An automatic drilling machine with double turntables and double drill stands

A double turntable and drilling machine technology, which is applied in boring/drilling, drilling/drilling equipment, driving devices, etc., can solve problems such as difficulty in guaranteeing processing quality, poor consistency of finished workpieces, and low processing efficiency. The effect of good consistency, low manufacturing cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

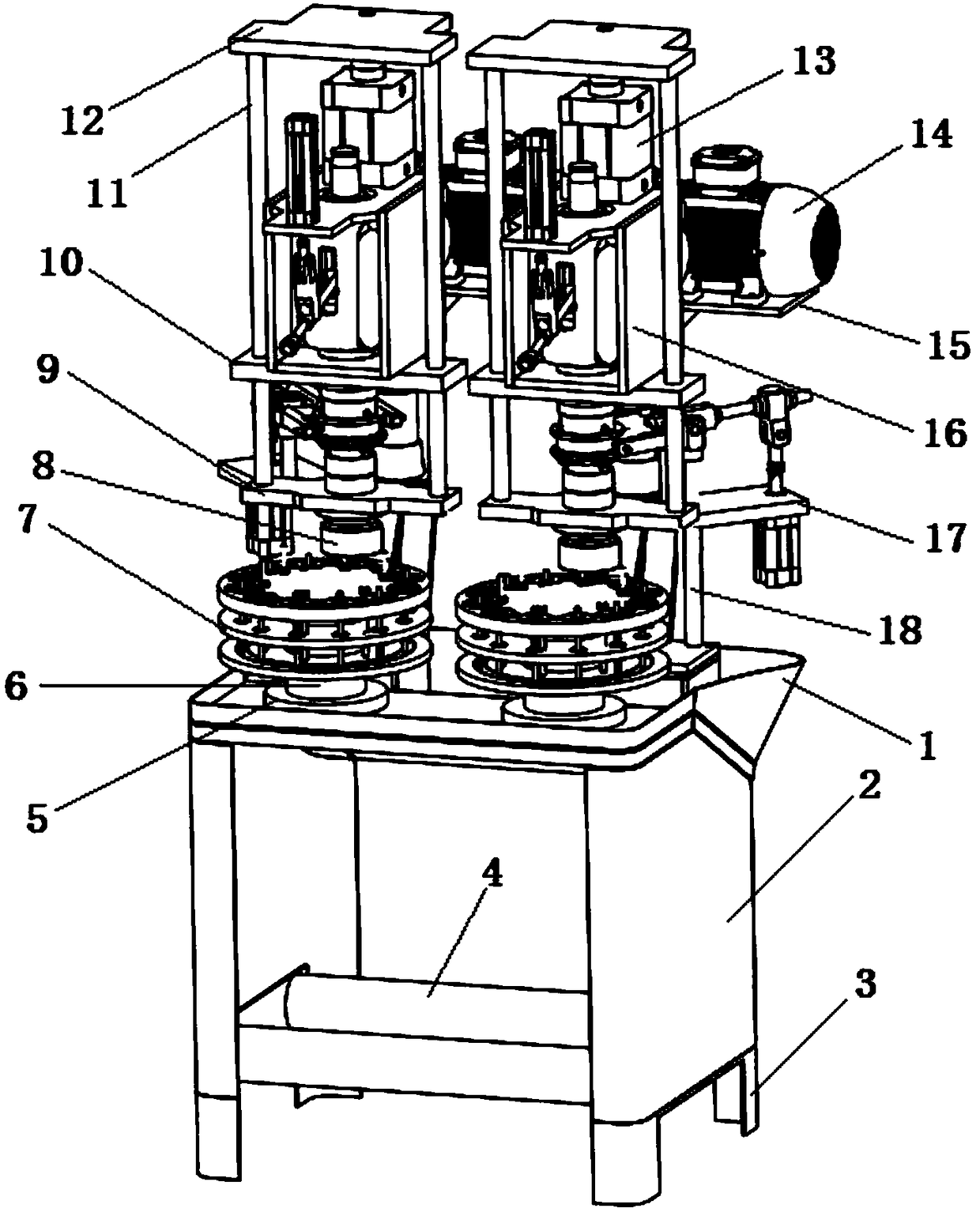

