Backlight source and assembling method thereof, display panel and display device

A technology for display panels and backlight sources, applied in the directions of light guides, optics, optical components, etc., can solve the problems of reduced light efficiency of backlight sources, cumbersome, and difficult to assemble in place, so as to improve the display effect, improve the backlight effect, and simplify the assembly process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

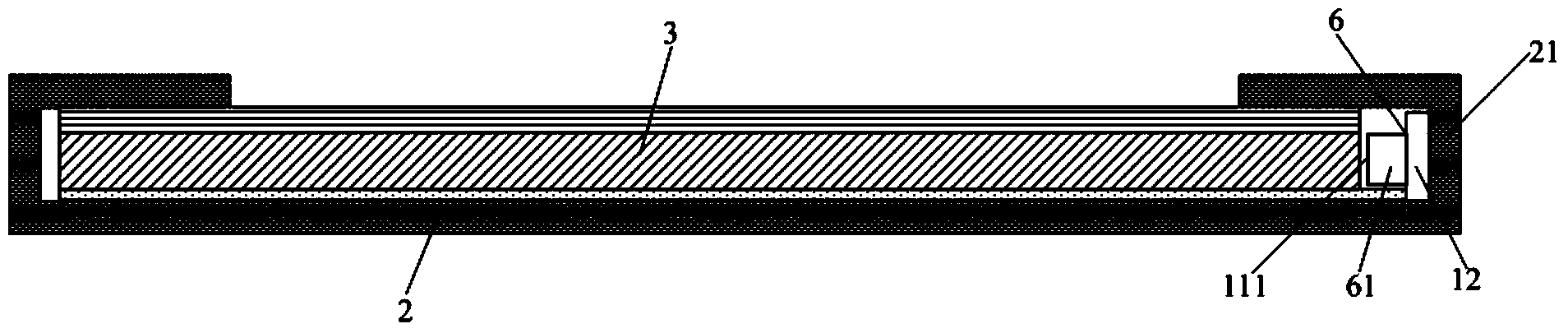

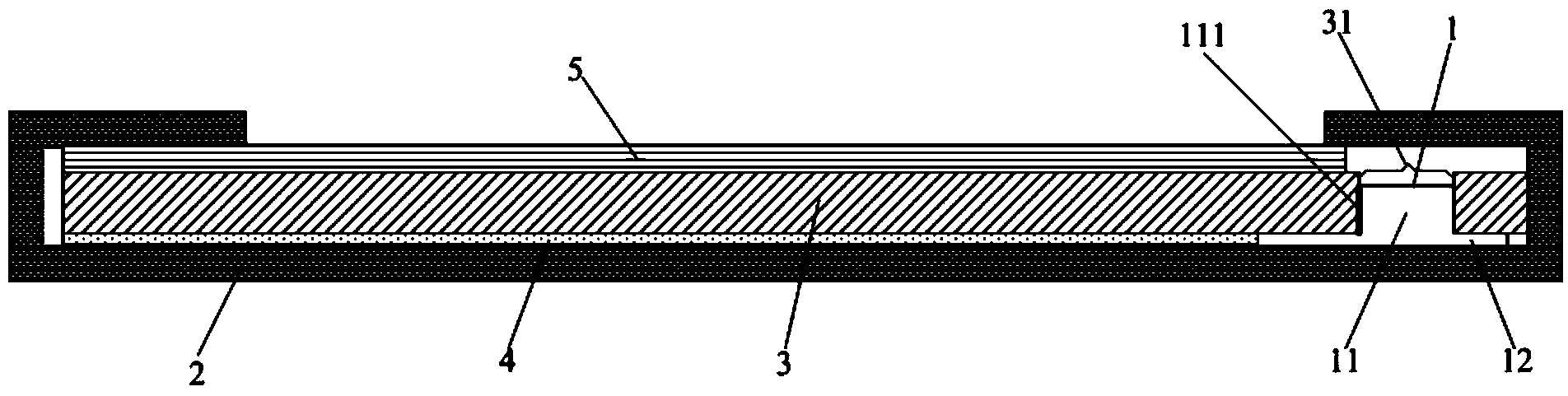

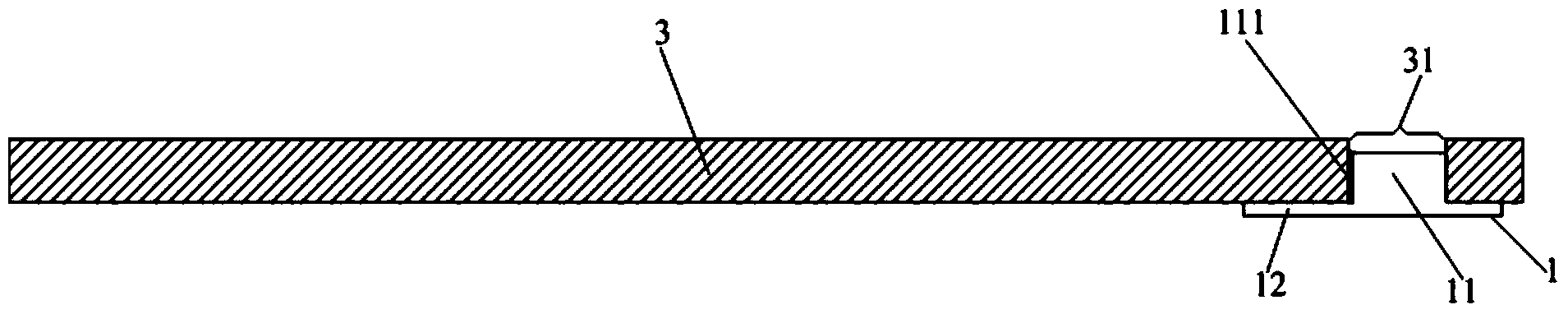

[0030] This embodiment provides a backlight, such as figure 2 and image 3 As shown, it includes a light source 1, a back plate 2, and a light guide plate 3 arranged above the back plate 2. The light source 1 includes a light emitting element 11, and the light guide plate 3 is provided with an accommodation structure 31 at its edge region, and the light emitting element 11 is accommodated in the accommodation Placed in structure 31.

[0031] The light emitting element 11 is accommodated in the accommodating structure 31, so that there is no gap between the light emitting element 11 and the light guide plate 3, so that most of the light emitted by the light emitting element 11 can be incident into the light guide plate 3, Thus, the light utilization rate is improved, and the backlight effect of the backlight source is improved.

[0032] In this embodiment, the light emitting element 11 includes an LED lamp; the accommodating structure 31 is a through hole opened in the light...

Embodiment 2

[0044] This embodiment provides a backlight source. The difference from Embodiment 1 is that Figure 5 As shown, the light-emitting element 11 includes an LED lamp; the accommodating structure 31 is a blind hole opened on the side of the light guide plate 3 facing the backplane 2, and the blind hole is adapted to the size and shape of the LED lamp.

[0045]Correspondingly, the circuit board 12 is pasted on the surface of the light guide plate 3 facing the side of the backplane 2 .

[0046] With such an arrangement, the LED lamp can be just embedded in the blind hole, so that the LED lamp and the blind hole can be fully contacted, and there will be no gap between the two; thus, most of the light emitted by the light-emitting element 11 can be Incident into the light guide plate 3, thereby improving the utilization rate of light, and also improving the backlight effect of the backlight source.

[0047] It should be noted that the accommodating structure 31 can also be a blind h...

Embodiment 3

[0051] This embodiment provides a display panel, including the backlight source in any one of Embodiments 1-2.

[0052] The display effect of the display panel is improved by using the backlight source in any one of Embodiments 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com