Self-disinfecting device for large-scale stainless steel water dispenser and disinfection process thereof

A disinfection device, stainless steel technology, applied in beverage preparation devices, household utensils, heating, etc., can solve the problems of drinking water personnel getting sick, low filtration efficiency, low sterilization cost, etc., achieve convenient maintenance and management in the later stage, and avoid personnel touch The effect of burns and simple device installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

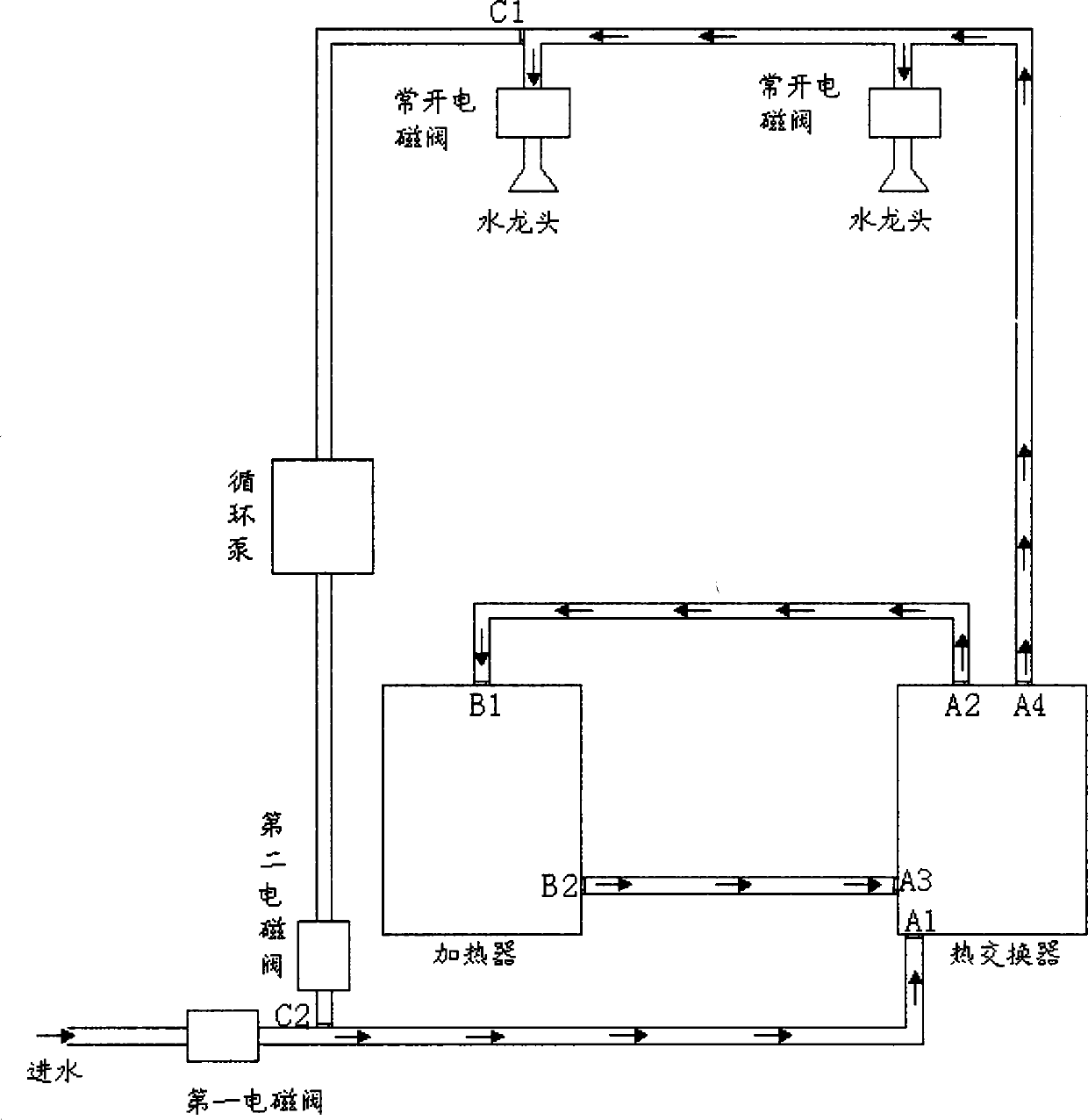

[0026] The solenoid valve is automatically controlled, the first solenoid valve and the normally open solenoid valve are closed, the second solenoid valve is opened, so that a closed loop is formed between each device and the water pipe, and the circulation pump is turned on, so that the pure water begins to be circulated, and the pure water in the water inlet pipe reaches the medium. The water is transported to the heater for heat treatment, and the purified water after heat treatment is transported to the heat exchanger, so that the water temperature of each pipe in the heat exchanger is at least 80°C, and the hot water treated by the heat exchanger is transported to the outlet pipe, Pasteurize the outlet pipe, transfer the hot water in the outlet pipe to the water inlet pipe, and pasteurize the water inlet pipe. The cycle sterilization time is at least 2 minutes. The valve is opened, and the second solenoid valve is closed, so that the hot water in the circulation circuit is...