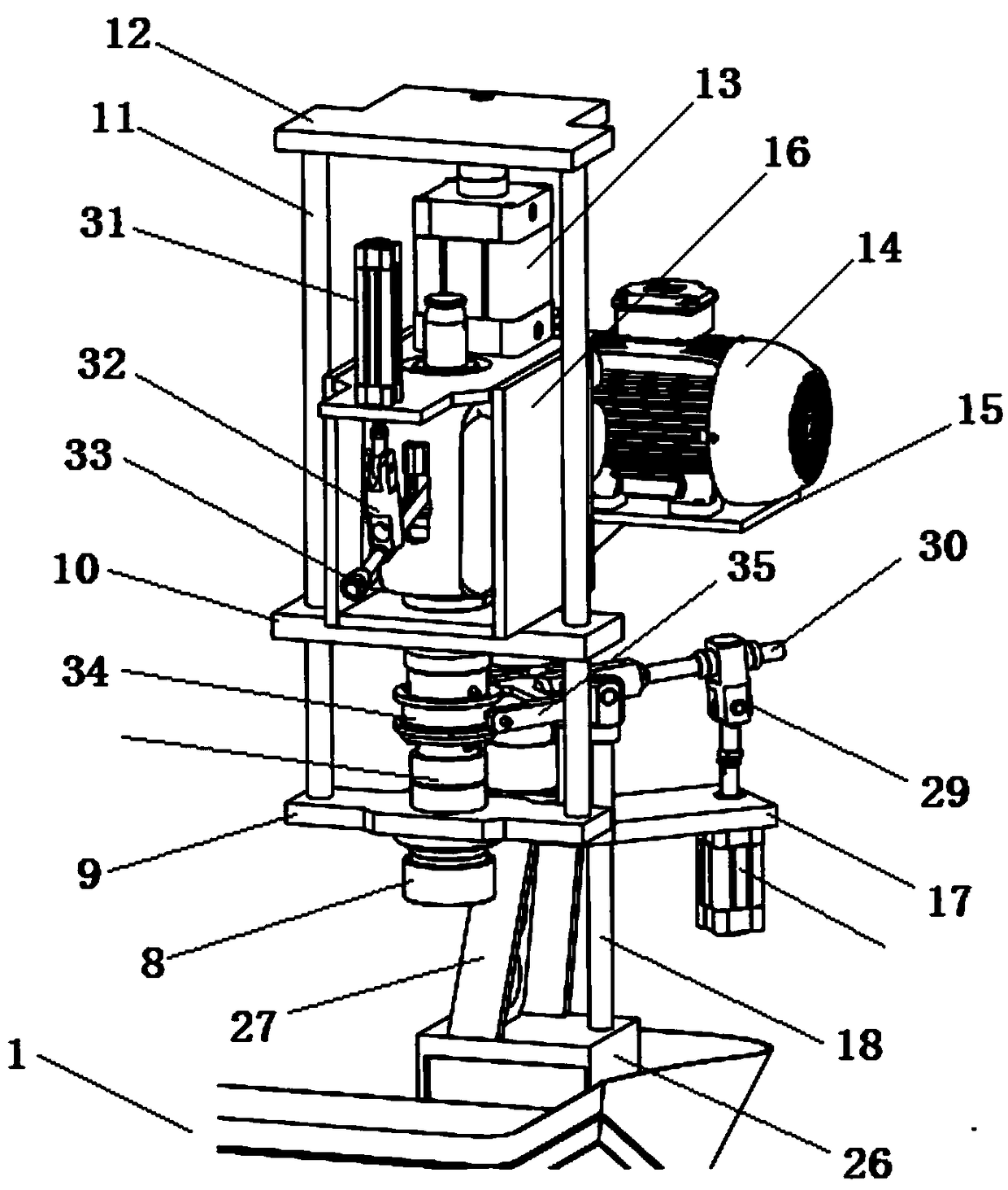

[0046] refer to Figure 1-10 As shown, an automatic drilling machine with double turntables and double drill floors includes a workbench 1, and the workbench 1 is provided with two identical drill floor mechanisms and two identical turntable mechanisms. The mechanism is arranged side by side at the rear of the upper plane of the workbench 1, and the two turntable mechanisms are respectively located directly in front of the two drill floor mechanisms;

