High-bending-resistance PU (polyurethane) shoe material and manufacturing method thereof

A technology of high folding resistance and shoe material, applied in the direction of sole, footwear, application, etc., can solve the problems of unsatisfactory folding resistance and easy fracture, and achieve the effect of improving tensile strength and good folding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

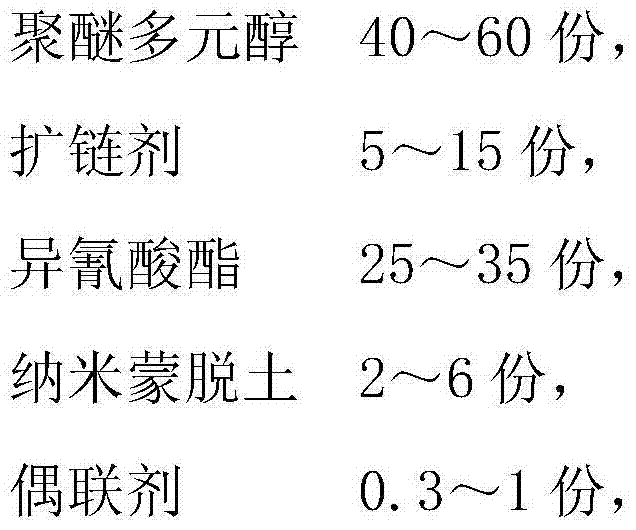

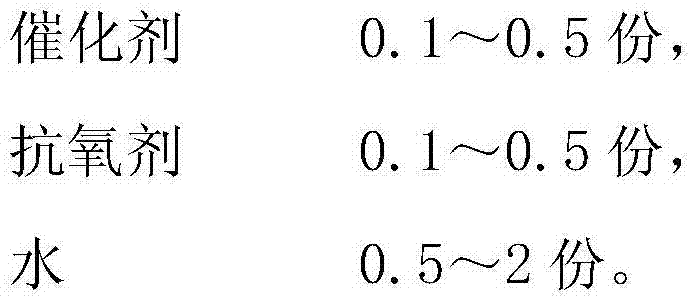

[0024] A kind of high folding-resistant PU shoe material, its parts by weight consist of:

[0025]

[0026] Its manufacturing method comprises the following steps:

[0027] (1) stirring and refluxing the nano-montmorillonite and the coupling agent, washing with acetone, filtering, drying under vacuum conditions, and grinding to obtain the modified nano-montmorillonite;

[0028] (2) baking and drying polyether polyol and isocyanate respectively, for subsequent use;

[0029] (3) Add other components in the formula and the modified nano-montmorillonite obtained in the step (1) to the polyether polyol after drying, and mix uniformly to form a mixture;

[0030] (4) mixing the mixture obtained in step (3) with the dried isocyanate and casting to obtain a high folding-resistant PU shoe material.

Embodiment 2

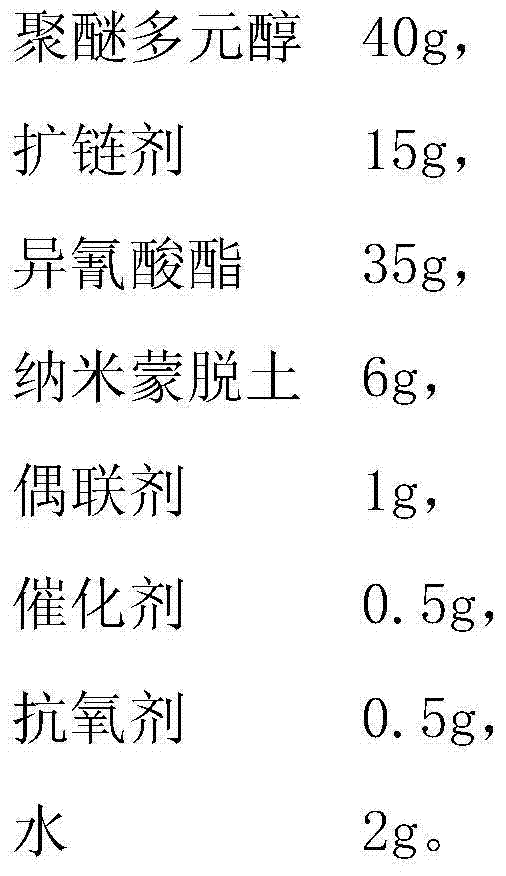

[0032] A kind of high folding-resistant PU shoe material, its parts by weight consist of:

[0033]

[0034] Its manufacturing method comprises the following steps:

[0035] (1) stirring and refluxing the nano-montmorillonite and the coupling agent, washing with acetone, filtering, drying under vacuum conditions, and grinding to obtain the modified nano-montmorillonite;

[0036] (2) baking and drying polyether polyol and isocyanate respectively, for subsequent use;

[0037] (3) Add other components in the formula and the modified nano-montmorillonite obtained in the step (1) to the polyether polyol after drying, and mix uniformly to form a mixture;

[0038] (4) mixing the mixture obtained in step (3) with the dried isocyanate and casting to obtain a high folding-resistant PU shoe material.

Embodiment 3

[0040] A kind of high folding-resistant PU shoe material, its parts by weight consist of:

[0041]

[0042]

[0043] Its manufacturing method comprises the following steps:

[0044] (1) stirring and refluxing the nano-montmorillonite and the coupling agent, washing with acetone, filtering, drying under vacuum conditions, and grinding to obtain the modified nano-montmorillonite;

[0045] (2) baking and drying polyether polyol and isocyanate respectively, for subsequent use;

[0046] (3) Add other components in the formula and the modified nano-montmorillonite obtained in the step (1) to the polyether polyol after drying, and mix uniformly to form a mixture;

[0047] (4) mixing the mixture obtained in step (3) with the dried isocyanate and casting to obtain a high folding-resistant PU shoe material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com