Efficient cadmium telluride nanocrystalline Schottky junction solar cell with modified anode interface and preparing method thereof

An anode interface, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable carrier separation and extraction, affecting hole transport, etc., to improve the solar open circuit voltage and fill factor, achieve ohmic Contact, the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2. Preparation of anode interface layer material:

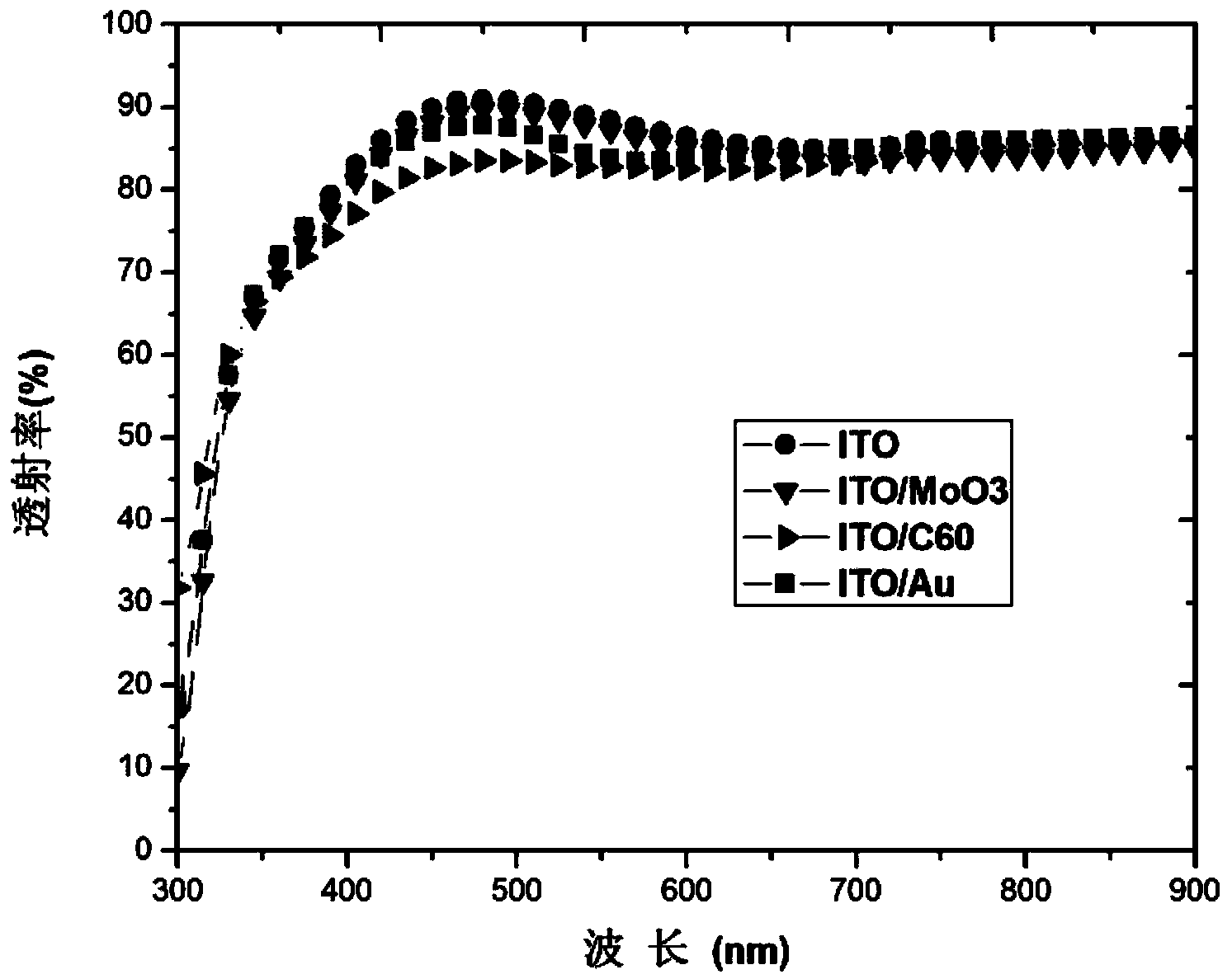

[0036] When choosing Au or MoO X (x value is 2~3) When it is used as the anode interface layer material, put the cleaned and dried ITO substrate into the DM-300B vacuum coating chamber for plating, turn on the mechanical pump and molecular pump, and when the coating chamber reaches 3 ×10 -4 Start to evaporate Au or MoO after the high vacuum of Pa X , the evaporation rate and thickness are monitored in real time by a quartz vibrator film thickness monitor, and the evaporation rate is When choosing C 60 When used as an anode interface layer material, C 60 The anode interface layer was prepared by solution processing, and the C 60 Dissolved in p-xylene to obtain a purple solution with a concentration of 5mg / ml, the solution was spin-coated on the ITO substrate at different speeds to obtain different thicknesses of C 60 The film was heated at 200°C for 20 minutes, and finally a uniform and light-transmitting C 60 f...

