Hot-press

A technology of heat press and rack, applied in heat press. It can solve the problems of workbench safety hazards, long process interval, low work efficiency, etc., and achieve the effect of high working efficiency, less space occupation and rapid cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

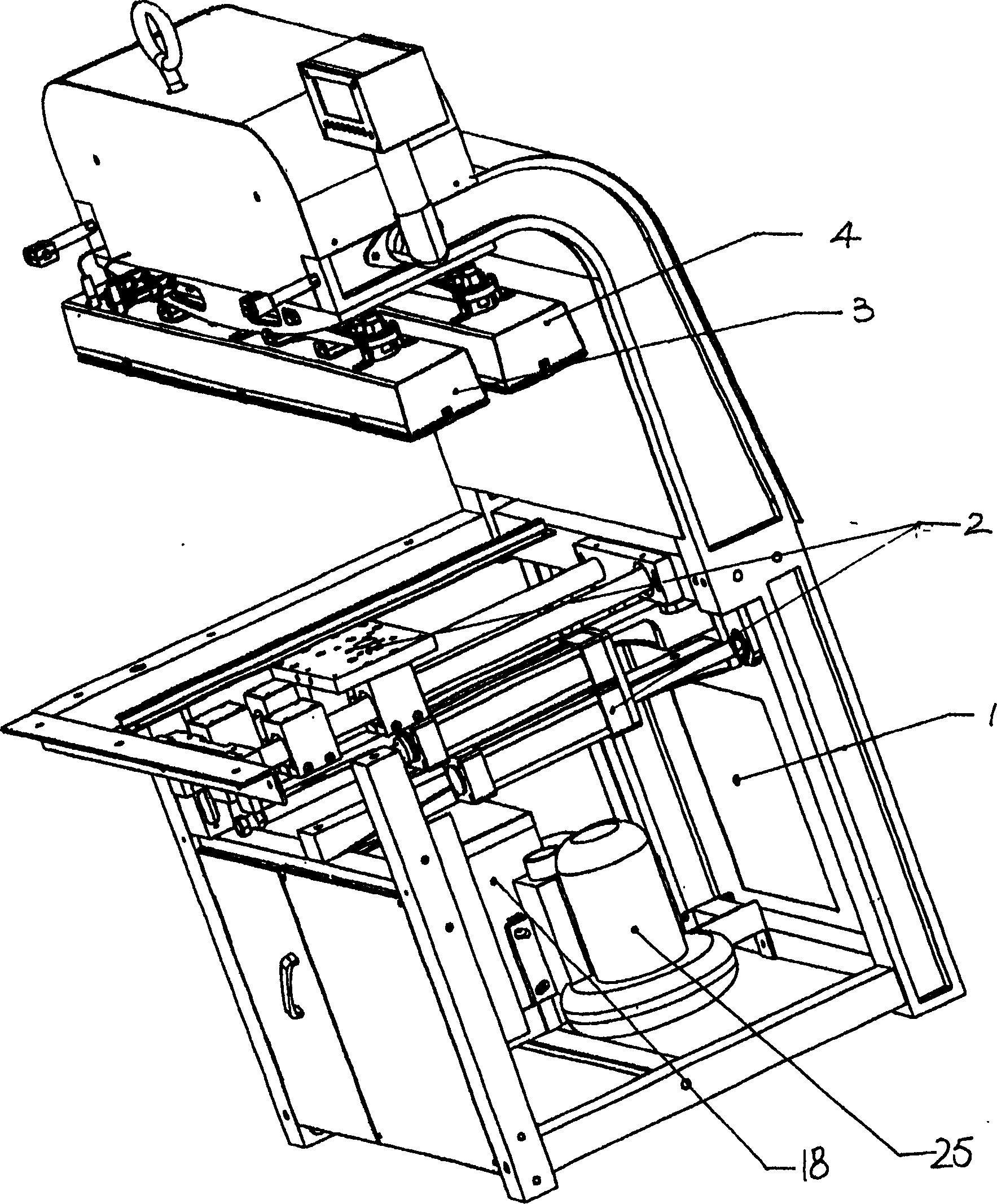

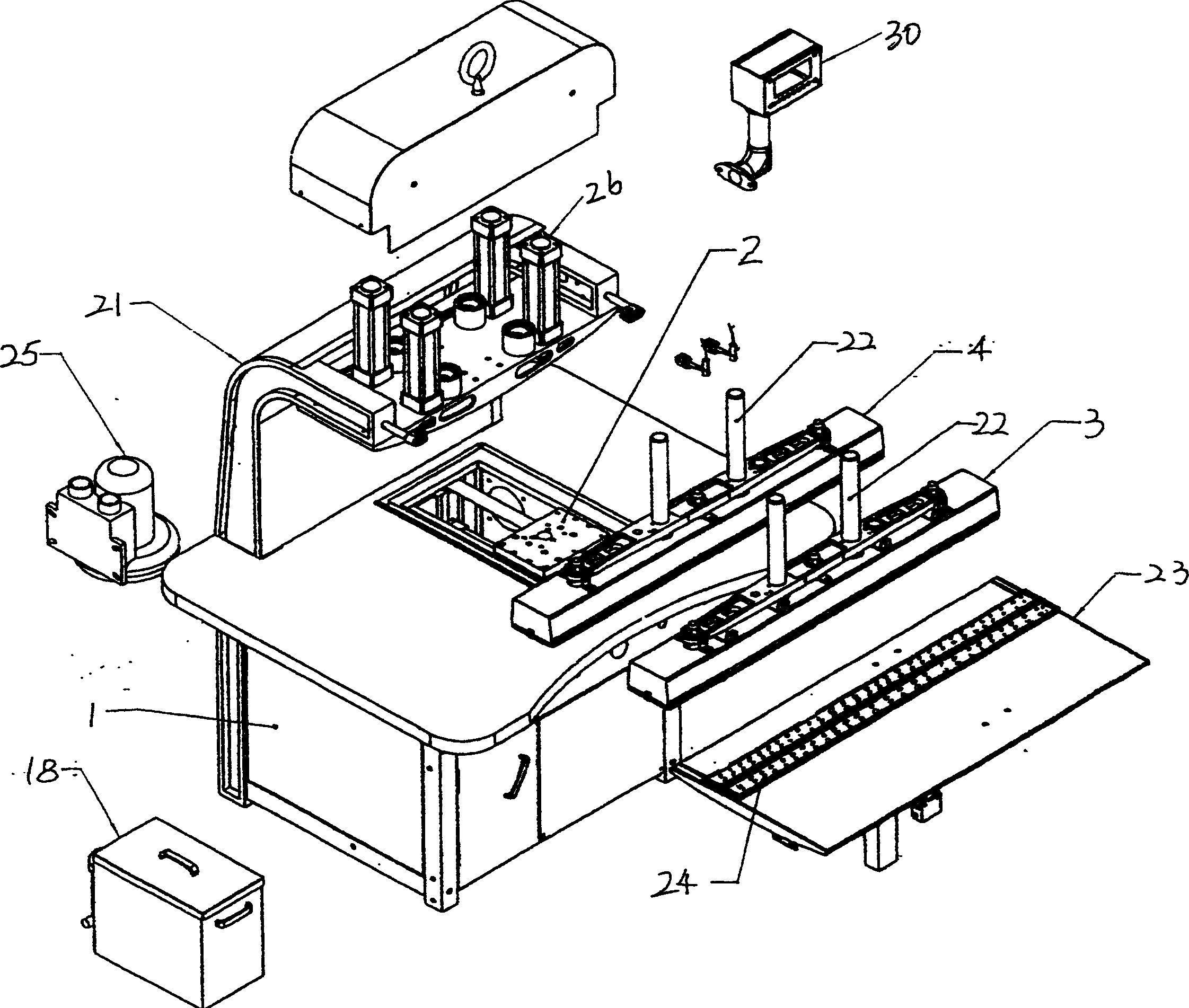

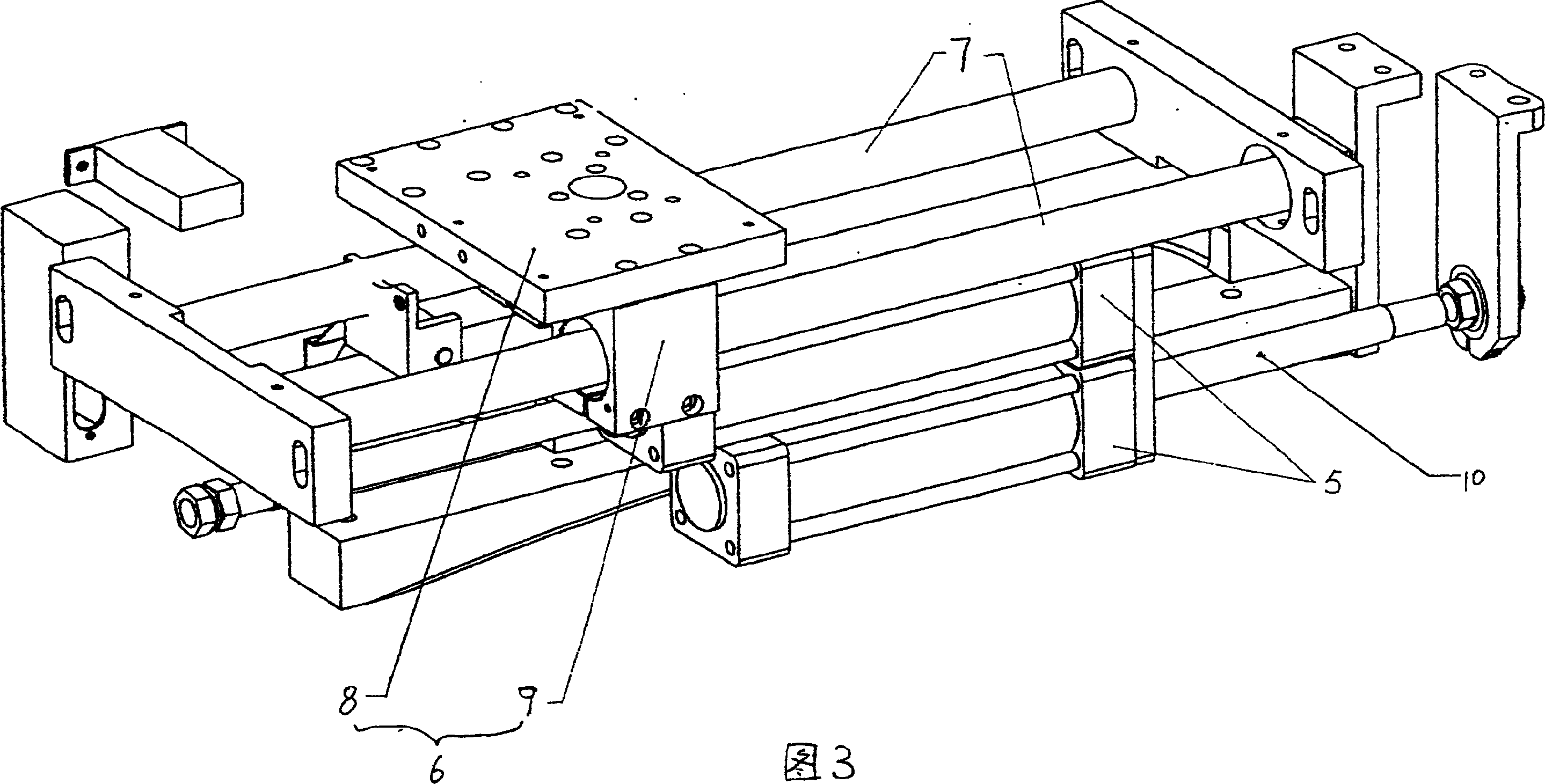

[0019] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 , 2 Among them, the novel hot press machine of the present invention includes a frame 21, a cold-press setting device 4 connected to the frame 21 through a guide column 22, a hot-press bonding device 3, and a workbench 23 that can move relative to the frame 21. The pressure setting device 4 is arranged in parallel with the thermocompression bonding device 3 , corresponding to the positions of the working table 23 at different stations. They are respectively driven by the lift cylinder 26 installed on the frame 21 upper end to move them up and down, and the cabinet 1 below the frame 21 is provided with a driving mechanism 2 that drives the workbench 23 to reciprocate. When starting up, the workbench driving device 2 drives the workbench 23 to move forward, the thermocompression bonding device 3 descends and presses the workbench 23, then the thermocompression bondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com