Roadbed horizontal displacement and vertical displacement comprehensive testing system

A technology of horizontal displacement and vertical displacement, which is applied in foundation structure test, on-site foundation soil survey, foundation structure engineering, etc. It can solve problems affecting subgrade deformation evaluation, inaccuracy, waste of resources, etc., and reduce test cost , compact structure, easy to protect the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

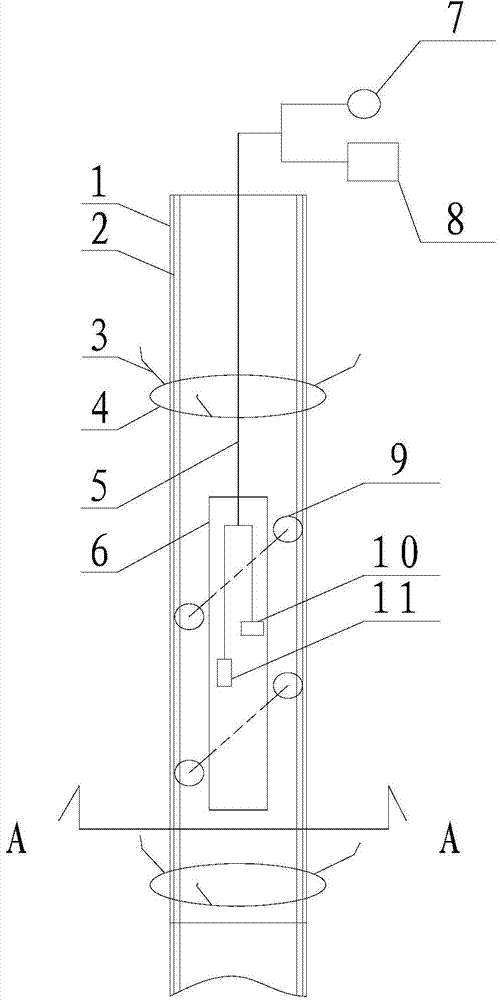

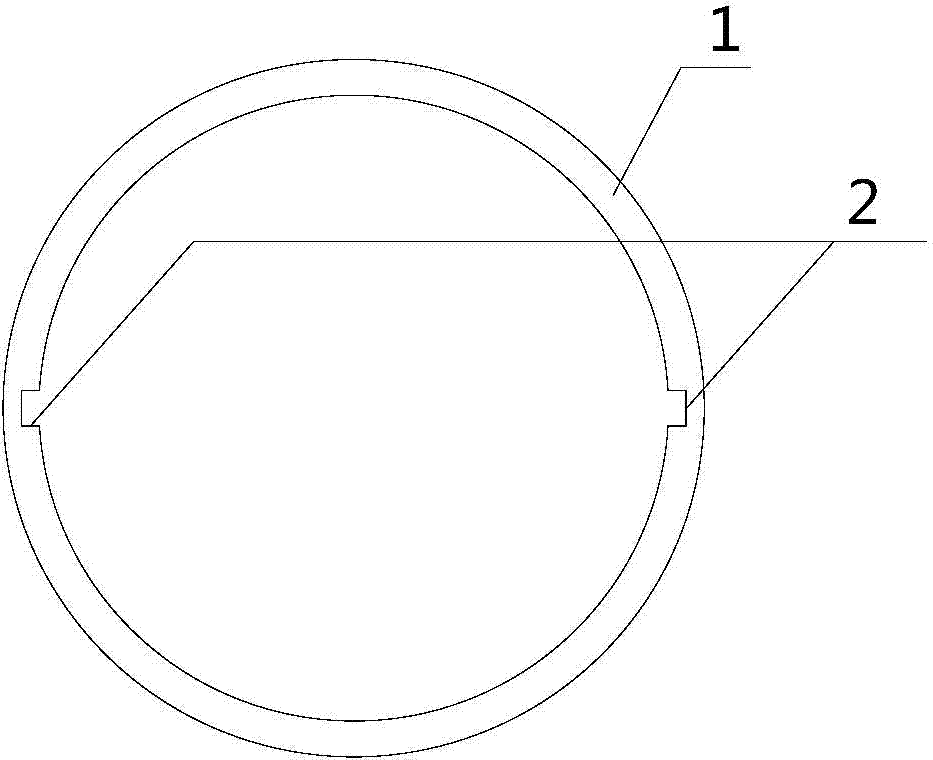

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings. figure 1 and figure 2 The basic structure of the present invention is shown. As shown in the figure, the roadbed horizontal displacement and vertical displacement comprehensive test system involved in the present invention, the roadbed horizontal displacement and vertical displacement comprehensive test system involved in the present invention, includes a test tube 1, a settlement magnetic ring 4, a measuring probe 6, a double Core cable 5, electromagnetic intensity indicator 7, horizontal displacement indicator 8. The test tube 1 is vertically arranged in the subgrade borehole, the test tube 1 is covered with a subsidence magnetic ring 4, the measuring probe 6 is set in the test tube 1, and the angle sensor 10 and the magnetic field strength sensor 11 in the measuring probe 6 pass through a two-core cable. 5 are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com