Ball vibrating screening device and ball feeder

A vibrating screening and steel ball technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of ball jamming and achieve the effect of high degree of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

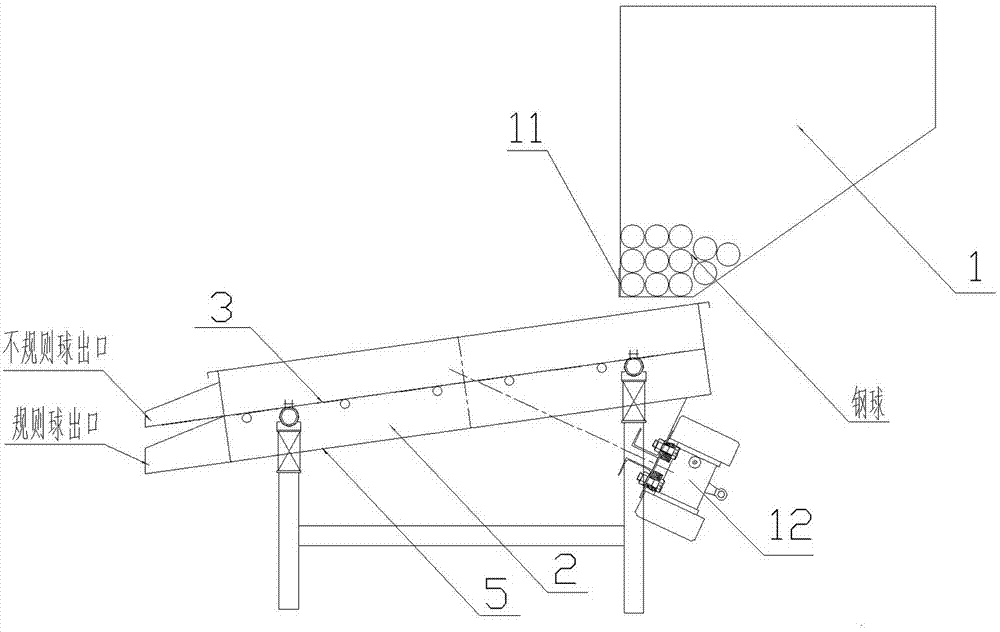

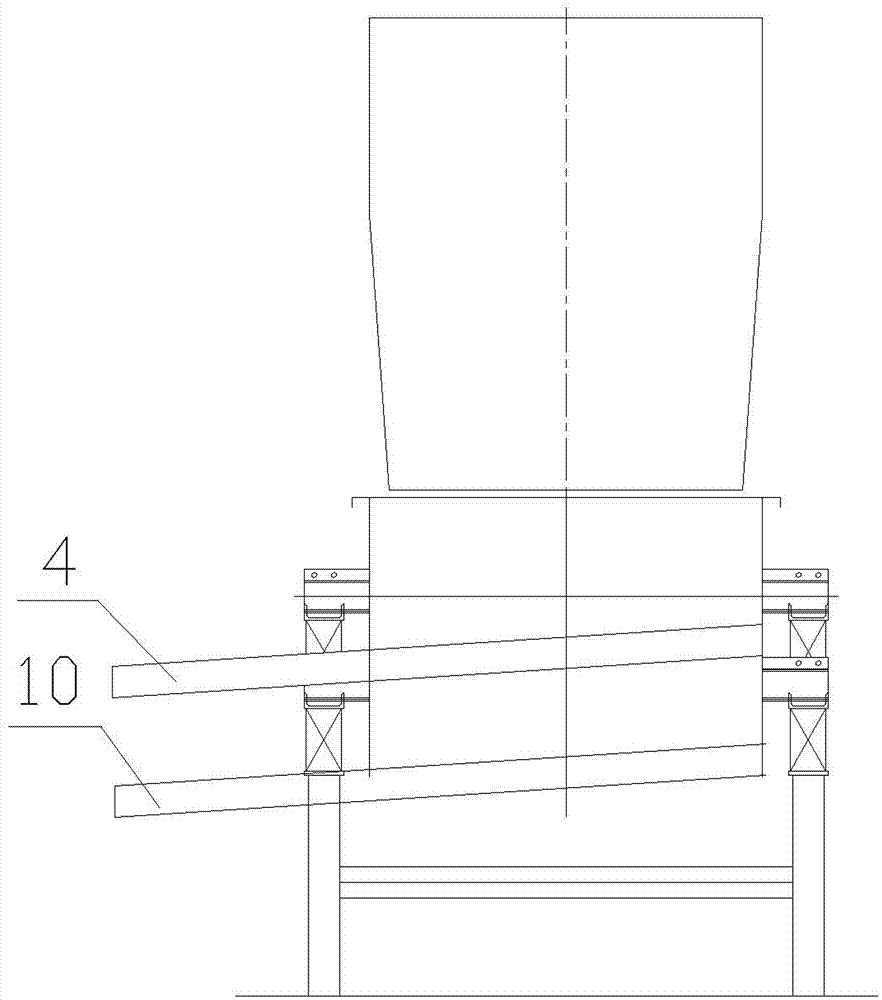

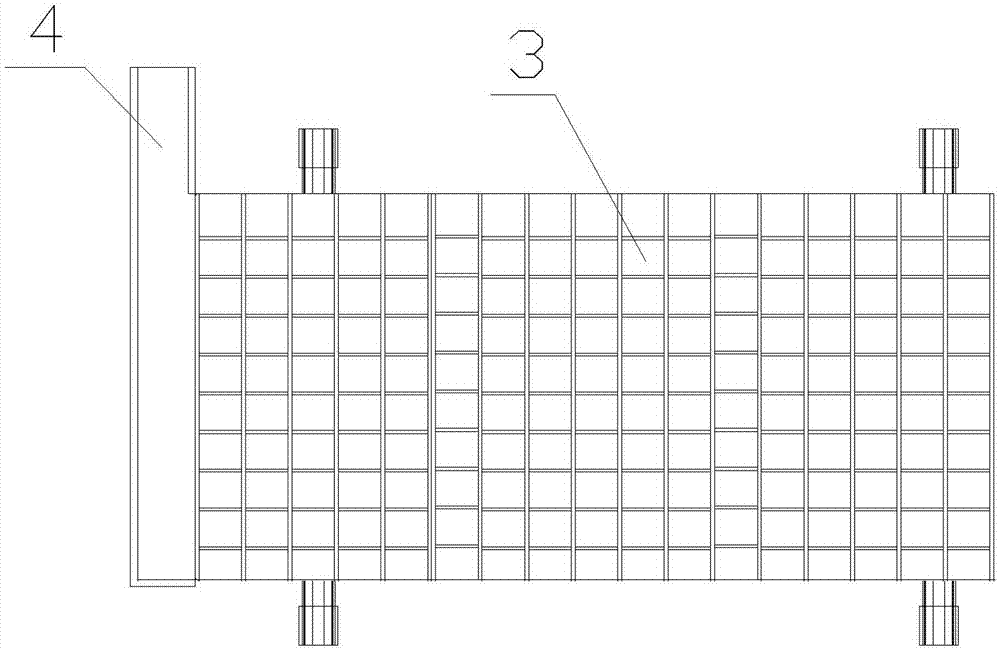

[0024] Such as Figure 1~4 As shown, the steel ball vibrating screening device provided by the present invention includes an upper bin body and a lower bin body with the same inclination direction, a grid sieve 3 arranged at the junction of the upper bin body and the lower bin body, and a sieve arranged at the bottom of the lower bin body Bottom plate 5. Irregular ball chute 4 and regular ball chute 10 are arranged respectively at the end of upper bin body and lower bin body. The device is driven by a vibration motor 12 .

[0025] The grid hole size of the grid sieve 3 is slightly larger than the maximum diameter of the screened steel balls. Preferably, the 3 grid holes of the grid sieve are square, and the side length of the grid hole is slightly larger than the maximum diameter of the steel balls to be screened. As a further improvement, the grid sieve 3 is double-layered, and the two layers surround the middle bin body; the size of the upper layer of grid holes is slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com