Manufacturing method of seamless three-dimensional fabric capable of colorful printing

A manufacturing method and seamless technology, which can be used in household components, household appliances, other household appliances, etc., and can solve problems such as falling off, affecting the productivity of product lines, and skewed seams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

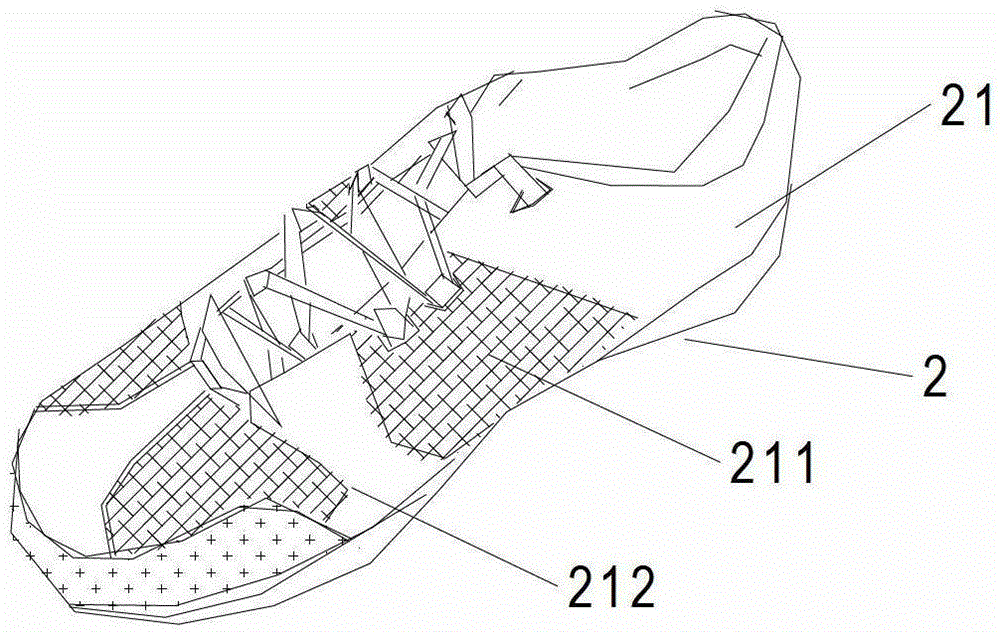

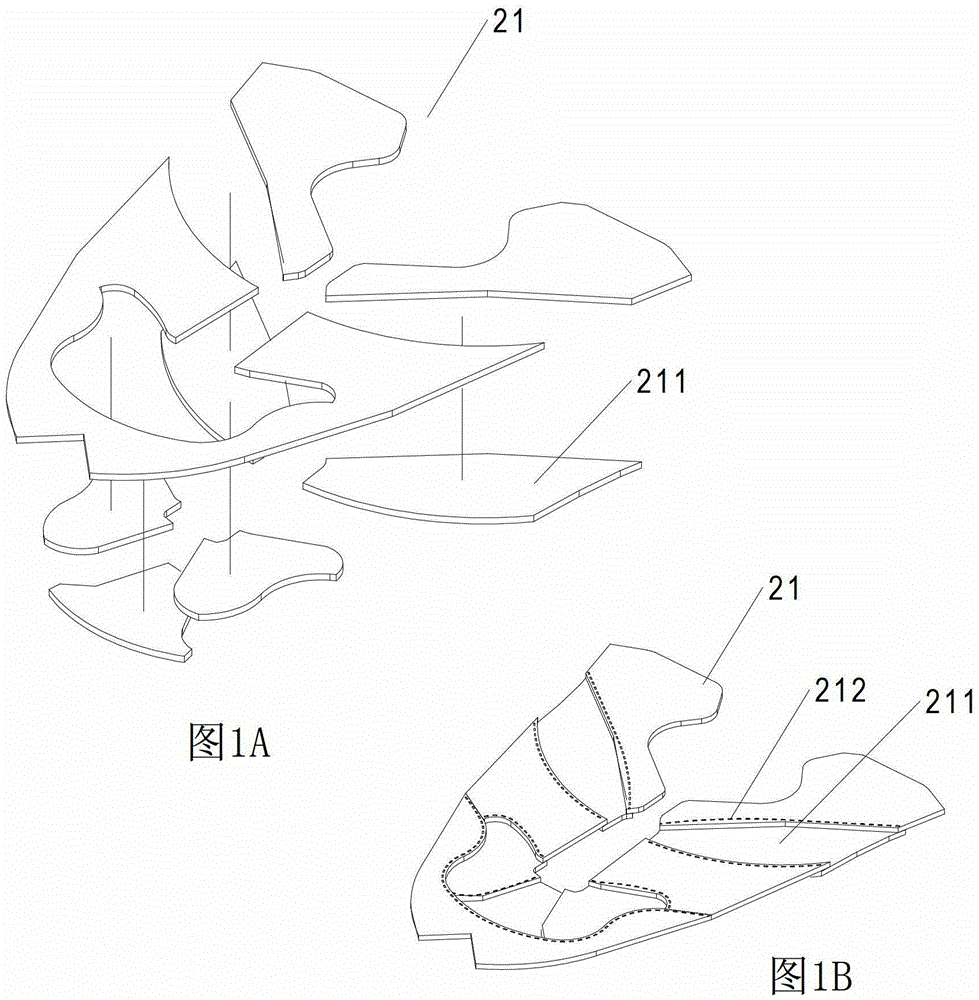

[0036] Please refer to figure 1 , Figure 1A and figure 2 As shown: a specific embodiment of the present invention includes a shoe body 2, a solid sheet-like block 211, and a vamp 21 made by stitching or pasting with solid sutures 212, so that the original size can be directly remade into a fixed