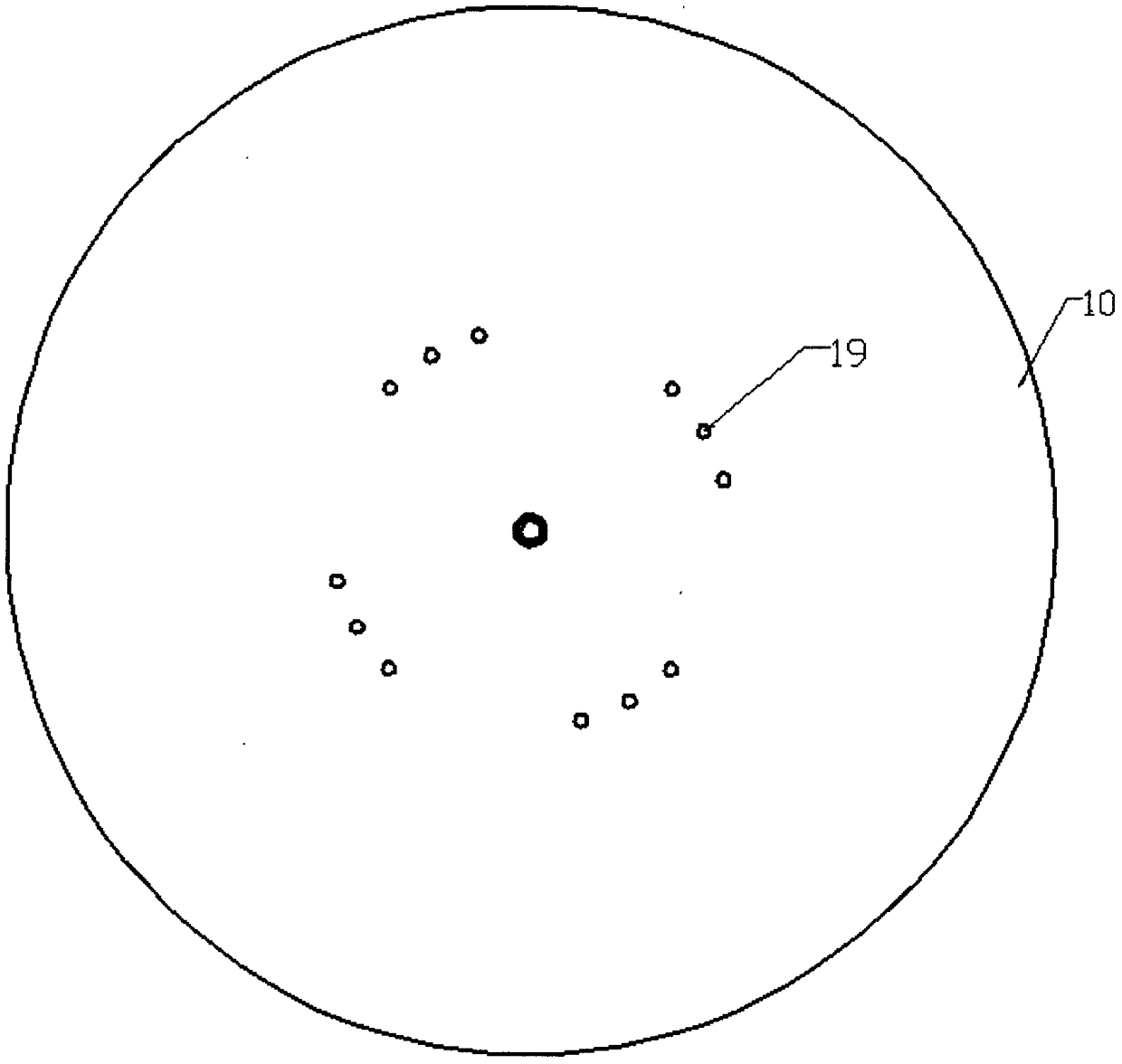

[0024] Refer to the attached drawings, fix the pan / tilt base and the compass protective lower shell 1 and weld the lead wire needed to measure the cursor on the electrode 19 of the pan / tilt base 16, and place the magnetic correction and compensation ring 2 in the magnetic correction and compensation ring groove of the protective lower shell 1. Inside.

[0025] Two in-line laser cursors 20 are installed at the corresponding positions of the laser cursors of the protective lower shell 1.

