Separated double-layer rotary drum spiral screening device and method

A spiral sieve and separation technology, which is applied to the screening of strip materials and the field of screening devices after straw pulverization, can solve the problems of not overcoming the rotational speed of the trommel screen, the difficulty of screening straw materials, and the inability to independently control the rotational speed, etc. High screening efficiency, good adaptability and easy bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

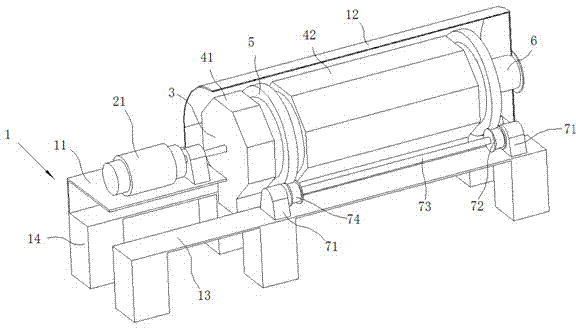

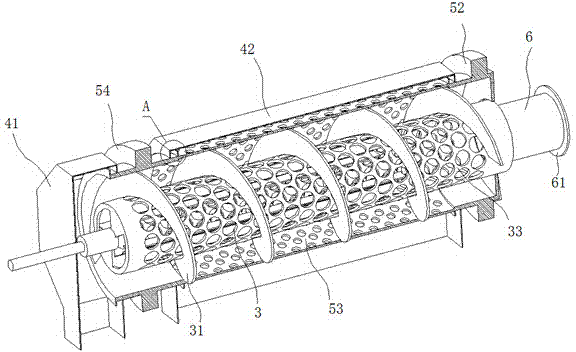

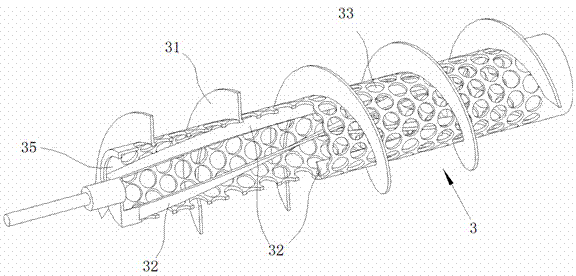

[0041] Such as figure 1 and figure 2 As shown, the device of the present invention is composed of an inner layer sieve cylinder 3, an outer layer sieve cylinder 5, a long material collection shell 41, a short material collection shell 42 and a support 1, and the inner layer sieve cylinder 3 is coaxially installed on the outer layer sieve cylinder 5 Inside, the inner sieve cylinder 3 and the outer sieve cylinder are independently driven by motors installed on the bracket 1.

[0042] Such as figure 1 As shown, the support 1 includes a support column 14 at the bottom and a support plate 13 above it, the support plate 13 is connected with a motor mounting frame 11, and the motor mounting frame 11 is equipped with a main drive motor connected to the inner screen cylinder 3 21. The shell 12 is connected to the su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap