Rotary base for workpiece welding and utilization method of rotary base

A technology of rotating the base and workpiece, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of repeated welding of welds, repeated welding of welds, unstable motor rotation, etc., to reduce work load, ensure work stability, and reduce welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

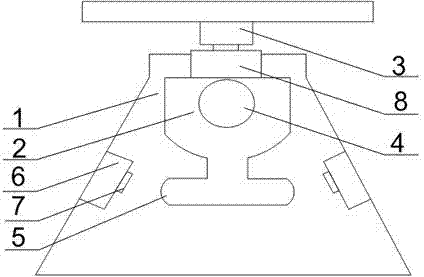

[0019] like Figure 1 to Figure 2 As shown, a workpiece welding rotating base of the present invention and its use method, the workpiece to be welded is fixed on the console 3, the motor 4 is started, the motor 4 drives the mounting seat to rotate, and then the workpiece welding position on the console 3 is changed, which is convenient Quickly weld the workpiece; the bottom of the rotary base 2 is connected with a T-shaped block 5, and the T-shaped block 5 cooperates with the limit blocks 6 at both ends of the support frame 1 to limit the rotation position of the rotary base 2. When the rotary base 2 When rotating clockwise, the T-shaped block 5 collides with the limit block 6 on the left end of the support frame 1. After the travel switch 7 on the limit block 6 contacts the left end of the T-shaped block 5, the travel switch 7 controls the motor 4 to stop rotating. When the slewing base 2 rotates counterclockwise, the T-shaped block 5 collides with the limit block 6 on the ri...

Embodiment 2

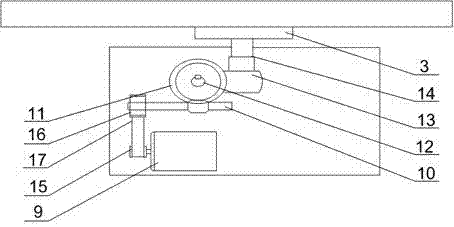

[0021] like figure 2 As shown, on the basis of Embodiment 1, the present embodiment includes a DC motor 9, a first worm 10, a first worm wheel 11 and a support rod 14, and the output end of the DC motor 9 is connected to the first worm 10 , the first worm wheel 11 cooperates with the first worm screw 10, the second worm screw 12 is arranged at the center of the first worm wheel 11, the second worm wheel 13 is installed at the lower end of the support rod 14, the upper end of the support rod 14 is connected with the bottom of the console 3, the second Two worm gears 13 cooperate with the second worm screw 12; A small pulley 15 is installed on the output end of the DC motor 9, and a large pulley 16 is installed on the first worm 10, and the small pulley 15 and the large pulley 16 Connected by belt 17. Considering the requirements of welding speed, the rotary speed of the console 3 is relatively small, so the reduction ratio required is relatively large, and in order to reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com