Large-area laser engraving method

A laser engraving and large-format technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of equipment service life impact, product quality, and low production efficiency, so as to improve equipment service life and reduce splicing Traces, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] With reference to accompanying drawing, the present invention is further elaborated in conjunction with following embodiment:

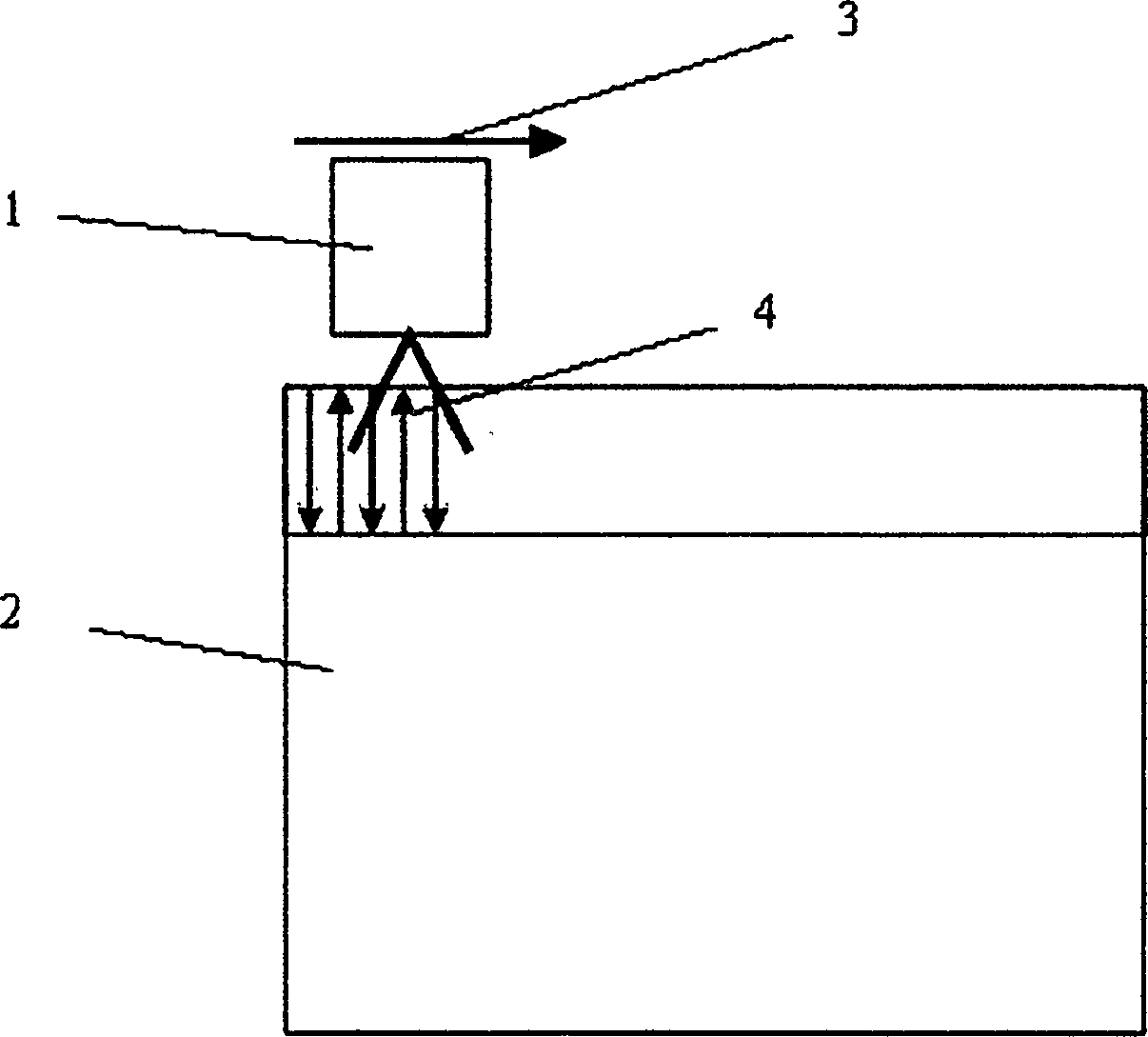

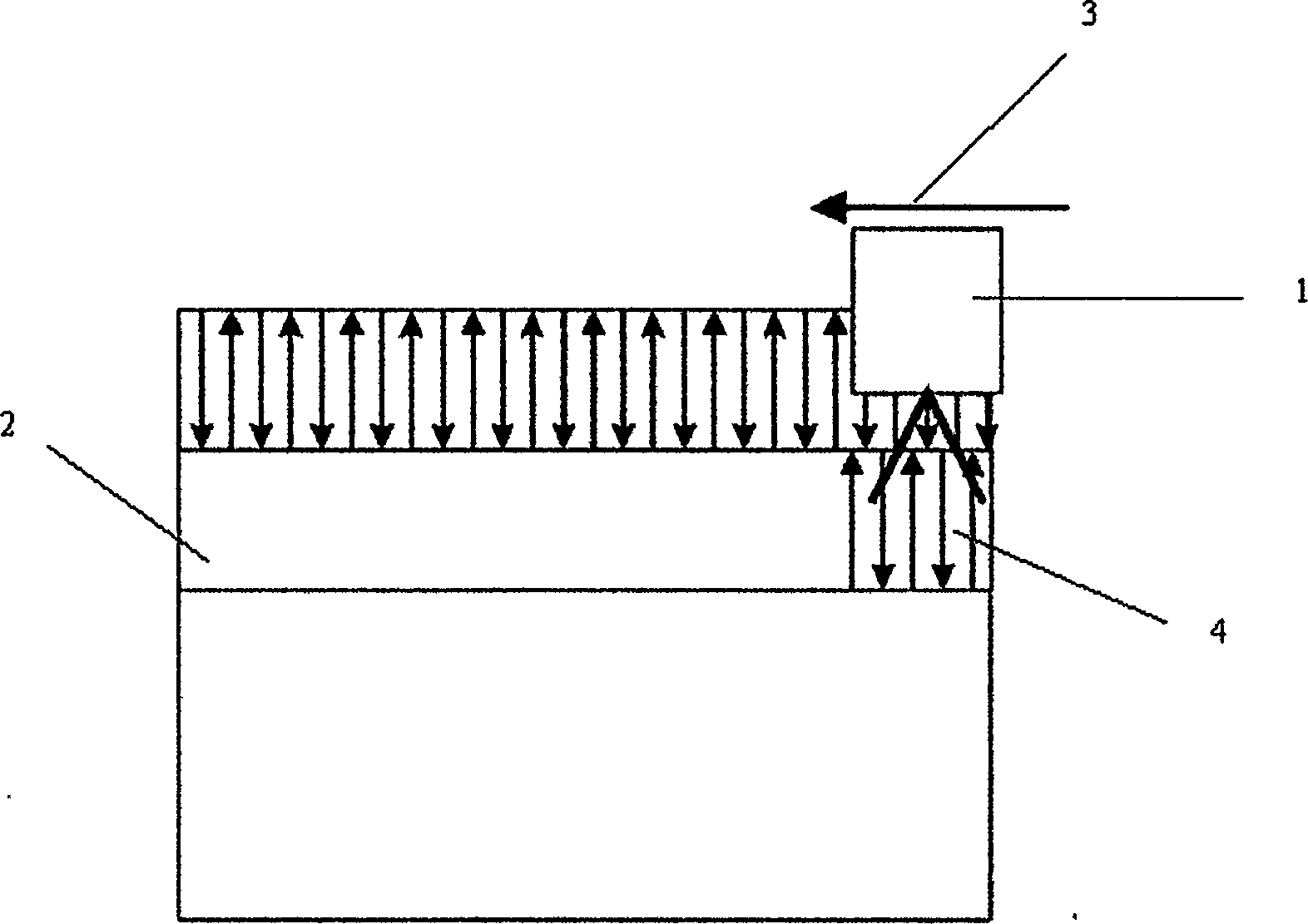

[0016] Such as figure 1 , 2 As shown, a method for large-scale laser engraving of the present invention comprises the following process steps:

[0017] Set the scanning amplitude and width of the vibrating mirror according to the amplitude of the large-scale picture to be laser engraved;

[0018] Make full use of the high-speed characteristics of the galvanometer scanner, and set the continuous scanning and engraving within the effective working range of the galvanometer from one direction;

[0019] The vibrating mirror moves forward continuously under the control of the platform, thus forming an engraving area covering a whole line, and then scans and engraves the next line until the entire graphic scanning and engraving ends;

[0020] When the galvanometer is scanning the engraved graphics, it has been continuously moving relative to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com