Bus-bar clamp

A technology of busbar clamps and insulating bases, applied in the field of busbar clamps, can solve problems such as limited product body bearing strength, electrical hidden dangers of power distribution products, and influence on electrical performance, and achieve various installation and fixing methods, solve eddy current loss, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

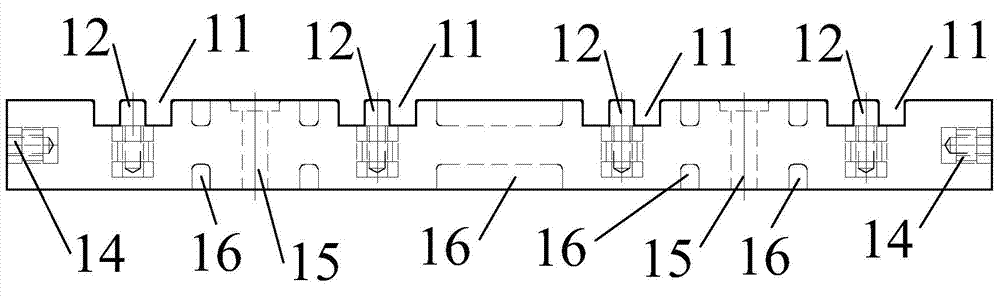

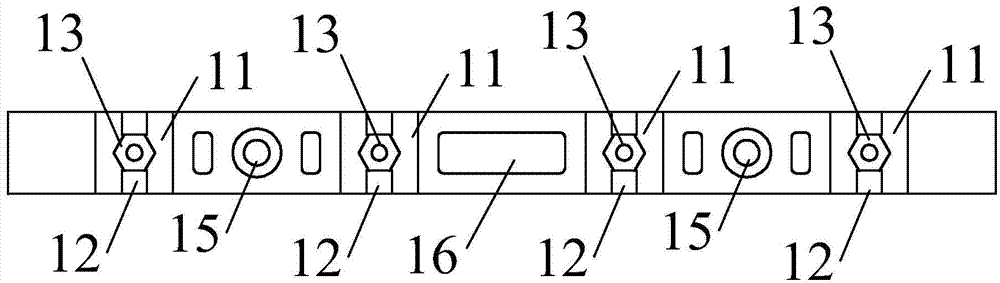

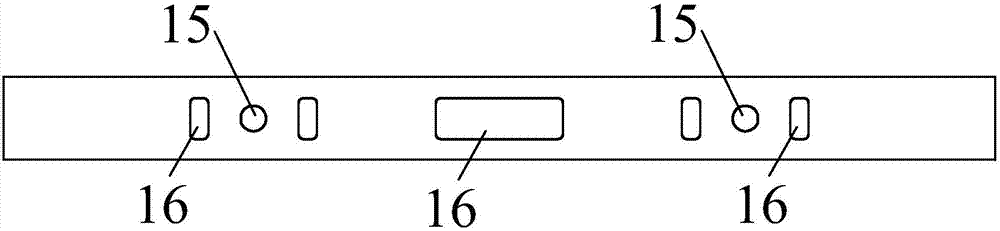

[0020] For the convenience of description, in this embodiment, the bus clamp is figure 1 When placing as shown, define the direction with the longest side length of the bus clamp as "length direction", and define the direction with the other side as "height direction", such as figure 2 The direction of the shortest side length shown in the top view is defined as the "width direction", the side where the copper bar installation groove 11 is located is defined as the "top surface", and the corresponding other side is defined as the "bottom surface", but it is not limited to this in practical applications .

[0021] refer to Figure 1 to Figure 4 , The busbar clamp of the present invention includes an insulating base of an integral structure, which is an integrally formed base added with SMC composite material, which increases toughness and can withstand an instantaneous short-circuit current of 80KA / s.

[0022] On the top surface of the insulating base, several groups of copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com