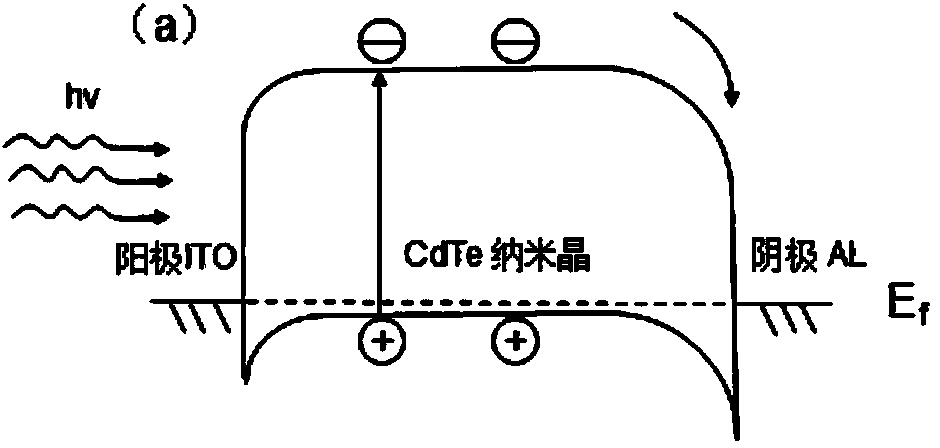

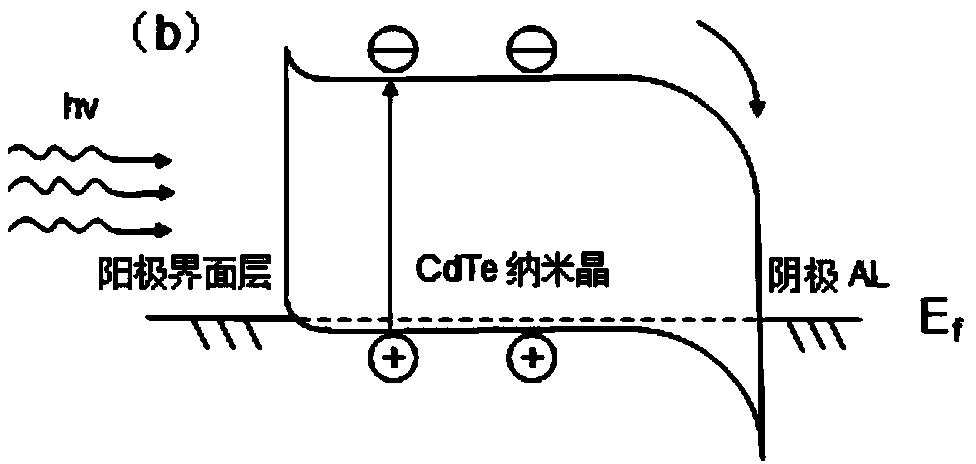

Embodiment 1

[0044] Embodiment 1 Different thickness MoO X Effect on Device Performance

[0045] According to the Schottky theory, to make the P-type cadmium telluride form a stable ohmic contact with the anode, the work function of the anode must be higher than that of the active layer cadmium telluride. Then the work function of the anode ITO is only 4.7, while the work function of the active layer CdTe is about 5.1 to 5.3. When the two materials are in contact, electrons will flow from one side of the low work function (ITO) to the other side (CdTe) until Fermi The energy level is equal. Thus, the anode ITO will be slightly positively charged while the high work function material CdTe will become slightly electronegative. Finally, a built-in electric field is formed at the interface, causing the energy band at the semiconductor interface to bend downward, which affects the extraction and collection of holes, such as Figure 1a shown. On the contrary, adding a layer of high work funct...

Embodiment 2

[0050] Embodiment 2 Effect of different thicknesses of Au on device performance

[0051] Repeat Example 1, select high work function metal Au (work function is 5.1eV) as the anode interface layer, the thickness is respectively 0.5nm, 1nm, 2nm, other conditions remain unchanged. The experimental results are summarized in Table 3.

[0052]It can be seen from Table 3 that the addition of Au significantly improves the open circuit voltage and fill factor, especially the device optimization effect of 1nm Au is the best, the open circuit voltage and fill factor are increased by 22% and 39% respectively, and the overall efficiency is increased from 4.3% to 5.3%. Since Au has a large absorption in the visible light range, as the thickness of Au increases, the light absorption of the active layer will decrease, and the current will continue to decrease. Compared with 0.5nm Au, the addition of 1nm Au can form a more uniform and dense island-like Au, fully realize the ohmic matching be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap