Cladding material for stainless-steel-clad steel plate and stainless-steel-clad steel plate obtained using same, and process for producing same

A technology of composite materials and composite steel plates, applied in chemical instruments and methods, manufacturing tools, welding/cutting media/materials, etc., can solve the problem of improving the reliability of the joint interface between base metal and composite materials, difficult to deal with high-grade steel and multiple species and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

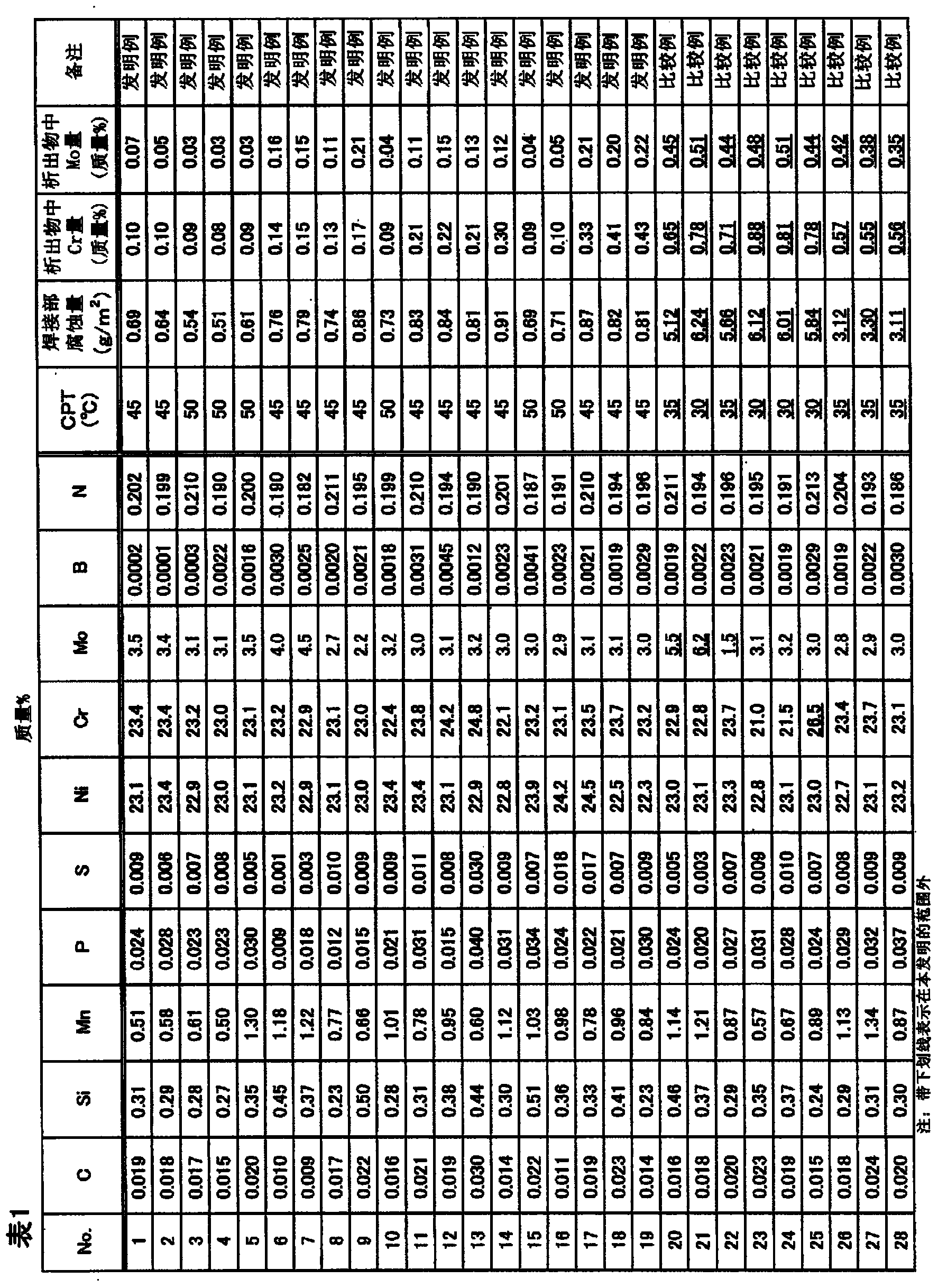

[0074] Examples of the present invention will be described below.

[0075] Austenitic stainless steel having the composition shown in Table 1 and a steel material of the SS400 composition system (hereinafter, sometimes simply referred to as "ordinary steel") were used. Combining SS400 series steel with a plate thickness of 150 mm as the base material, austenitic stainless steel with a plate thickness of 13 mm as the composite material, and ordinary steel with a thickness of 26 mm on the surface of the composite material as a sacrificial material, and assembled into a thickness of ( 150+13+26)mm billet.

[0076] Next, heating at 1230° C., hot finish rolling at 970° C., holding at 910° C. for 10 minutes, and air cooling were performed to manufacture a composite steel having a thickness of (29.5+2.5) mm.

[0077] For the stainless clad steel obtained by the above method, the pitting corrosion resistance of the composite material was evaluated by ASTM G48-03 method E shown below....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com