Embodiment 2

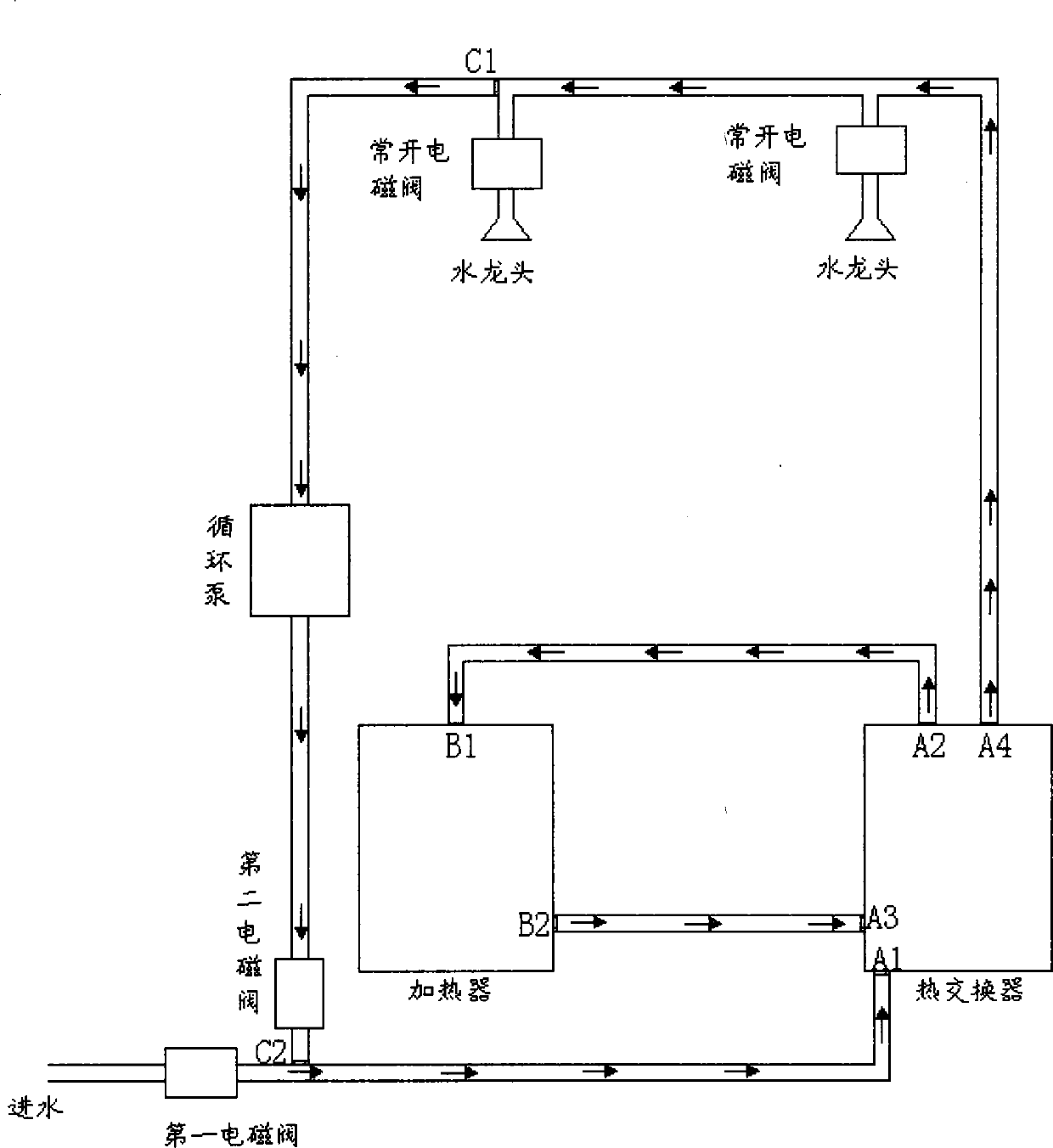

[0029] Manually control the solenoid valve, close the first solenoid valve and the normally open solenoid valve, and open the second solenoid valve to form a closed loop between each device and the water pipe, and turn on the circulation pump to start the circulation of pure water. The purified water is delivered to the heater for heat treatment, and the heated purified water is delivered to the heat exchanger, so that the water temperature of each pipe in the heat exchanger is at least 80°C, and the hot water treated by the heat exchanger is delivered to the outlet water Pipeline, pasteurize the outlet pipe, transport the hot water in the outlet pipe to the water inlet pipe, and pasteurize the water inlet pipe. The cycle sterilization time is at least 2 minutes, open the normally open solenoid valve, and disinfect the faucet. After the cycle disinfection is finished, the first solenoid valve and the normally open solenoid valve are opened, and the second solenoid valve is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com