mold. , to achieve the convenient and accurate manufacturing method of fabrics for shoes or other purposes that can be conveniently and accurately manufactured with the required three-dimensional surface shape and pattern distribution.

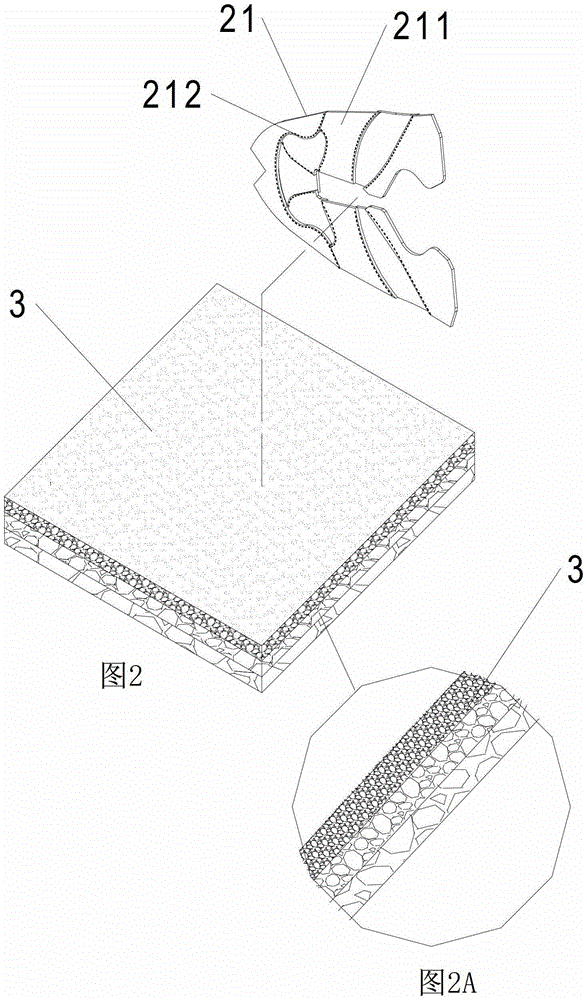

[0037] Please refer to figure 2 and Figure 2A As shown: the setting mold according to the present invention is formed by laminating multiple layers of mold powder with a thicker bottom layer and a finer surface layer in advance to form the bottom mold base 3 to be formed; wherein the mold powder is preferably ceramic powder.

[0038] After the top side of the surface layer of the bottom mold base 3 is back-pressed by the solid vamp 21, it will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com