Testing and calibration method of micromechanical accelerator temperature system

A technology of accelerometer and calibration method, which is applied in the test/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, and measurement devices, etc., which can solve the problems of rising costs, and solve the problem of large temperature influence changes, High fitting accuracy, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Attached below Figure 1-7 Embodiments of the present invention are described.

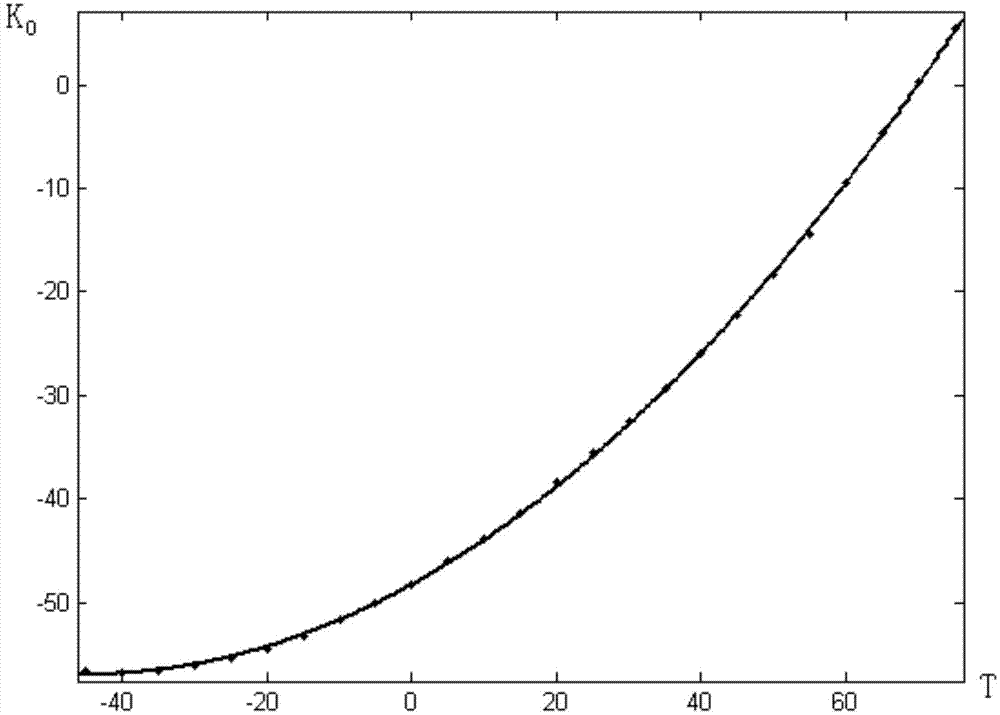

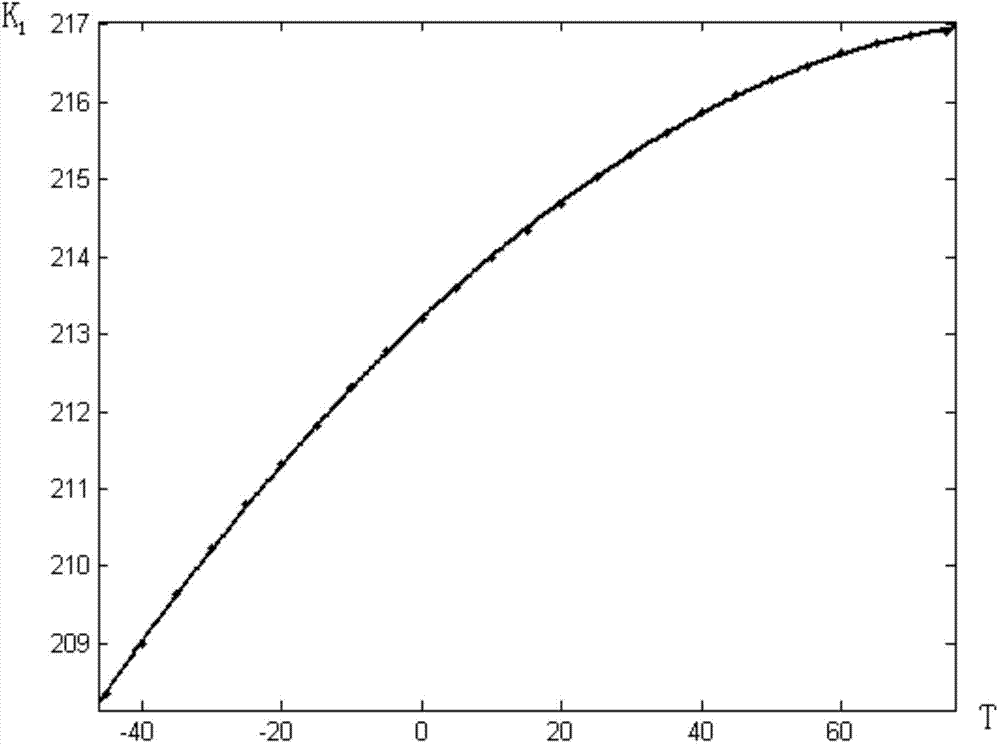

[0021] Taking a certain type of micro-mechanical accelerometer as an example, the specific indicators are as follows: working voltage: 15V±0.15V, DC, bidirectional power supply; working temperature: -45℃~75℃; measuring range: ±15g; bias value K 0 : -2.5×10 -1 g~2.5×10 -1 g; scale factor K 1 : 220mV / g±20mV / g.

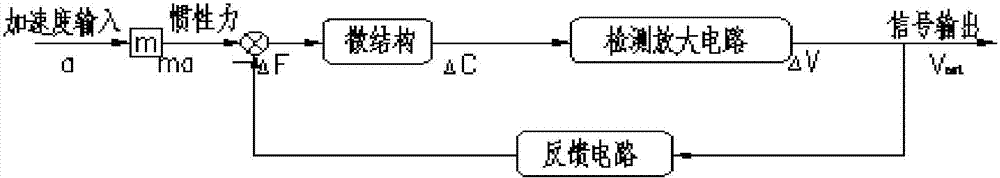

[0022] 1. Working principle: as figure 1 As shown, the micromachined accelerometer closed-loop system is mainly composed of several parts such as the meter head assembly (including the microstructure of the sensitive mass), the detection amplifier circuit and the feedback circuit. When the acceleration input acts on the sensitive mass m to form an inertial force, the capacitor plate on the microstructure is displaced, resulting in a capacitance change ΔC, and the detection amplifier circuit converts the capacitance change ΔC into a voltage change ΔV, and the feedback circuit gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com