Camshaft unit

A technology of camshafts and camshaft adjusters, which is applied to engine components, machines/engines, mechanical equipment, etc., and can solve problems such as manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

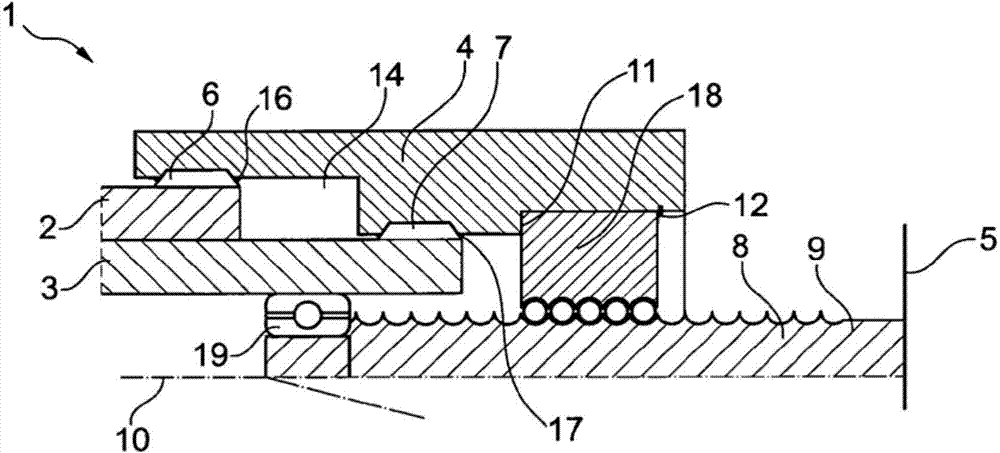

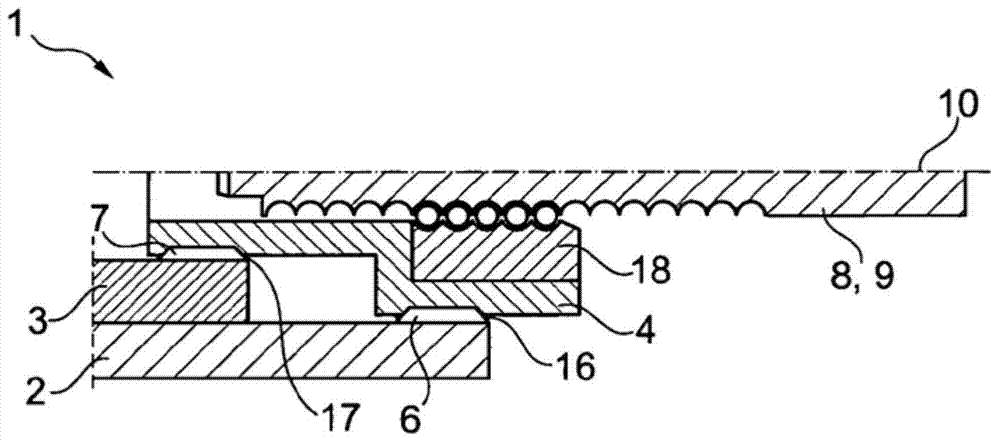

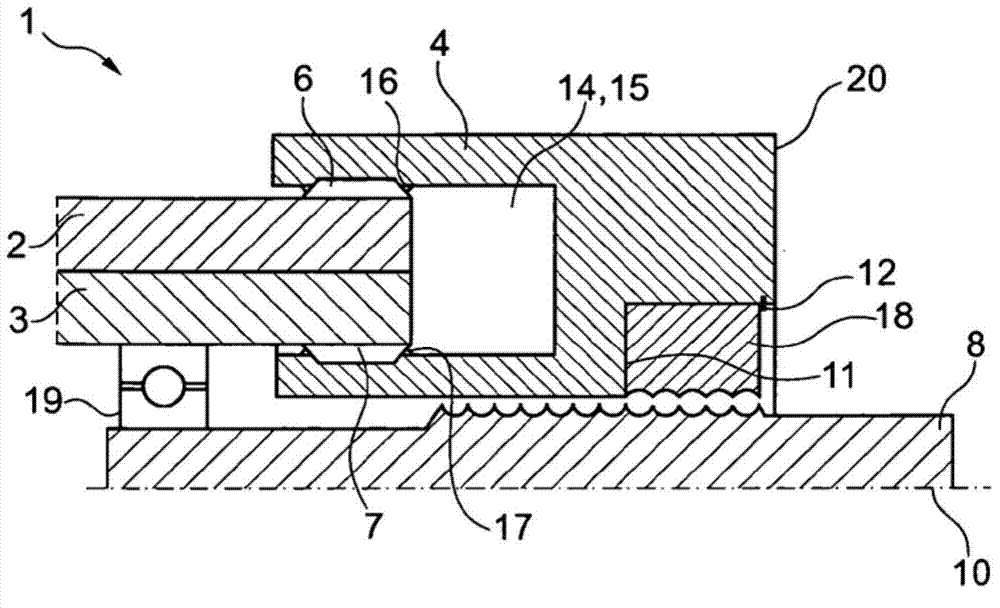

[0026] figure 1 A first camshaft unit 1 is shown, which has a first camshaft 2 , a second camshaft 3 arranged concentrically to the first camshaft 2 , and a connecting element 4 . The connecting element 4 is connected to the first camshaft 2 via a first toothing 16 and to the second camshaft via a second toothing 17 . One of the toothing pairs 6 , 16 and 7 , 17 is designed as a helical toothing and the other pair is designed as a straight toothing.

[0027] The connecting element 4 is designed as a stepped sleeve which has two different inner radii and surrounds the two camshafts 2 , 3 radially on the outside. The inner radius difference corresponds to the ring diameter of the outer camshaft which is now formed by the first camshaft 2 . The two camshafts 2 , 3 extend axially to different extents into the inner cavity 14 of the connecting element 4 . The toothing 16 , 17 of the connecting element 4 meshes with the mating toothing 6 , 7 of the camshaft 2 , 3 . All three comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com