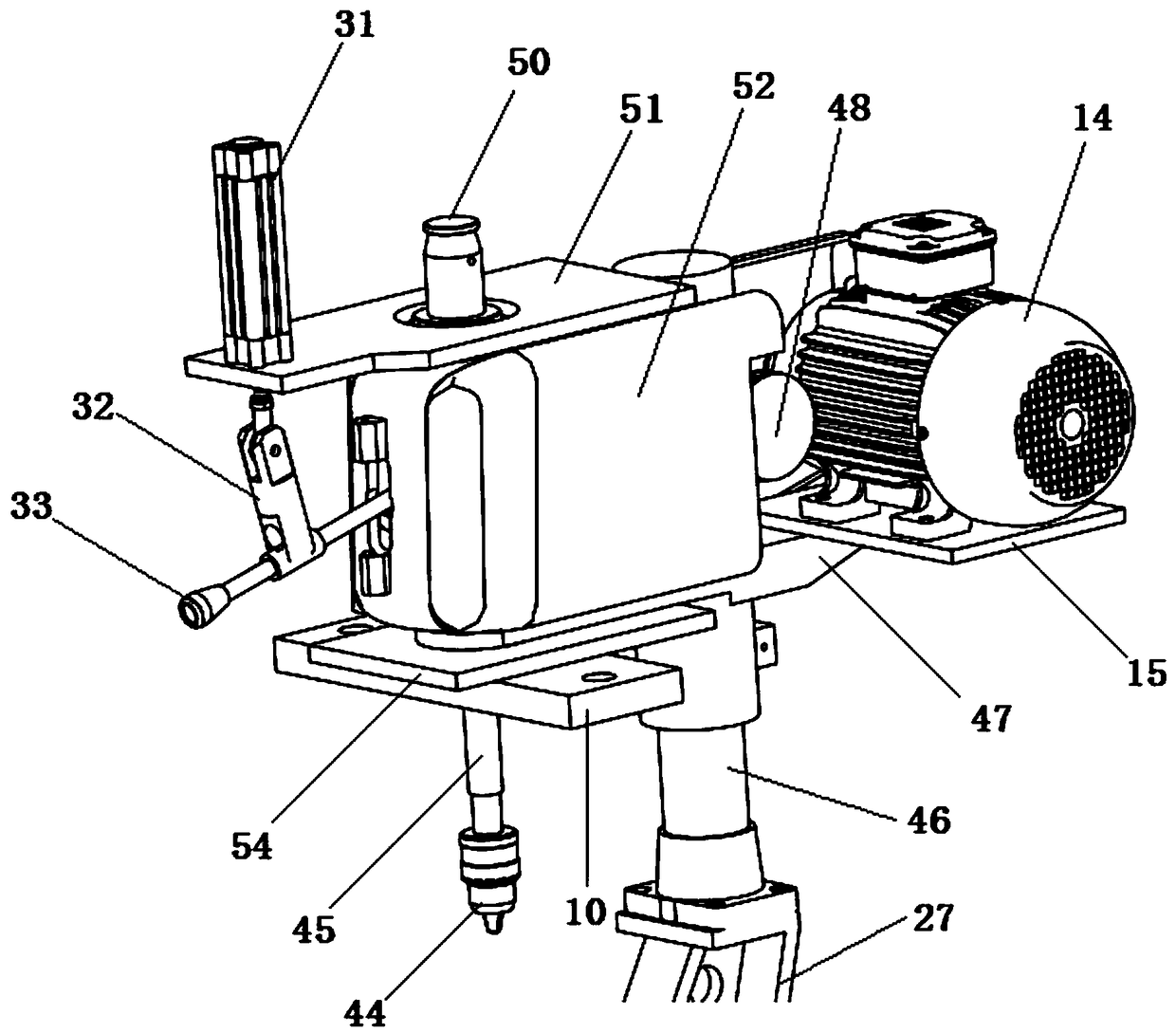

[0047] The drill floor mechanism includes a drill floor support 26 arranged on the rear part of the upper plane of the workbench 1. The drill floor support 26 is provided with a drill floor reinforcement rib 27, and the top of the drill floor reinforcement rib 27 is A drill floor column 46 that can be retracted up and down is provided; the top front portion of the drill floor column 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com