Method for constructing small-radius curve ballastless track

A small radius curve, ballastless track technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of complex construction, difficult to ensure accuracy, affecting construction and other problems, achieve good roundness, simple and reliable adjustment, and solve the adjustment. difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

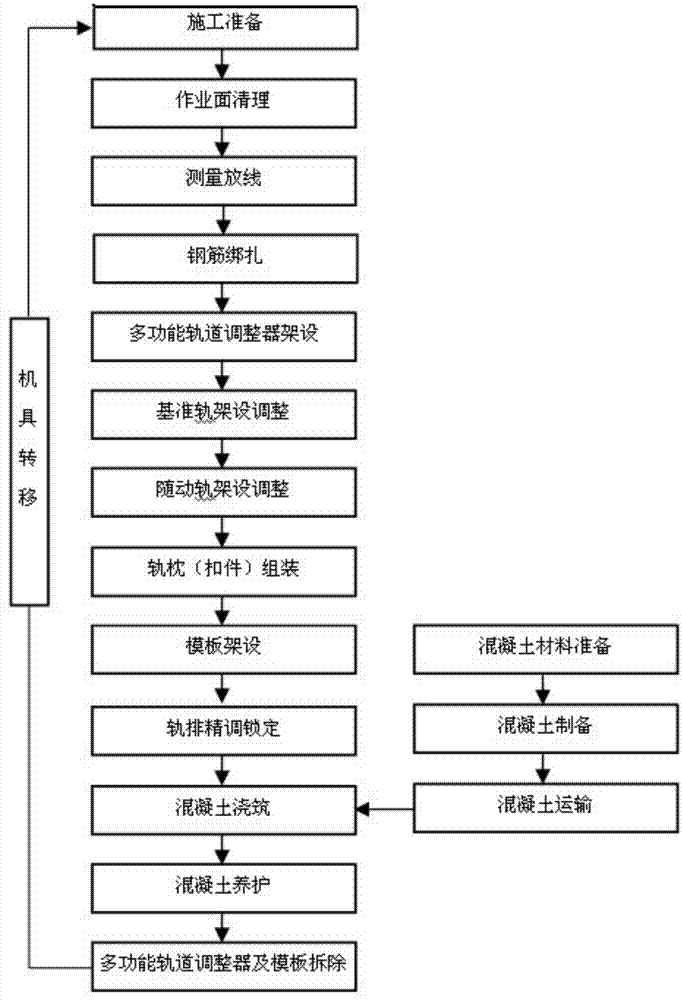

[0060] Figure 1 to Figure 4b shown, including steps:

[0061] Construction preparation:

[0062] Acceptance of bridge projects, layout of measurement control points and retesting, concrete mix ratio test, inspection and evaluation of overall ballast bed laying conditions, etc.

[0063] Work surface cleaning:

[0064] In order to ensure a good connection between the concrete of the overall ballast bed and the bridge deck, the contact surface of the bridge deck is chiseled, the accumulated water is drained, and the scum, dust and sundries are removed with high-pressure air to ensure that the old and new concrete have strong adhesion and ensure Overall track bed construction quality. Check the pre-embedded bars one by one, straighten them according to the design requirements, and derust the corroded steel bars.

[0065] Measuring and setting out:

[0066] Measure and release the control points of the track center line on the beam surface every 10m by measuring the control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com