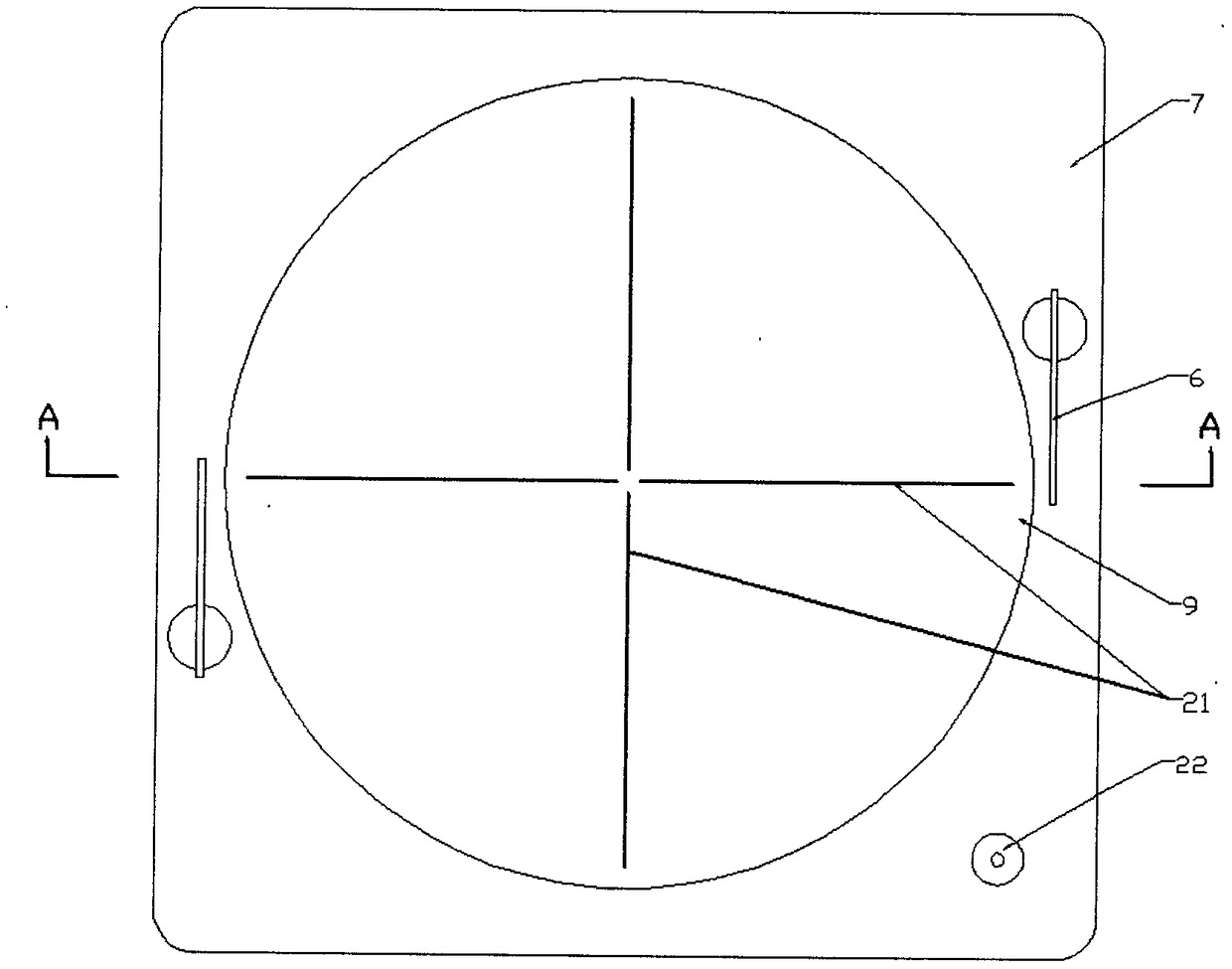

[0026] Assemble the hidden front sight assembly, place it in the corresponding position of the front sight assembly of the protective upper shell 7, and assemble and connect the protective upper shell 7 and the protective lower shell 1 to form a protective shell. An oil-filled sealing bin positioning groove is designed at the center of the opposite side of the protective shell, and a level bubble 22 is designed on the protective upper shell.

[0027] The thimble 17 is fixedly connected to the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com