Fruit drying and separation device

A separation device and drying technology, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of inconvenient operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

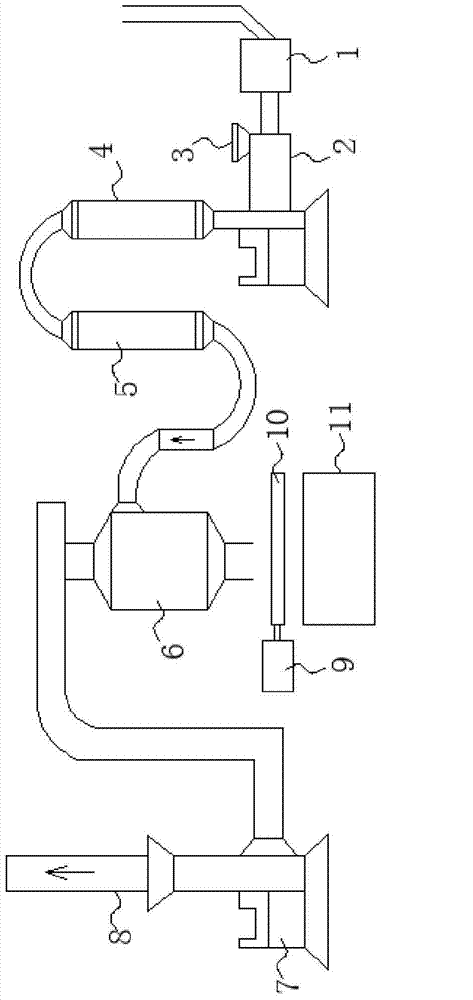

[0012] Such as figure 1 As shown, the fruit drying and separating device of the present invention includes a hot blast stove 1, and the hot blast stove 1 communicates with the feed pipe 2, and the feed pipe 2 is provided with a feed port 3, so that freshly picked fruits can be passed through the feed port 3 into the feed tube 3. The feed pipe 2 is connected to one end of the drying mechanism, the other end of the drying mechanism is connected to a separator 6, and the top of the separator 6 is connected to an exhaust fan 7, and the exhaust fan 7 is provided with an air outlet pipe 8 ; The bottom of the separator 6 is provided with a vibrating screening mechanism.

[0013] Further, the drying mechanism includes an upper drying pipe 4 and a lower drying pipe 5, the upper drying pipe 4 and the lower drying pipe 5 are connected through an arc bend, and the other end of the upper drying pipe is connected to the feed pipe 2 The other end of the lower drying pipe is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com