New detachable direct connection horizontal single-stage pump

A single-stage pump, direct-connected technology, used in non-variable-capacity pumps, pumps, pump components, etc., can solve the problems of difficult disassembly and movement, increased maintenance time and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

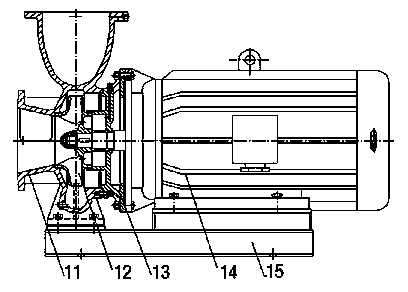

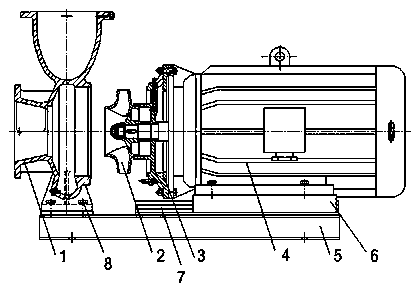

[0010] figure 2 It is composed of three parts: pump, extended shaft motor and base. It is characterized in that: the pump includes pump body, impeller, pump cover, and mechanical seal. The part of the base where the extended shaft motor is installed is provided with dovetail groove sliding guides, and the pump body is fixed by bolts. At one end of the base, a dovetail groove is arranged at the bottom of the extended shaft motor, and the dovetail groove at the bottom of the extended shaft motor is installed in the dovetail groove sliding guide rail on the base. The impeller, pump cover, mechanical seal and extended shaft motor are assembled as an integral part.

[0011] Since the pump body is a single component fixed on the base by bolts, the impeller, pump cover, mechanical seal and extension shaft motor are assembled as an integral part and installed on the sliding guide rail of the dovetail groove, so that the impeller, pump cover, mechanical seal and extension shaft The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com