Functional light wallboard with soundproof rock wool

A technology of rock wool and wall panels, which is applied to building components, buildings, building structures, etc., can solve problems such as poor corrosion resistance, high demand for on-site construction personnel, and unguaranteed construction quality, so as to ensure construction quality and save energy. The effect of human and material resources and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described in detail below in conjunction with specific embodiments.

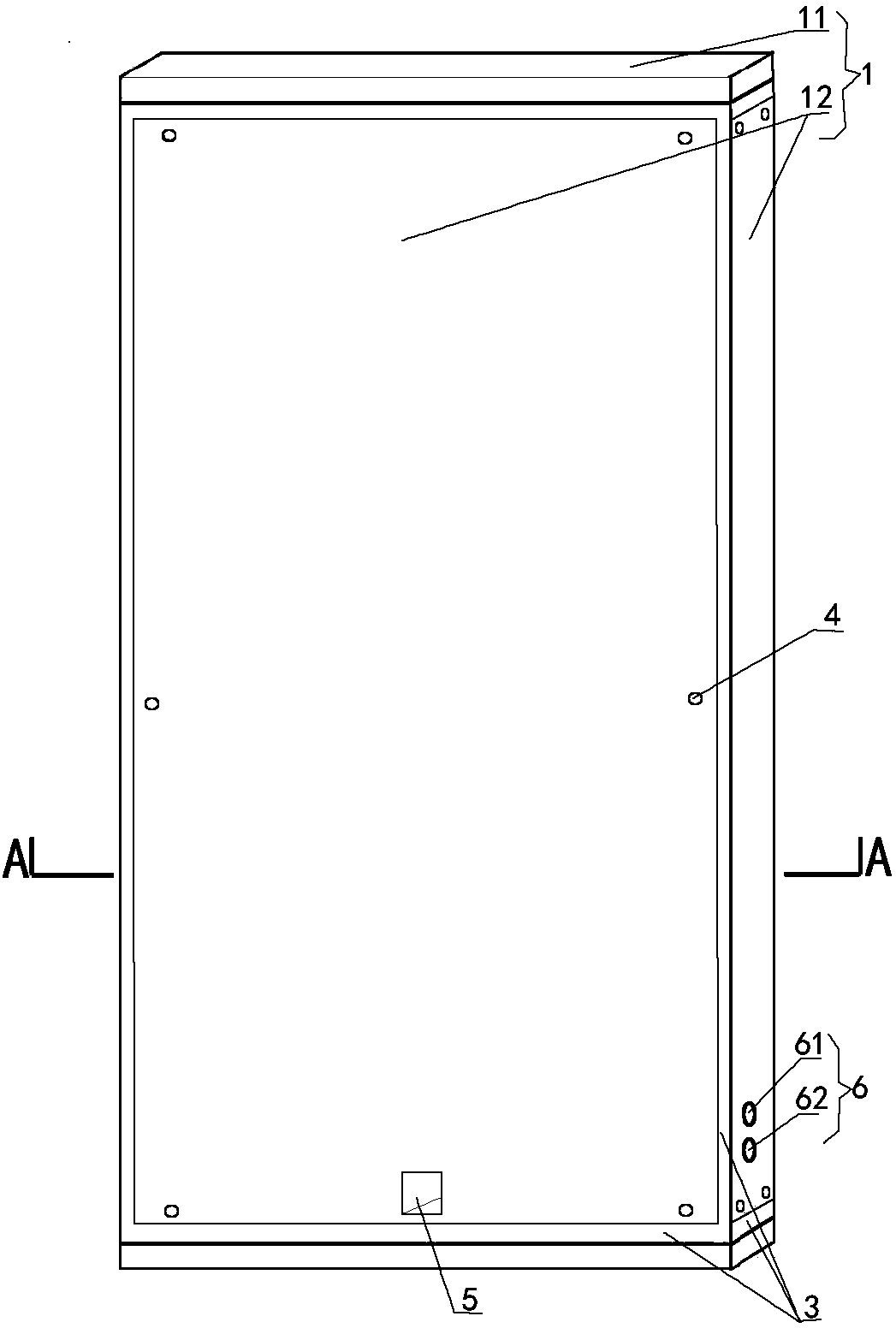

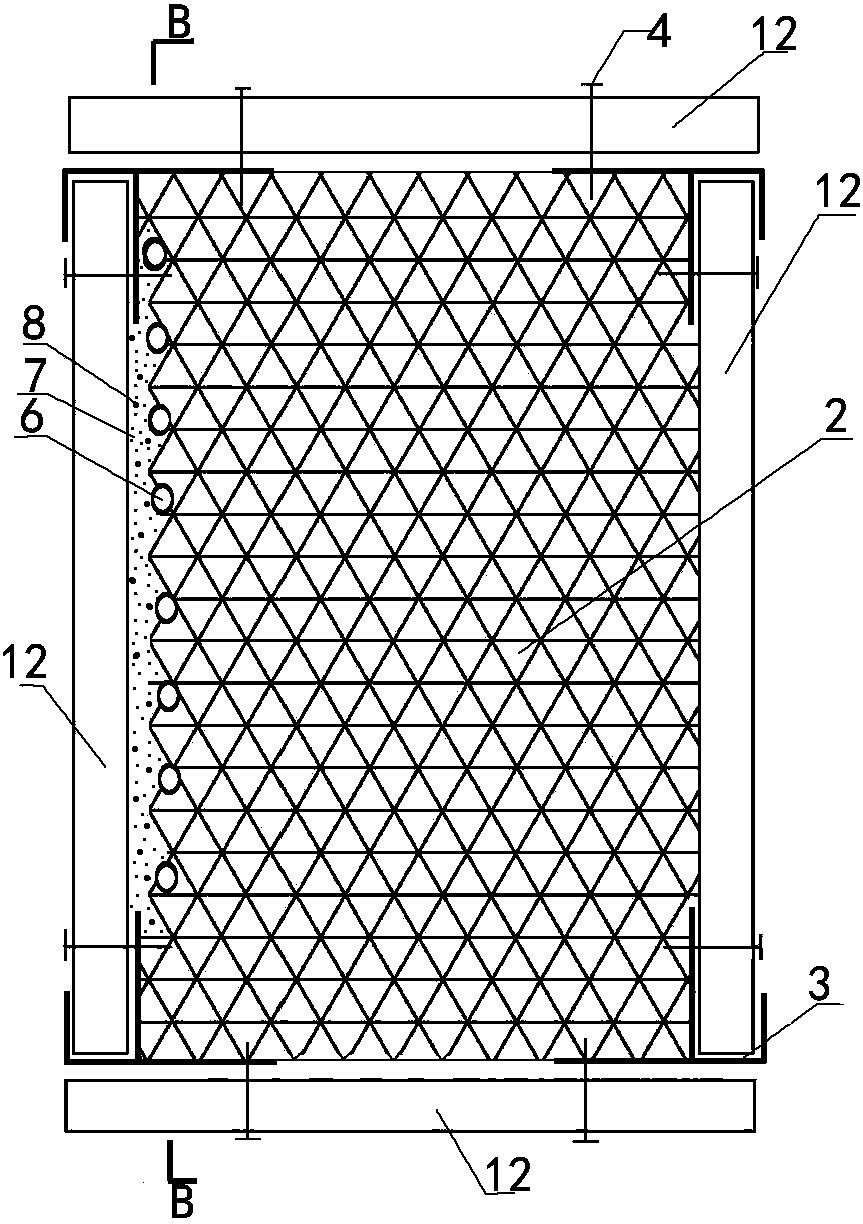

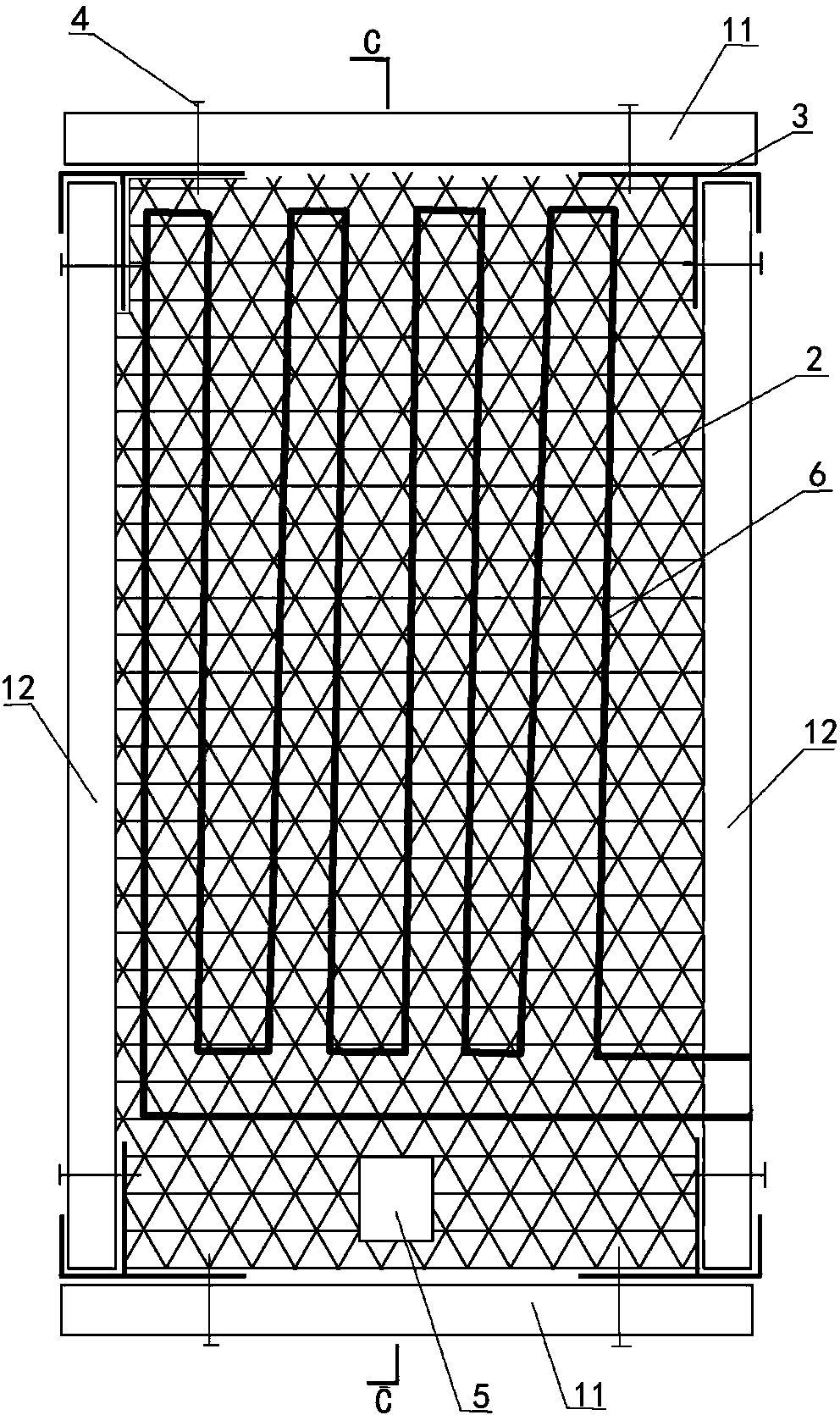

[0027] Such as Figure 1 to Figure 5 As shown, a light-weight sound-insulating rock wool functional wallboard includes a thermal insulation material 2 and an enclosure structure 1 surrounding the thermal insulation material. It is characterized in that: the enclosure structure 1 is a silicon-calcium board that forms a closed cavity. It includes two calcium-silicon boards 11 on the bottom and four calcium-silicon boards 12 on the sides. The airtight cavity is filled with thermal insulation material 2, and the thermal insulation material 2 is rock wool. Adhesive glue is used for bonding; the four edges of the calcium silicon plate 11 on the side are covered with an aluminum alloy frame 3, such as Figure 5 As shown, the cross-section of the aluminum alloy frame 3 is a horizontal F shape, including a frame body 31 and two parallel stoppers 32 perpendicular to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com