Continuous conveying type circular waveguide microwave reactor

A microwave reactor, circular waveguide technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical/physical-chemical processes of applying energy, etc., can solve problems such as inability to achieve effects, and achieve reaction efficiency. The effect of increasing and reducing the demand for output power and improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

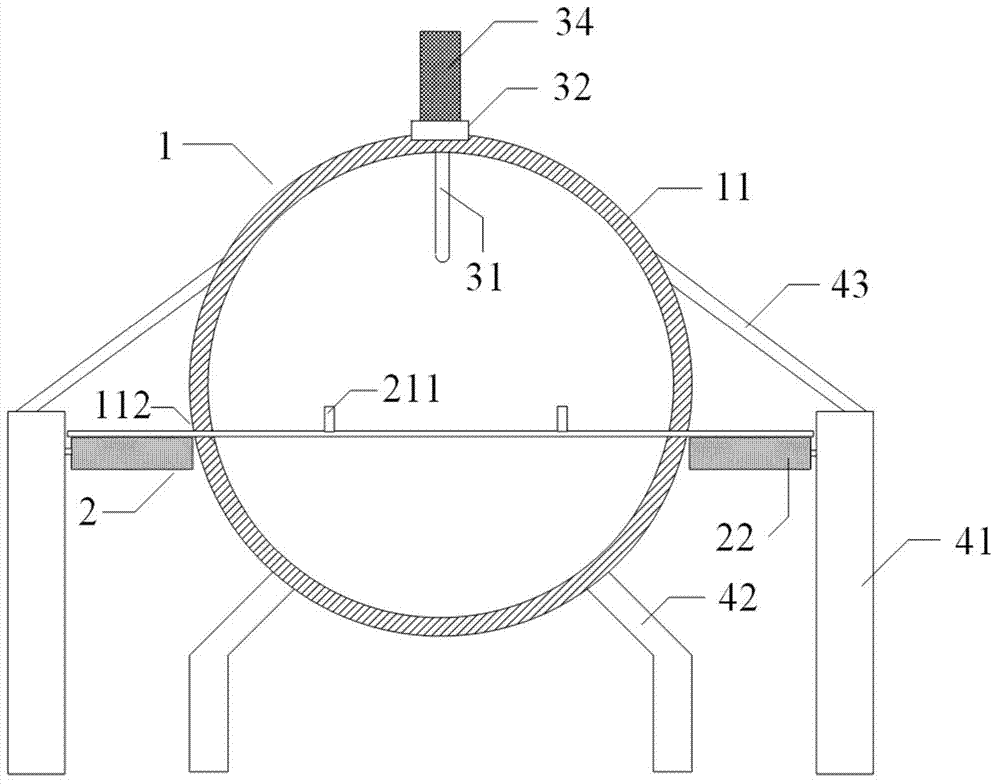

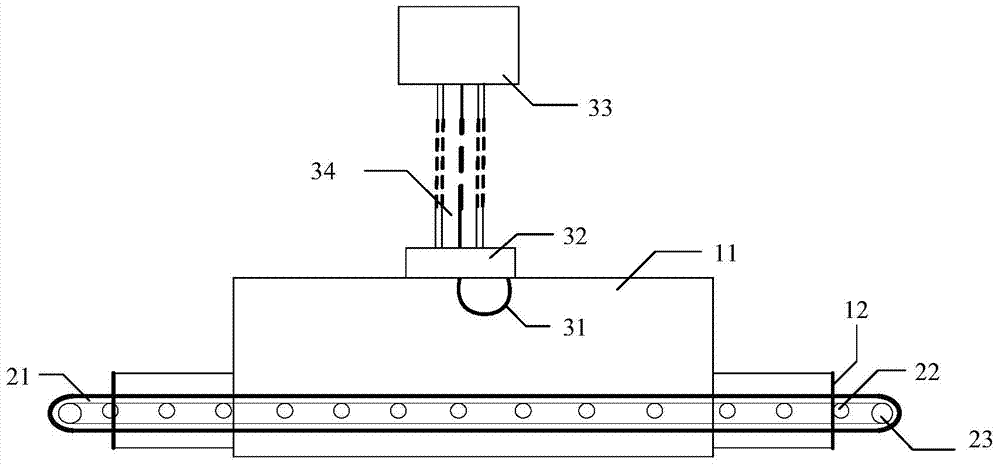

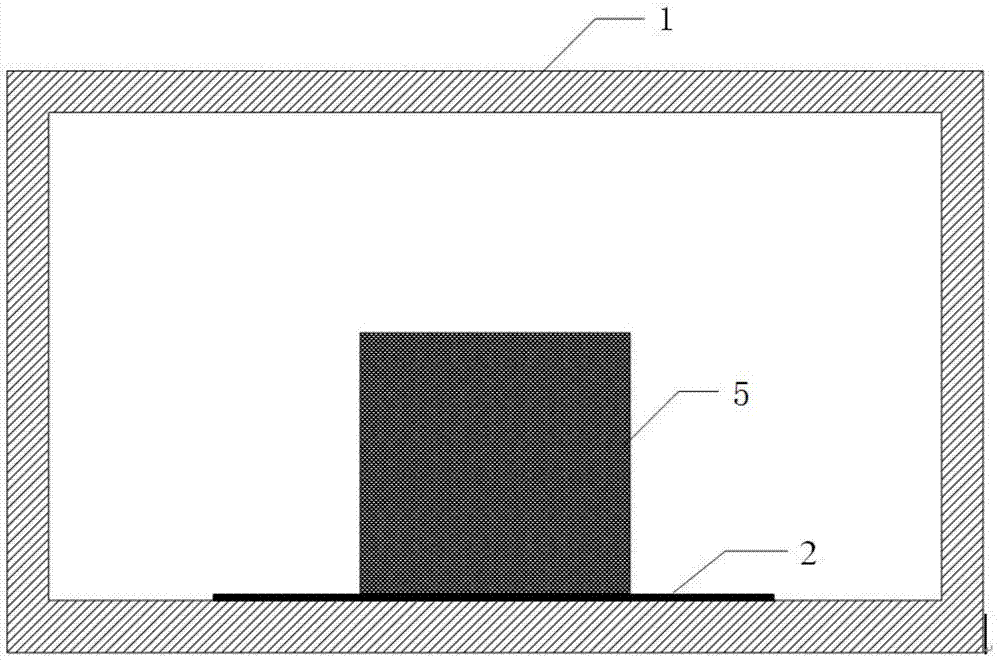

[0024] Embodiment 1: A traveling wave microwave reactor, including a reaction device 1 , a transmission device 2 , a power feeding device 3 , and a support device 4 . It is characterized in that the reaction device 1 is composed of an outer conductor 11 and an anti-leakage device 12, the outer conductor 11 is a cylindrical metal cavity, one end of the metal cavity is provided with a material inlet, and the other end is correspondingly equipped with a material outlet, and the metal cavity is located on the A narrow slit 112 is formed on both sides of the longitudinal axis of the cross section and runs through the whole along the axis. The narrow slit runs through the feed inlet, the side wall of the metal cavity, and the discharge outlet. The width of the slit is not greater than 20mm. Open a feeding circular hole at an appropriate position on the top or bottom of the longitudinal axis of the cross-section of the outer conductor 11; The conveyor belt 21 passes through the slit ...

Embodiment 2

[0031] Embodiment 2: On the basis of Embodiment 1, the length of the outer conductor 11 is changed to 2m, the center of the coupling ring 31 in the feeder 3 is 1m away from the end face of the outer conductor 11, and the radius of the coupling ring 31 is adjusted to 90.89mm.

Embodiment 3

[0032] Embodiment 3: On the basis of Embodiment 1, the cut-off waveguide is replaced by a C14 standard circular waveguide with an inner surface radius of 78.50 mm. The center of circle of the circular waveguide coincides with the center of circle of the outer conductor 11, and two symmetrical slits are opened at the corresponding positions of the side wall of the circular waveguide and the outer conductor 11 so that the conveyor belt 21 can pass through the middle. This example makes it possible to process items such as square cross-sections (or other cross-sections) with a side length of 50-90 mm, which greatly expands the scope of application of the reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com