Ultralow-emission glass-fiber-reinforced polypropylene composite material and preparation method thereof

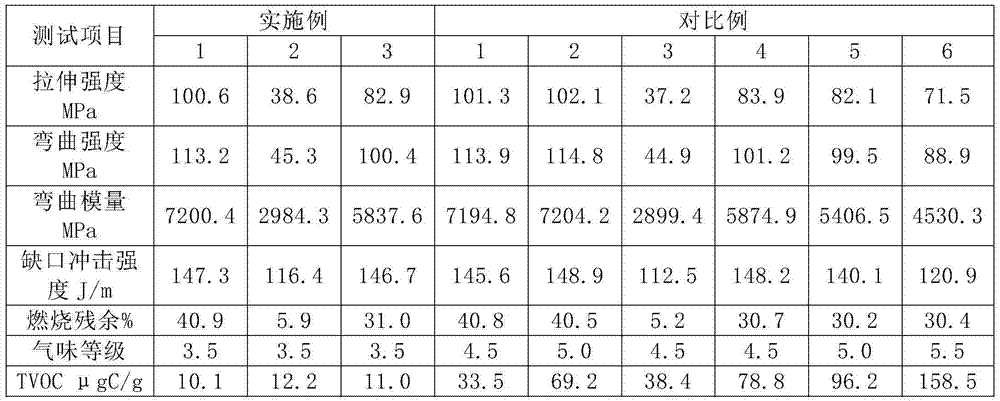

A composite material, polypropylene technology, applied in the field of ultra-low emission glass fiber reinforced polypropylene composite material and its preparation, can solve the problem of odor and VOC that cannot be fundamentally solved, and achieve excellent mechanical properties, low TVOC value, coloring Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

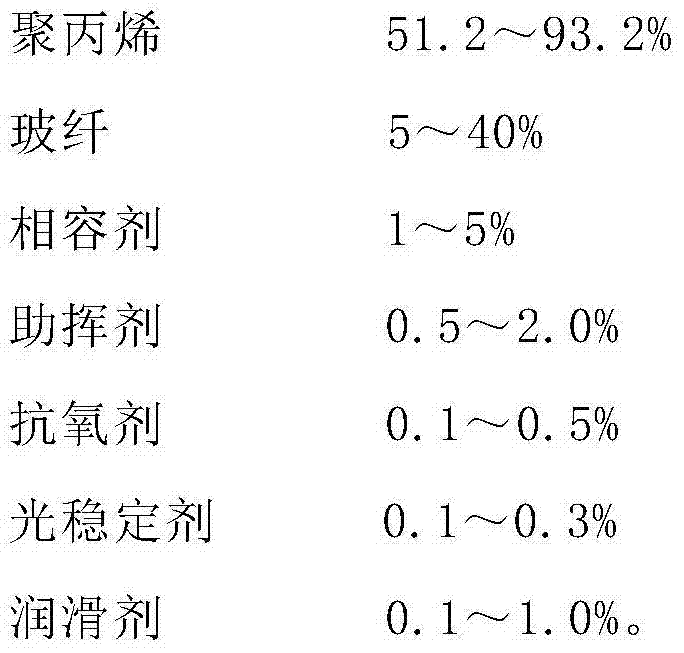

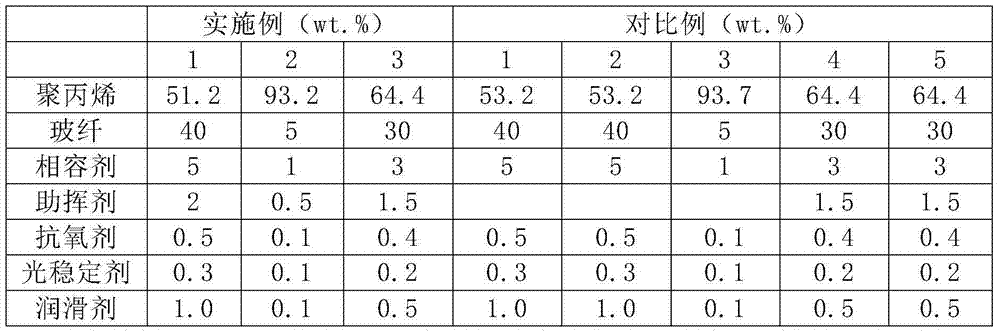

[0028] This example relates to an ultra-low emission glass fiber reinforced polypropylene composite material, and its components and dosage are shown in Table 1. The preparation of the ultra-low emission glass fiber reinforced polypropylene composite material of this embodiment specifically includes the following steps:

[0029] 1. Take the raw materials according to the weight percentage content shown in Table 1:

[0030] 2. Put the raw materials except the glass fiber and the volatilization aid into the high mixer and mix for 8 minutes, then add the volatilization aid and mix for 2 minutes, then discharge; then put the mixture into the twin-screw extruder to extrude and granulate , the glass fiber is added through the glass fiber port of the extruder during extrusion, and the content is controlled by the number of glass fiber strands and feeding parameters to obtain an ultra-low emission glass fiber reinforced polypropylene composite material. Among them, the process temper...

Embodiment 2

[0032] This example relates to an ultra-low emission glass fiber reinforced polypropylene composite material, and its components and dosage are shown in Table 1. The preparation of the ultra-low emission glass fiber reinforced polypropylene composite material of this embodiment specifically includes the following steps:

[0033] 1. Take the raw materials according to the weight percentage content shown in Table 1:

[0034]2. Put the raw materials except the glass fiber and the volatilization aid into the high mixer and mix for 8 minutes, then add the volatilization aid and mix for 2 minutes, then discharge; then put the mixture into the twin-screw extruder to extrude and granulate , the glass fiber is added through the glass fiber port of the extruder during extrusion, and the content is controlled by the number of glass fiber strands and feeding parameters to obtain an ultra-low emission glass fiber reinforced polypropylene composite material. Among them, the process tempera...

Embodiment 3

[0036] This example relates to an ultra-low emission glass fiber reinforced polypropylene composite material, and its components and dosage are shown in Table 1. The preparation of the ultra-low emission glass fiber reinforced polypropylene composite material of this embodiment specifically includes the following steps:

[0037] 1. Take the raw materials according to the weight percentage content shown in Table 1:

[0038] 2. Put the raw materials except the glass fiber and the volatilization aid into the high mixer and mix for 8 minutes, then add the volatilization aid and mix for 2 minutes, then discharge; then put the mixture into the twin-screw extruder to extrude and granulate , the glass fiber is added through the glass fiber port of the extruder during extrusion, and the content is controlled by the number of glass fiber strands and feeding parameters to obtain an ultra-low emission glass fiber reinforced polypropylene composite material. Among them, the process temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com