Positive sequence and negative sequence combination-based three-dimensional process model generation method

A process model and model technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of many manual interactions, no support for collaborative and synchronous work, and low efficiency of 3D process model generation, so as to achieve standardized management, Ensure reasonable acquisition and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

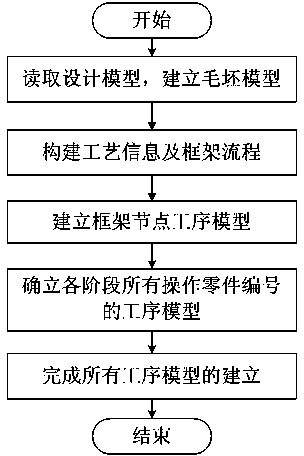

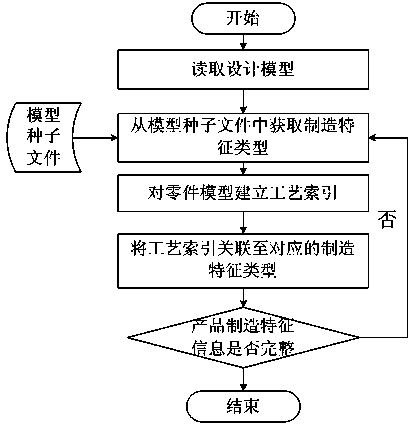

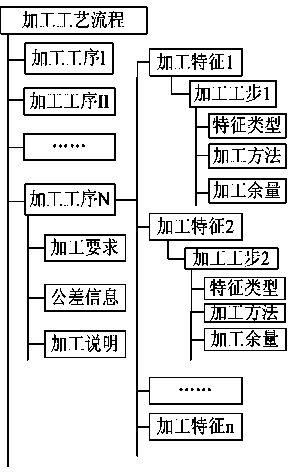

[0017] A three-dimensional process model generation method based on the combination of forward and reverse sequences proposed by the present invention adopts the combination of forward and reverse sequences of the three-dimensional process model, divides the process into frame node processes and sub-processes, and divides the process model into frame node process models And the sub-process model, constructing a structured process by reading the prior process knowledge and decision results in the model seed file to realize the association between manufacturing features, processes and modeling operations. The frame node process model is created by the forward sequence method, and the generation efficiency is high; on the basis of the frame node process model, the sub-process model is constructed by the reverse sequence method. In the process of sub-process model generation, based on the association and correspondence between manufacturing features, processes and modeling operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com