Scanning signal line drive circuit and display device provided with same

A technology for scanning signal lines and driving circuits, which is applied in the field of active matrix display devices, can solve problems such as increased load and increased power consumption, and achieve the effects of reducing power consumption and suppressing electromagnetic interference (EMI)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

[0062]

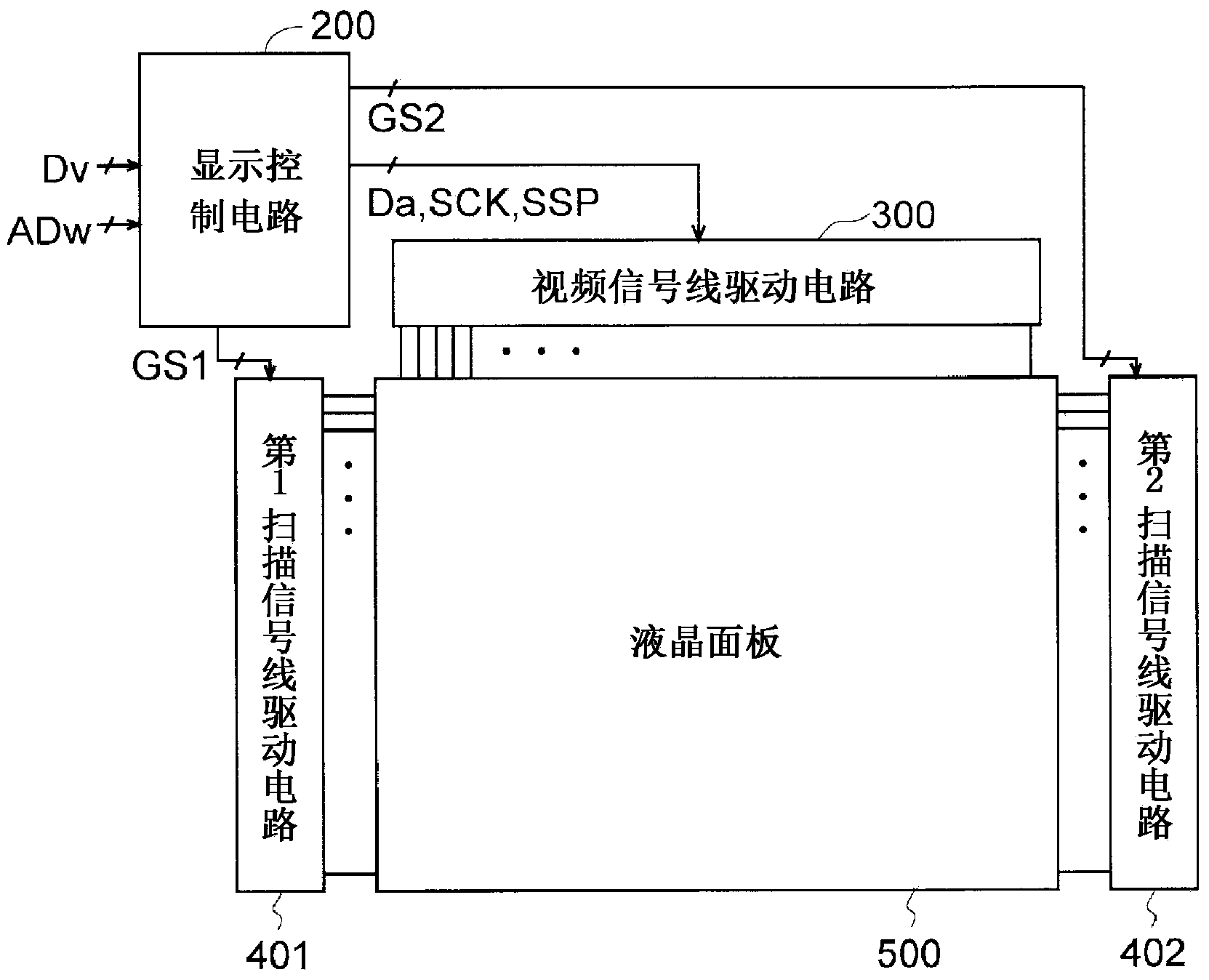

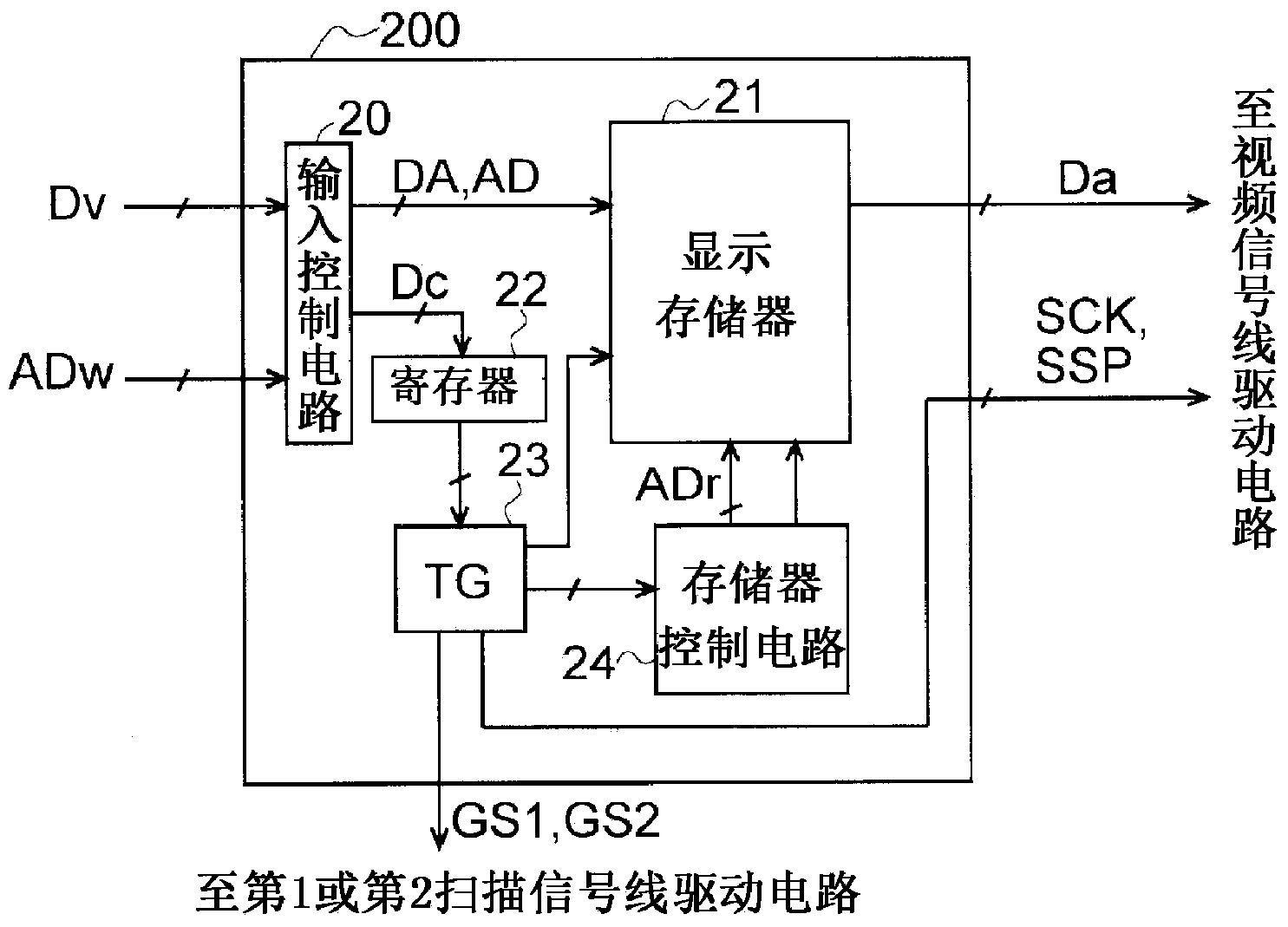

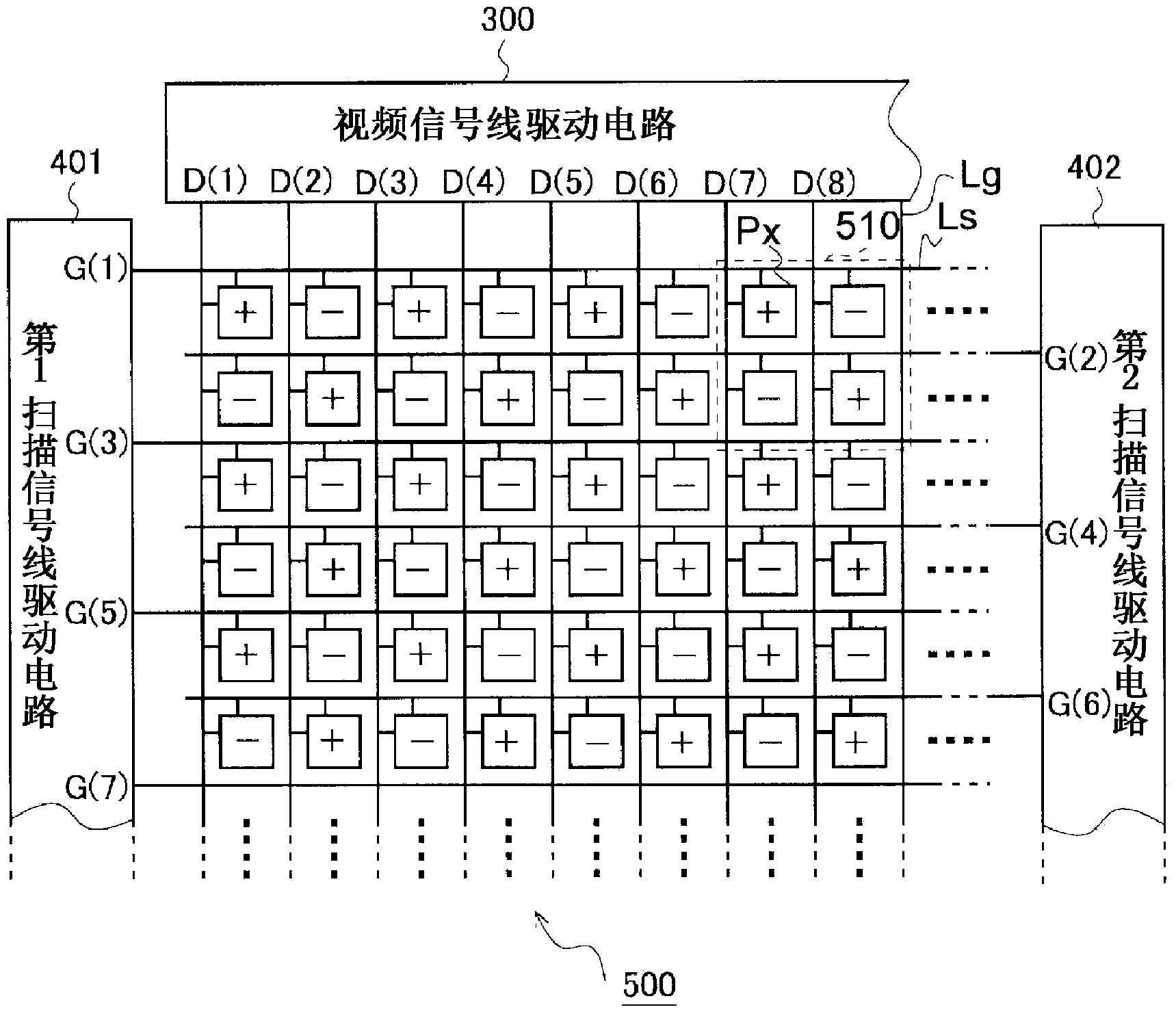

[0063] figure 1 It is a block diagram showing the configuration of a liquid crystal display device according to an embodiment of the present invention. The liquid crystal display device comprises: a display control circuit 200; a video signal line drive circuit (also referred to as a "source drive circuit" or a "column electrode drive circuit") 300; a first and a second scanning signal line drive circuit (the circuit Also referred to as “gate drive circuit”, “row electrode drive circuit”) 401 , 402 ; and active matrix type liquid crystal panel 500 .

