Drilling fixture for two vertical holes on fabric-feeding presser foot of sewing machine

A technology of mutually perpendicular, drilling fixtures, applied in the field of tooling fixtures, to achieve the effect of simple and compact structure, ensuring processing quality, and simple and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

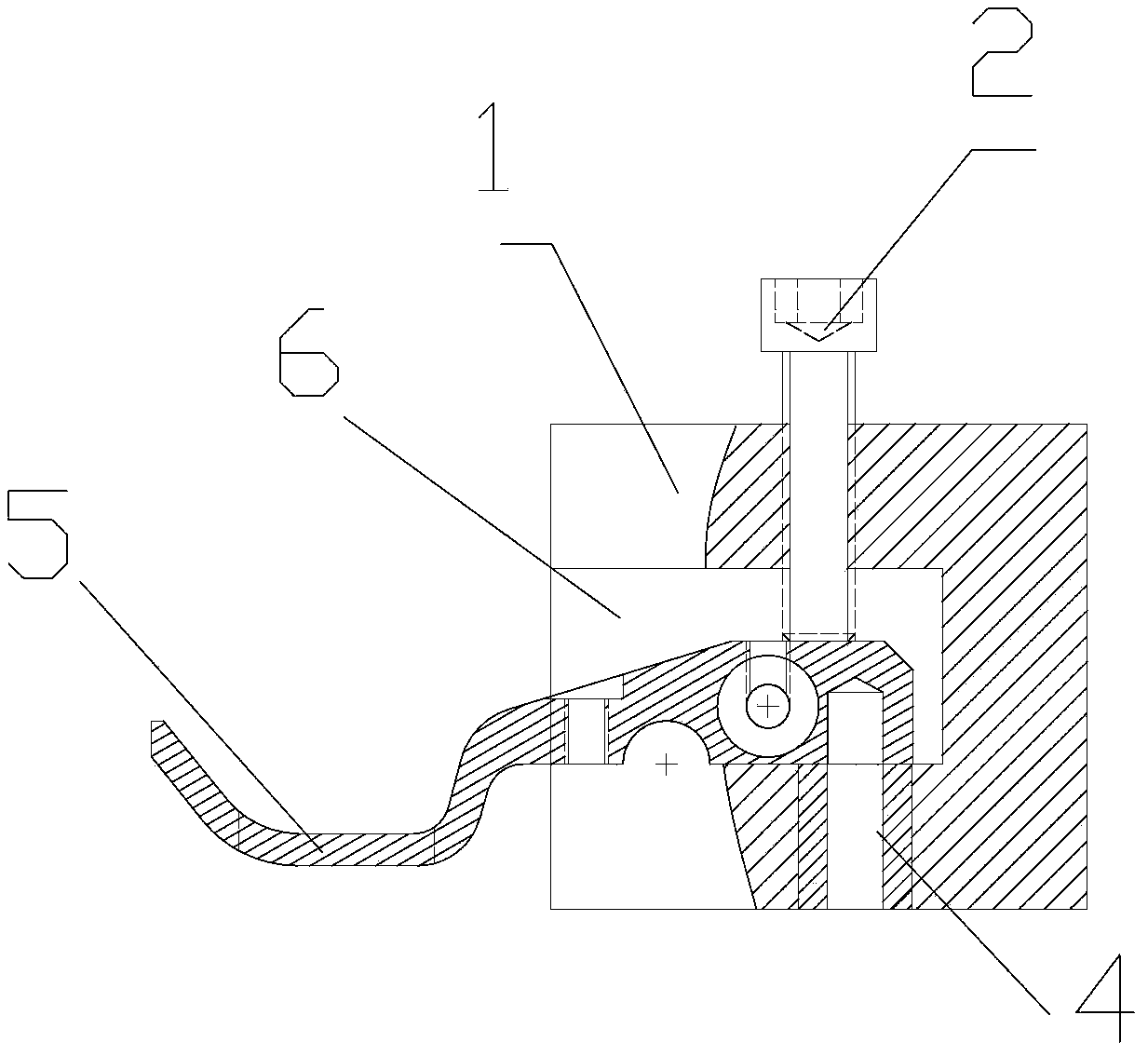

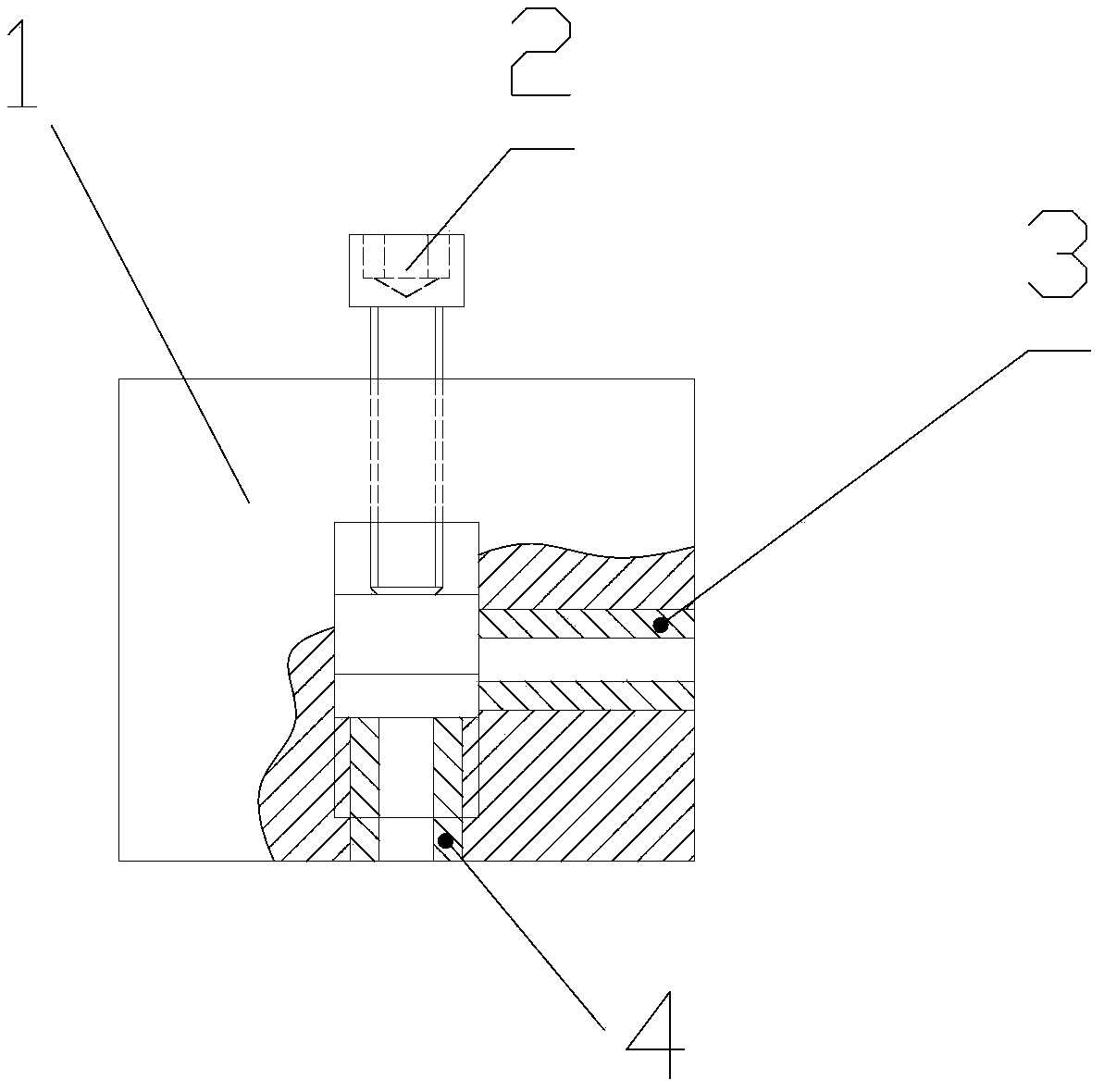

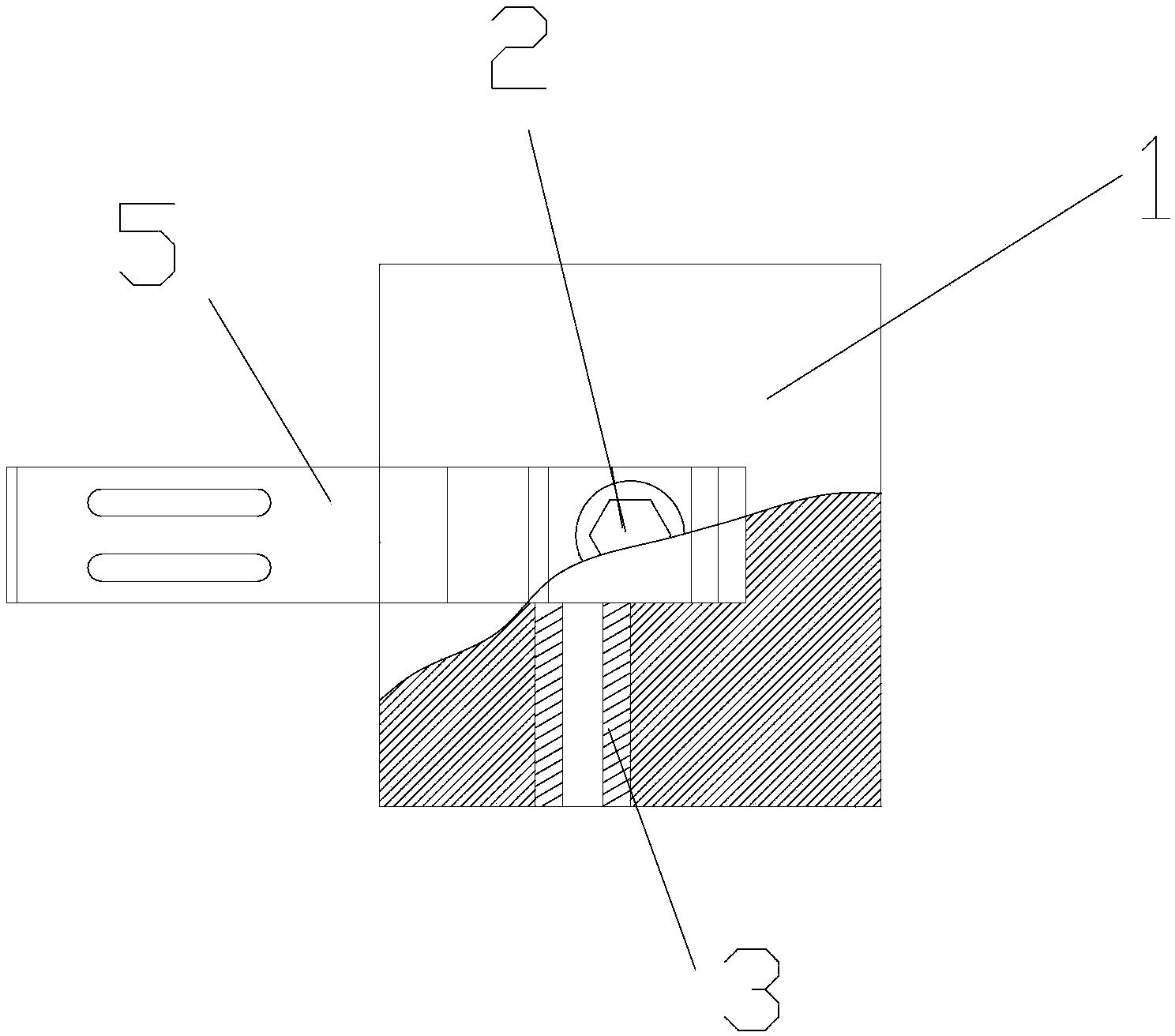

[0021] see attached Figure 1-3 , the present invention provides a sewing machine cloth feeding presser foot drilling fixture with two holes perpendicular to each other, including a fixture body 1, the shape of the fixture body is a cube, and a rectangular opening groove 6 is horizontally provided on one side of the fixture body. The rectangular opening groove is connected with the pressing mechanism, and the jig body is provided with a drilling mold. The bottom edge of the rectangular opening groove is parallel to the side of the fixture body, constituting the positioning base surface of the fixture. The width and depth of the rectangular opening groove match the width and thickness of the workpiece. Two drilling molds of φ3.8 and φ3 are set on the fixture body corresponding to the designed holes of the workpiece, and the drilling molds are arranged at right angles to each other to complete the processing of two holes at right angles to each other. Drilling jigs (3) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com