Cluster Vacuum Bonding System

A vacuum, integrated technology, applied in the direction of connecting components, mechanical equipment, conveyor objects, etc., can solve the problems of inconsistent transmission requirements, vacuum adsorption force affecting system stability, structural pulling and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

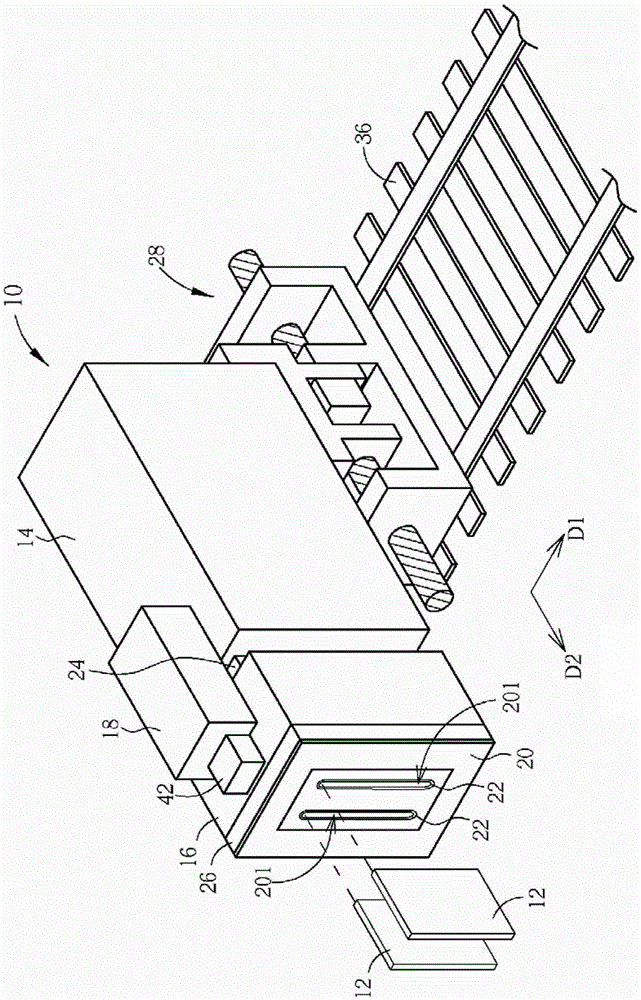

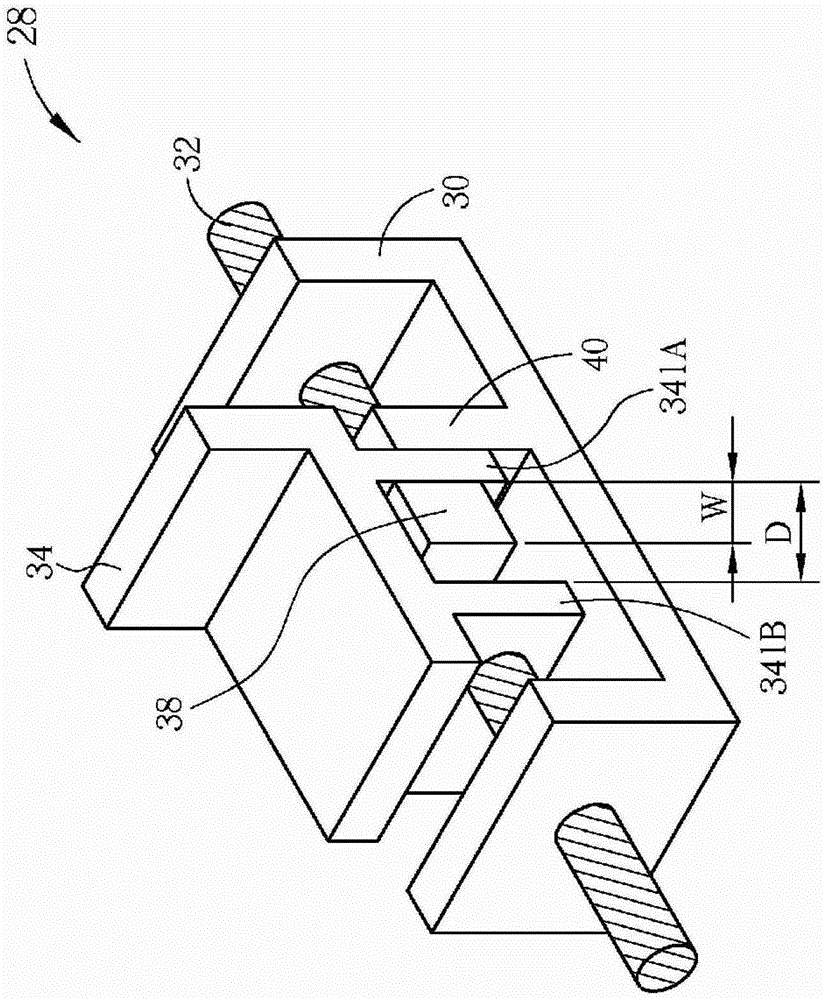

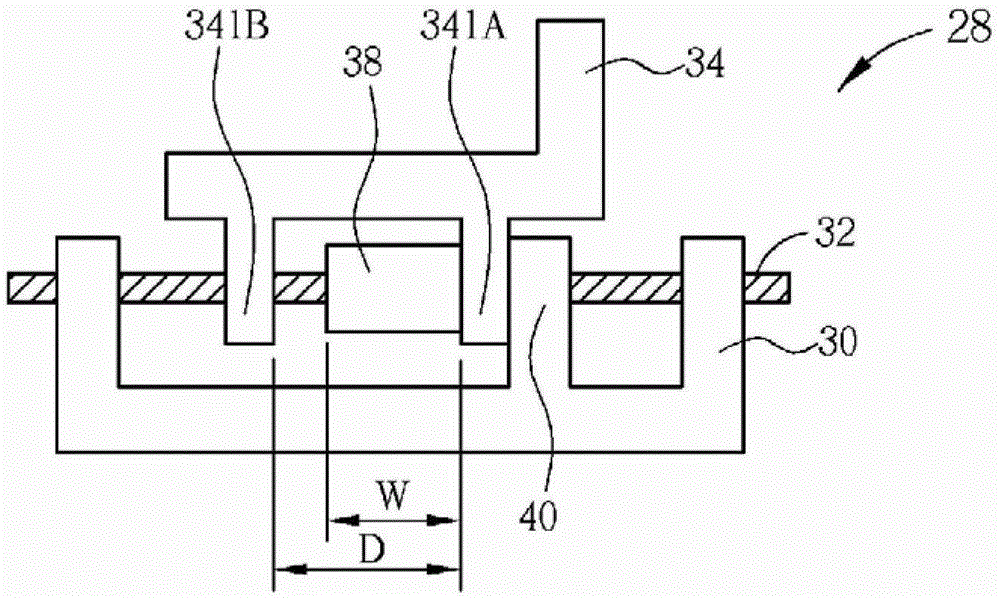

[0044] Such as figure 1 as shown, figure 1 It is a schematic diagram of a cluster vacuum bonding system 10 according to an embodiment of the present application. The cluster vacuum bonding system 10 is a bulky device capable of performing coating and other processes on multiple substrates 12 at the same time. The cluster vacuum bonding system 10 includes a transfer cavity 14 , at least one bonding neck 16 , an adjustment mechanism 18 , a sealing sheet 20 and a sealing gasket 22 . The chamber 14 is a closed / airtight conveying chamber, and the equipment required for the conveying device is arranged inside it. The transfer chamber 14 is used to transport the substrate to other chambers of the cluster vacuum bonding system 10 (it is a process chamber and is not shown in figure 1 middle). The transfer chamber 14 has at least one flange 24 for aligning with other chambers for connection. The joint neck 16 can be optionally made of metal, and the joint neck 16 is disposed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com