Air circulation system of an inoculant granulation workshop

An air circulation system and production workshop technology, applied in the directions of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inoculant granulation that cannot be excluded in real time, affecting the health of workers and the normal operation of production equipment, etc. Guaranteed healthy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

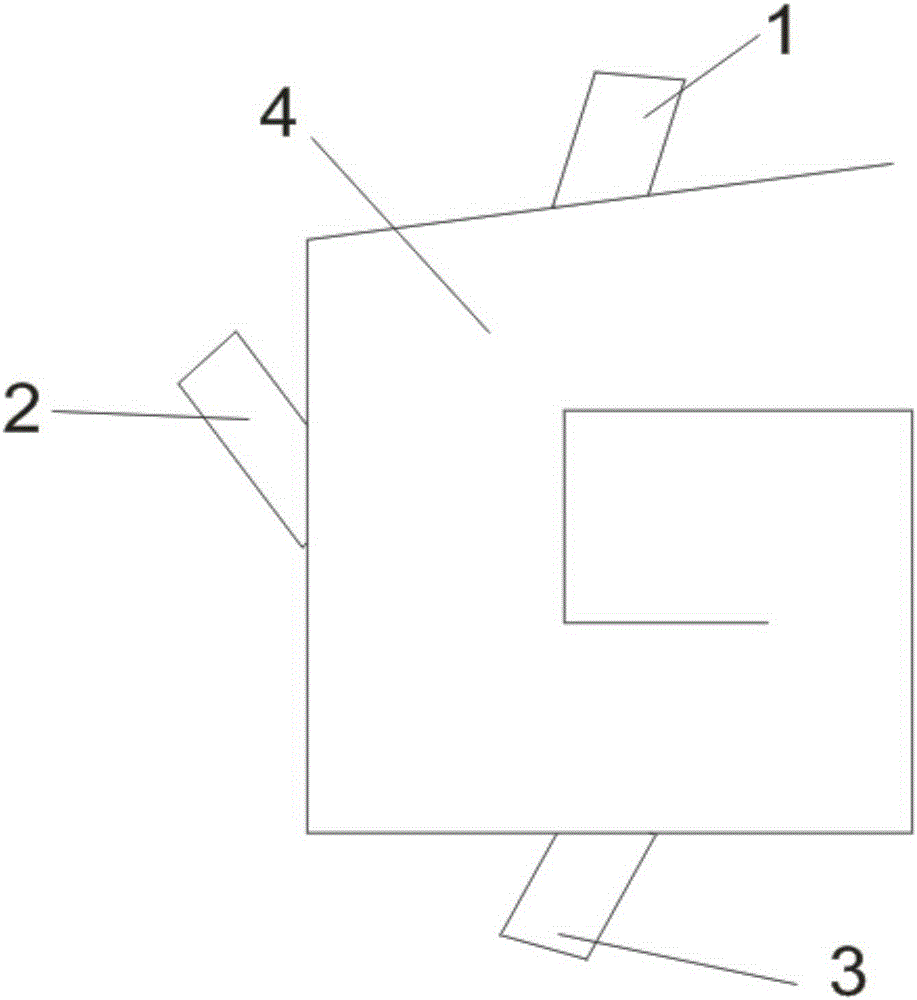

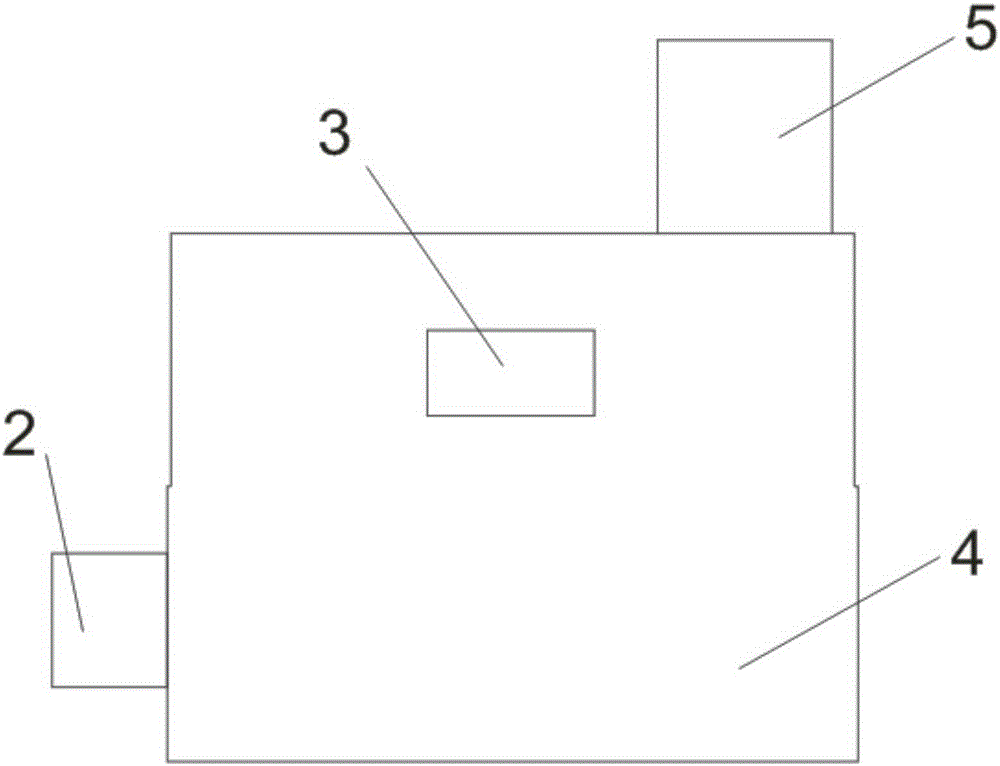

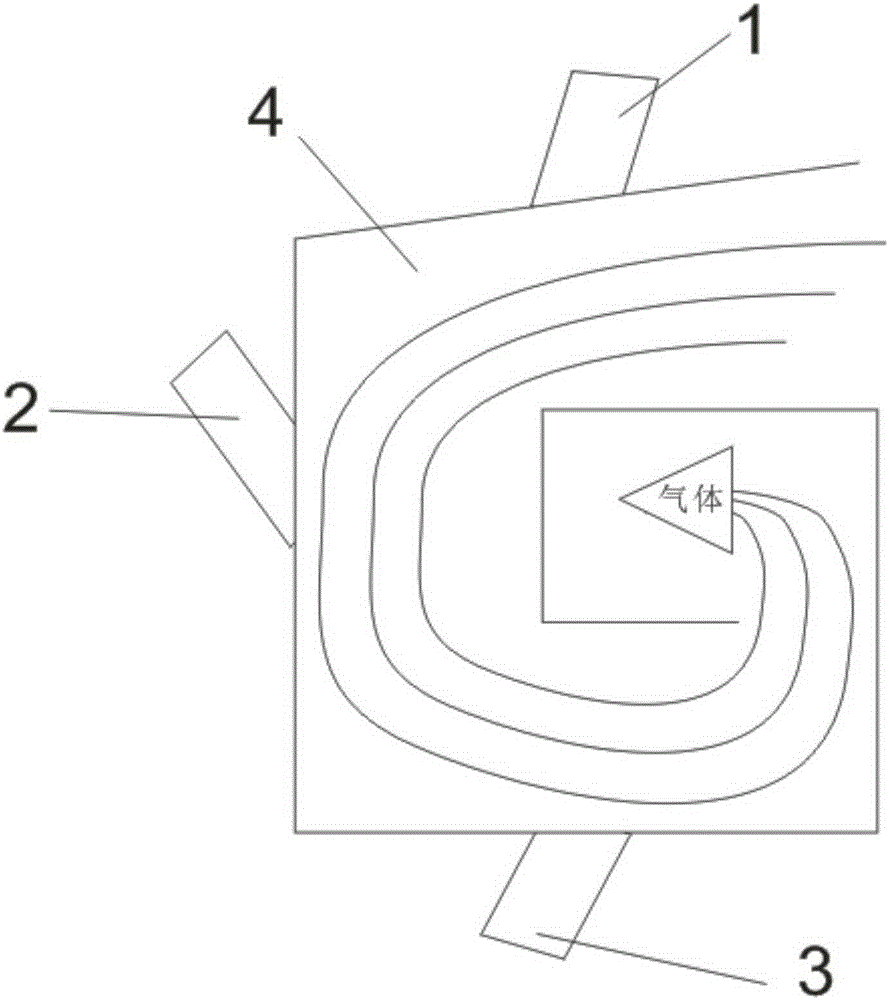

[0024] according to Figures 1 to 3 As shown, an air circulation system of an inoculant granulation production workshop includes I fan 1, II fan 2, III fan 3, workshop main body 4 and exhaust device 5; the workshop main body 4 is a spiral shape with one end open; the workshop The three walls of the main body 4 are provided with I fan 1, II fan 2 and III fan 3 respectively; the top of the closed end of the workshop main body 4 is provided with at least one exhaust device 5.

[0025] The preferred workshop main body 4 is designed as upper and lower layers, which is more conducive to the circulation of air.

[0026] The preferred I fan 1, II fan 2 and III fan 3 are centrifugal blowers. The centrifugal blower has good ventilation effect and no corrosion. It is dust-free and easy to maintain, which is more suitable for the use of the inoculant gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com