[0064] Among these circuits, the above-mentioned first and second scanning signal line driver circuits 401 and 402 are integrally formed (so-called monolithic) on an element substrate which is a glass substrate together with a pixel circuit described later, and the display control circuit 200 and the video signal The line driver circuit 300 is formed in an IC chip and mounted on an element substrate. A liquid crysta...

no. 2 Embodiment approach >

[0108]

[0109] The configuration and the figure 1 The configuration shown is the same, and the configuration of the liquid crystal panel 500 is also the same as image 3 etc. are the same, and therefore, the same reference numerals are attached to the same constituent elements, and detailed descriptions are omitted. In addition, the configurations of the shift register circuits included in the first and second scanning signal line driving circuits 401 and 402 are also the same, but their operations are slightly different. In addition, related to this, the scanning signal lines connected to the first and second scanning signal line drive circuits 401 and 402 are different from those of the first embodiment. Below, refer to Figure 9 Explain in detail.

[0110] Figure 9 It is a diagram for explaining the selection and connection relationship of scanning signal lines and the relationship between each signal. with the above Figure 7 The composition shown is different, ...

no. 3 Embodiment approach >

[0119]

[0120] The configuration and the figure 1 The configuration shown is the same, and the configuration of the liquid crystal panel 500 is also the same as image 3 etc. are the same, and therefore the same components are given the same reference numerals and detailed descriptions are omitted. In addition, the configuration of the scanning signal line driver circuit is also the same as that of the first or second embodiment, and thus description thereof will be omitted.

[0121] In this embodiment, different from the first and second embodiments, the so-called time-division driving method is adopted, and the video signal lines Ls of the liquid crystal panel are divided into a plurality of video signal line groups in groups of three. The line group (three video signal lines Ls in the same group) is connected to one output terminal of the video signal line drive circuit 300 via the three analog switches in the same group. In this way, the output terminals of the video...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com